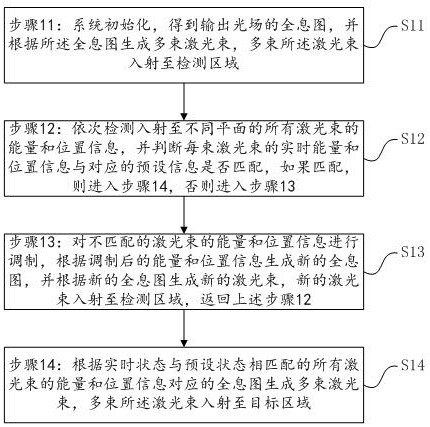

A three-dimensional multi-beam laser parameter control method and system

A laser parameter, multi-beam technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of limited multi-beam, low flexibility, low laser processing efficiency, etc., to eliminate manufacturing and installation errors, reduce The effect of small optical system error and improved laser utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

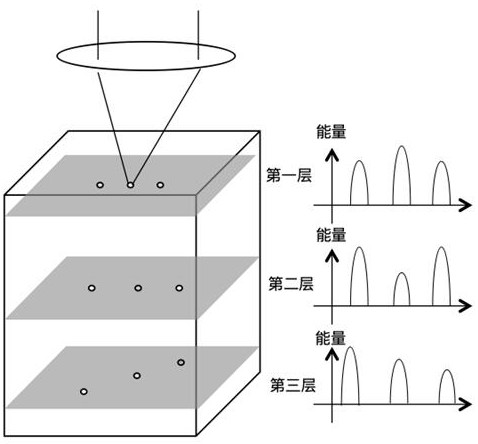

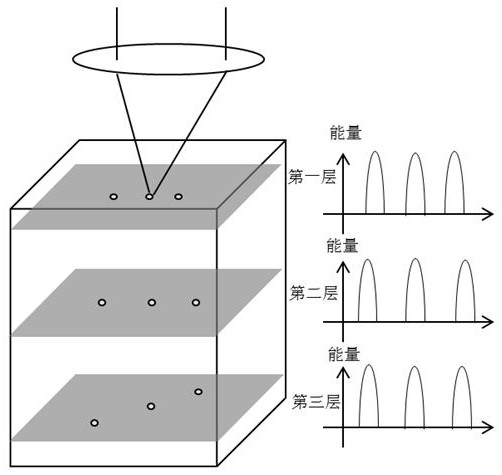

[0069]In this embodiment, the laser parameter control system includes a laser light source, an optical path deflection component, a beam parameter control component, a spot energy and position sensing component 12, and a control terminal 16. The beam parameter control component, spot energy and position sensing The components 12 are respectively connected to the control terminal 16; the control terminal 16 is used to initialize and generate a hologram of the output light field, and load the hologram onto the beam parameter control component; the optical path deflection component is used to Multiple laser beams are incident on the spot energy and position sensing component 12 located in the detection area, or incident on the working plane located in the target area; the beam parameter control component is used to receive the laser output from the laser light source beam, generate multiple laser beams according to the hologram; the spot energy and position sensing component 12 is...

Embodiment 2

[0120] Such as Figure 4 As shown, a three-dimensional multi-beam laser parameter control system includes a laser source 1 for generating coherent laser beams, a beam parameter control component 4, a flip mirror 9, a first focusing component 10, a spot energy and position sensing component 12, The second focusing assembly 14, the three-dimensional motion workbench 15 and the control terminal 16, the laser light source 1, the beam parameter regulation assembly 4 and the flip mirror 9 are sequentially connected in the optical path, and the flip mirror 9 can rotate freely, so that the laser beam passes through the The first focusing component 10 is incident on the spot energy and position sensing component 12, or incident on the workpiece on the three-dimensional motion table 15 via the second focusing component 14, and the first focusing component The distance between the focal point of the laser beam emitted by 10 and the spot energy and position sensing component 12 is relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com