Composite mineral powder capable of reducing size shrinkage rate of plastic as well as preparation method and application of composite mineral powder

A technology for compounding minerals and mineral powders, applied in chemical instruments and methods, dyeing organosilicon compound treatment, dyeing polymer organic compound treatment, etc. Large bonding surface, reduced agglomeration, and uniform composite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

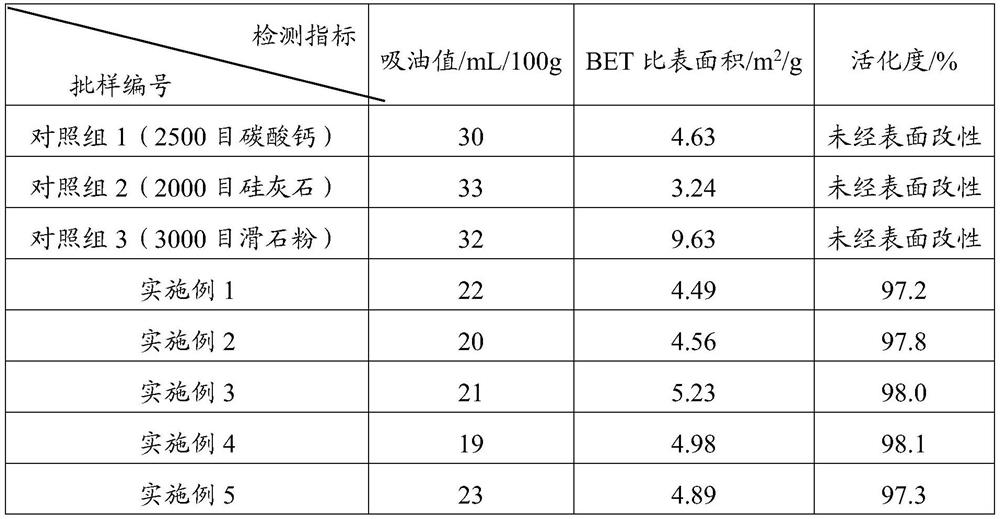

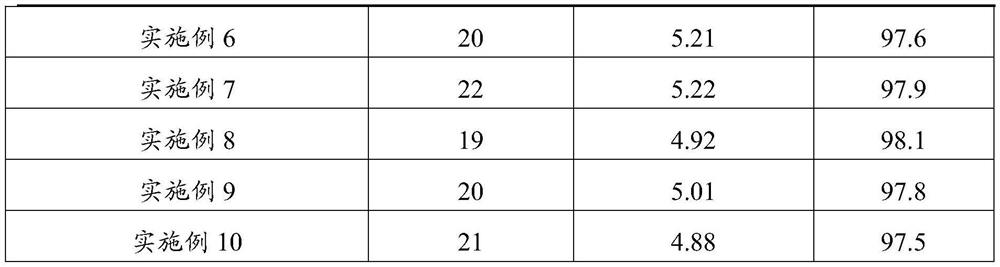

Examples

preparation example Construction

[0049] The present invention provides a preparation method for the composite mineral powder described in the above scheme, comprising the following steps:

[0050] Mix mineral powder, composite dispersant and water to obtain composite slurry;

[0051] adding a pH regulator and an antistatic agent to the composite slurry, drying the resulting slurry to obtain a powder;

[0052] The powder is mixed with a surface modifying agent for modification to obtain a composite mineral powder that reduces the size shrinkage of plastics.

[0053] The invention mixes mineral powder, composite dispersant and water to obtain composite slurry. In the present invention, the mineral powder is preferably mixed with water, and then a composite dispersant is added to obtain a composite slurry. According to the invention, the mixing is preferably carried out in a mixing tank. In the present invention, the solid content of the composite slurry is preferably 30-50%, more preferably 45-45%. Because ...

Embodiment 1

[0065] Silica powder: talcum powder: wollastonite powder is formulated into a slurry with a solid content of 45% in a mass ratio of 1:5:5 and water, and 10‰ of a composite dispersant (specifically ethylene glycol, sodium polyacrylate and Sodium lauryl sulfate, the mass ratio of the three is 1:1:1); under low-speed stirring conditions (stirring speed 60r / min), add 6‰ pH regulator (being citric acid and tartaric acid , the mass ratio of citric acid and tartaric acid is 1:3), 6‰ of octadecyltrimethylammonium chloride, adjust the pH value to 8.5; The temperature is 330°C, the air outlet temperature is 130°C, and the speed of the rotating blade is 450r / min; the dried powder is added with 1.5% oligomeric short-chain alkylsilane coupling agent (Evonik's 9896) and 0.9% fatty acid polyoxyethylene ester for surface modification, the modification temperature was 135° C., and the modification time was 45 min; collected and packaged to obtain composite mineral powder.

Embodiment 2

[0067] Silica powder: talcum powder: wollastonite powder is formulated into a slurry with a solid content of 40% in a mass ratio of 1:6:6 and water, and 9‰ of a composite dispersant (specifically ethylene glycol, sodium polyacrylate and Sodium lauryl sulfate, the corresponding mass ratio of the three is 1:2:1); under low-speed stirring conditions (stirring speed 65r / min), add 5‰ pH regulator (being citric acid and Tartaric acid, the mass ratio of citric acid and tartaric acid is 1:2), 6‰ of octadecyltrimethylammonium chloride, adjust the pH value to 8.5; the inlet air temperature of flash drying is 330°C, and the outlet air temperature is 130°C , the rotating blade speed is 450r / min; the dried powder is added with 1.2% oligomeric short-chain alkyl silane coupling agent (Evonik's 9896) and 1.2% fatty acid polyoxyethylene ester for surface modification, the modification temperature is 130° C., and the modification time is 50 min; collect, pack, and obtain composite mineral powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com