Cryptomelane type mixed manganese oxide catalyst for removing soot of diesel vehicle through oxidation

A technology of cryptopotassium manganese ore and manganese oxide, which is applied in the application field of catalytic oxidation to remove soot particles from diesel vehicles, can solve the problems of low melting point of alkali metal catalyst, corrosion of ceramic DPF, poor stability, etc., and achieves mild preparation conditions and simple method Ease of operation, large pore volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] (1) Weigh 3.25g potassium permanganate (KMnO 4 ) was dissolved in 75 mL of deionized water, recorded as solution Ⅰ; weighed 5.5 g of manganese acetate (MnC 4 h 6 o 4 4H 2 O) Dissolve in 20 mL deionized water, and record it as solution II;

[0023] (2) Stir and mix solution II and 42 mL acetic acid solution (6 wt.%) first, then add solution I dropwise;

[0024] (3) The mixed solution obtained in step (2) was heated to reflux at 50° C. while stirring for 36 h. Wash with absolute ethanol and deionized water successively, dry at 80°C overnight, and finally calcined at 550°C for 5h. After cooling down to room temperature, it was taken out, and the obtained sample was a cryptopotassium manganese-type mixed manganese oxide catalyst, referred to as KMnOx.

example 2

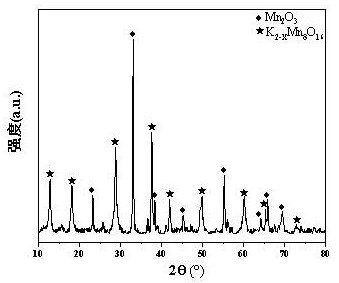

[0026] figure 1 is the XRD spectrum of the prepared sample. XRD analysis found that the as-prepared KMnO x is made of cryptopotassium manganese (K 2-x mn 8 o 16 ) and Mn 2 o 3 Composed of mixed manganese oxides.

example 3

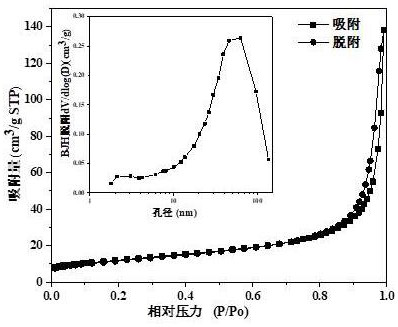

[0028] The specific surface area, pore size distribution and pore volume of the catalyst were carried out on ASAP 2460 automatic specific surface area and porosity analyzer produced by Micromeritics, USA. KMnO x Sample N 2 The adsorption-desorption curve conforms to the type II isotherm in IUPAC, with a hysteresis loop of type H3 in the relatively high pressure range, and in the P / P 0 There is no adsorption limitation when it is close to 1, which indicates that there is a slit-shaped macroporous structure in the sample. The specific surface area of the sample (S BET ), pore volume (V p ) and average pore diameter (D p ) are 42.6 m 2 / g, 0.21 cm 3 / g and 35.6 nm. From the pore size distribution curve ( figure 2 ) shows that the sample is a hierarchical porous structure with micropores, mesopores and macropores, and their proportions are 2%, 55% and 43%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com