Method for preparing transition metal oxide composite electrode for lithium battery

A composite electrode and transition metal technology, which is applied in battery electrodes, lithium batteries, electrode manufacturing, etc., can solve the problems that the coating layer is difficult to conduct and protect, and affects lithium batteries, so as to improve electrochemical performance and cycle Performance, Erosion Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

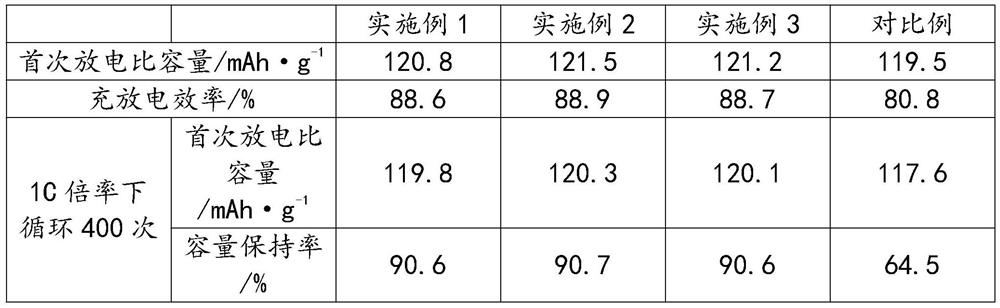

Examples

Embodiment 1

[0027] A method for preparing a transition metal oxide composite electrode for a lithium battery, comprising the steps of:

[0028] S1. Using nickel nitrate hexahydrate and ferric nitrate nonahydrate as raw materials, add them into deionized water at a molar ratio of 1:2.02, mechanically stir at 150r / min for 30min, add metal oxides after fully dissolving, and continue stirring for 110min to obtain a mixed solution;

[0029] S2. Add ammonia water with a mass concentration of 15% to the above mixed solution dropwise, adjust the pH value of the mixed solution to 9.0, continue stirring for 30 minutes, filter with suction, wash, and dry the product in a blast drying oven at 80°C to obtain a precursor Material;

[0030] S3. Put the precursor material in a tube furnace, raise the temperature of the tube furnace at a rate of 30°C / min, raise the temperature to 600°C, sinter in the air for 3 hours, cool to room temperature with the furnace, and discharge the material to prepare Get coa...

Embodiment 2

[0033] A method for preparing a transition metal oxide composite electrode for a lithium battery, comprising the steps of:

[0034] S1. Using nickel nitrate hexahydrate and ferric nitrate nonahydrate as raw materials, add them into deionized water at a molar ratio of 1:2.02, mechanically stir at 150r / min for 35min, add metal oxides after fully dissolving, and continue stirring for 115min to obtain a mixed solution;

[0035] S2. Add ammonia water with a mass concentration of 15% to the above mixed solution dropwise, adjust the pH value of the mixed solution to 9.1, continue to stir for 35 minutes, filter with suction, wash, and dry the product in a blast drying oven at 80°C to obtain a precursor Material;

[0036] S3. Put the precursor material in the tube furnace, raise the temperature of the tube furnace at a rate of 30°C / min, raise the temperature to 630°C, sinter in the air for 3.5 hours, cool to room temperature with the furnace, and discharge the material. Prepare coated...

Embodiment 3

[0039] A method for preparing a transition metal oxide composite electrode for a lithium battery, comprising the steps of:

[0040] S1. Using nickel nitrate hexahydrate and ferric nitrate nonahydrate as raw materials, add them into deionized water at a molar ratio of 1:2.02, mechanically stir at 150r / min for 40min, add metal oxides after fully dissolving, and continue stirring for 120min to obtain a mixed solution;

[0041] S2. Add ammonia water with a mass concentration of 15% to the above mixed solution dropwise, adjust the pH value of the mixed solution to 9.2, continue to stir for 40 minutes, filter with suction, wash, and dry the product in a blast drying oven at 80°C to obtain a precursor Material;

[0042] S3. Put the precursor material in a tube furnace, raise the temperature of the tube furnace at a rate of 30°C / min, raise the temperature to 650°C, sinter in the air for 4 hours, cool to room temperature with the furnace, and discharge the material to prepare Get coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com