Preparation of modified magnetic zeolite imidazole framework material and adsorption of trace ceftazidime in water

A zeolite imidazole framework, magnetic technology, applied in the direction of adsorption water/sewage treatment, water pollutants, other chemical processes, etc. smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

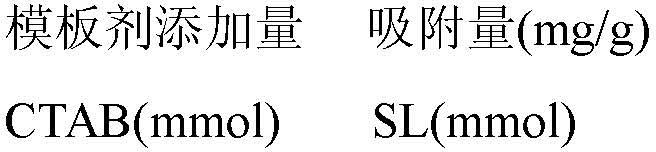

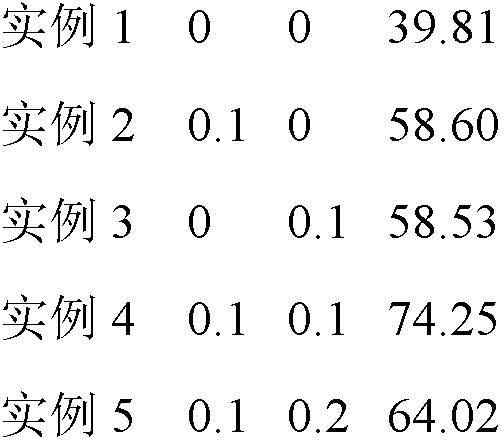

example 1

[0013] Example 1. Weigh 50 ml ethanol, 10 ml deionized water, 10 ml (25%) ammonia water, 0.3 g Fe3O4, 20 ml TEOS, ultrasonicate in a water bath at 40°C and stir for 3 hours. After the reaction, filter the product and ultrasonicate it with deionized water and ethanol Washed three times, dried in a constant temperature drying oven at 60 °C for 12 h to obtain SiO2@Fe3O4 magnetic particles. Weigh 0.405g zinc nitrate hexahydrate, 0.2 gSiO2@Fe3O4, 20 ml methanol to prepare mixed methanol solution A; 0.265 g 2-methylimidazole, 0 mmol CTAB, 0 mmolSL, 20 ml methanol to prepare mixed methanol solution B; mix After stirring at room temperature for 6 h, the product was filtered and ultrasonically washed with deionized water and ethanol three times, dried at 80 °C for 12 h, calcined at 150 °C for 1 h under N2 environment, and then calcined at 500 °C for 2 h to remove the template agent. The product obtained after cooling down is ZIF-8@SiO2@Fe3O4. Add 1mg ZIF-8@SiO2@Fe3O4 to 200 ml of 1mg / ...

example 2

[0014] Example 2. Weigh 50 ml ethanol, 10 ml deionized water, 10 ml (25%) ammonia water, 0.3 g Fe3O4, 20 ml TEOS, ultrasonicate in a water bath at 40°C and stir for 3 hours. After the reaction, filter the product and ultrasonicate it with deionized water and ethanol Washed three times, dried in a constant temperature drying oven at 60 °C for 12 h to obtain SiO2@Fe3O4 magnetic particles. Weigh 0.425g zinc nitrate hexahydrate, 0.2 gSiO2@Fe3O4, 20 ml methanol to prepare mixed methanol solution A; 0.265 g 2-methylimidazole, 0.1mmolg CTAB, 0mmol SL, 20 ml methanol to prepare mixed methanol solution B; mix After stirring at room temperature for 6 h, the product was filtered and ultrasonically washed with deionized water and ethanol three times, dried at 80 °C for 12 h, calcined at 150 °C for 1 h under N2 environment, and then calcined at 500 °C for 2 h to remove the template agent. The product obtained after cooling down is ZIF-8@SiO2@Fe3O4. Add 1mg ZIF-8@SiO2@Fe3O4 to 200 ml of 1m...

example 3

[0015] Example 3. Weigh 50 ml ethanol, 10 ml deionized water, 10 ml (25%) ammonia water, 0.3 g Fe3O4, 20 ml TEOS, sonicate in a water bath at 40°C and stir for 3 hours. After the reaction, filter the product and sonicate it with deionized water and ethanol Washed three times, dried in a constant temperature drying oven at 60 °C for 12 h to obtain SiO2@Fe3O4 magnetic particles. Weigh 0.405g zinc nitrate hexahydrate, 0.2 gSiO2@Fe3O4, 20 ml methanol to prepare mixed methanol solution A; 0.265 g 2-methylimidazole, 0 mmol CTAB, 0.1 mmol SL, 20 ml methanol to prepare mixed methanol solution B; After mixing, stir at room temperature for 6 h. After the reaction, filter the product and ultrasonically wash it with deionized water and ethanol for 3 times, dry at 80°C for 12 h, calcinate at 150°C for 1 h under N2 environment, and then calcinate at 500°C for 2 h to remove the template. , the product obtained after cooling down is ZIF-8@SiO2@Fe3O4. Add 1mg ZIF-8@SiO2@Fe3O4 to 200 ml of 1mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com