Automobile tail gas exhaust pipe with waste gas purification function

A technology for purifying automobile exhaust and exhaust gas, applied in exhaust devices, mechanical equipment, engine components, etc., can solve problems such as harming the natural environment, deteriorating air quality, affecting physical health, etc., to reduce the content of hazardous substances and reduce the cost of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

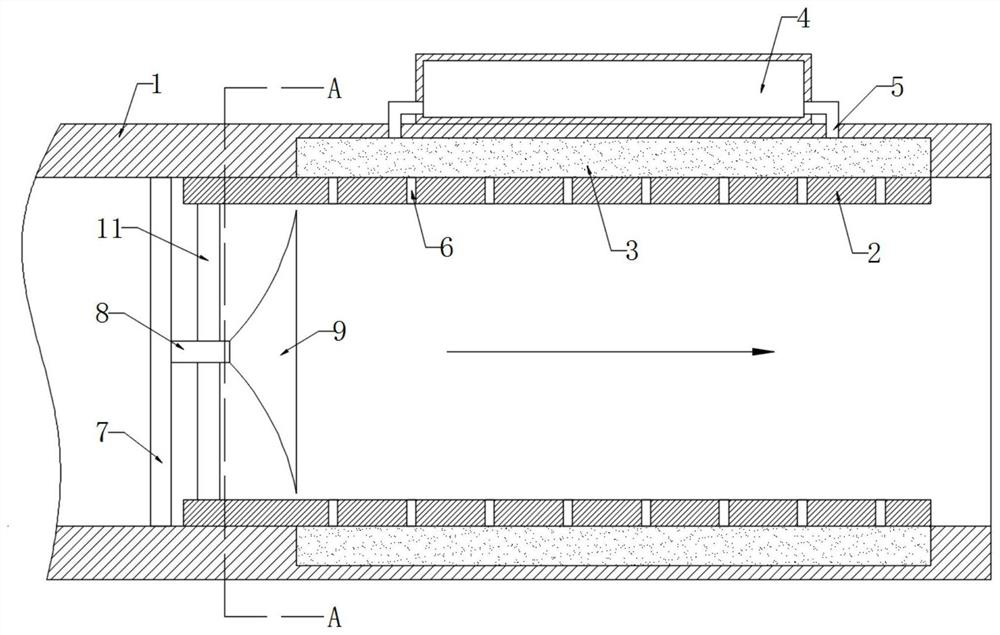

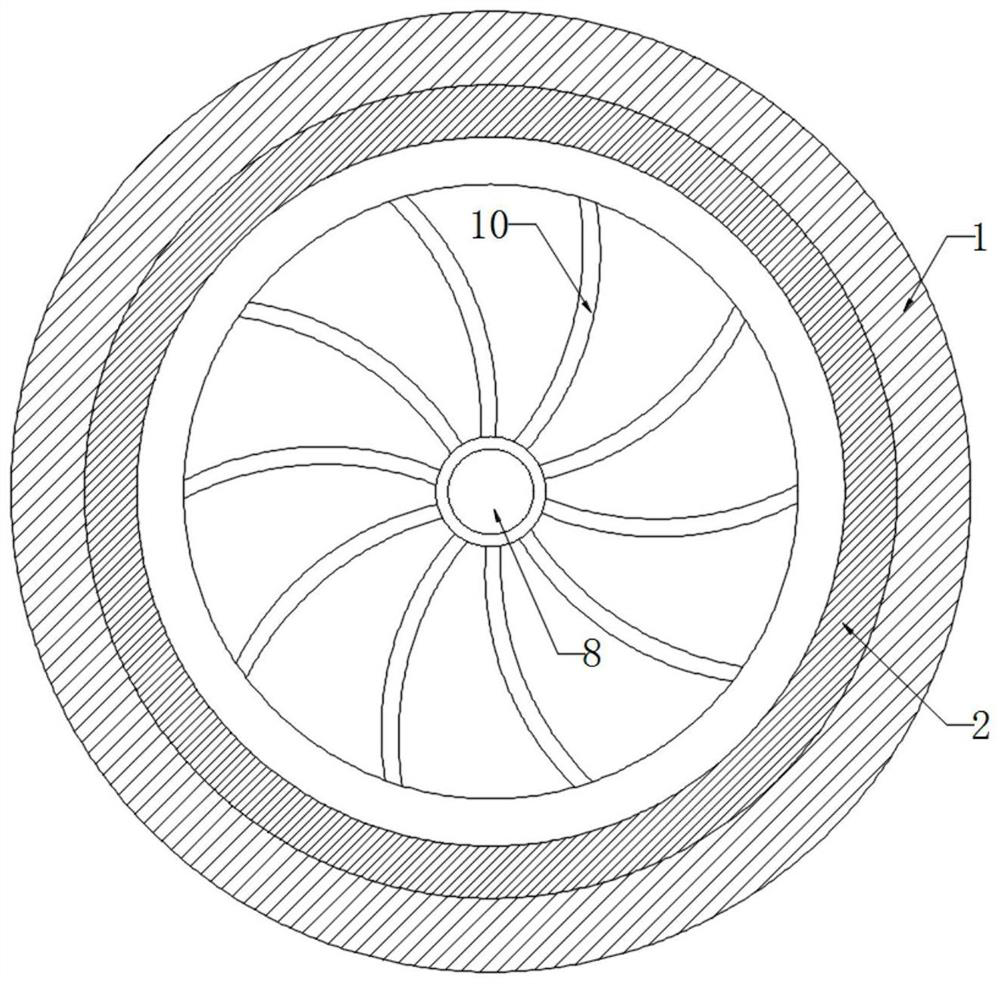

[0020] refer to Figure 1-2 , an exhaust pipe for automobile exhaust with exhaust gas purification function, comprising a pipe body 1, the inner wall of the pipe body 1 is rotatably connected with a ring 2, the inner top of the pipe body 1 is embedded with water-absorbent cotton 3, and the upper end of the pipe body 1 is fixedly connected to the storage tank. The water tank 4 and the inner wall of the water storage tank 4 are connected to the upper end of the water-absorbent cotton 3 through the drain pipe 5, and the side wall of the ring 2 is provided with a plurality of capillary holes 6. Further, under the capillary effect, the capillary holes 6 can continuously flow from the water-absorbent cotton 3. To absorb water, the inner wall of the pipe body 1 is fixedly connected with a vertical rod 7, and the side wall of the vertical rod 7 is connected with a conical block 9 through a rotating shaft 8, and a plurality of diversion grooves 10 are arranged around the side wall of th...

Embodiment 2

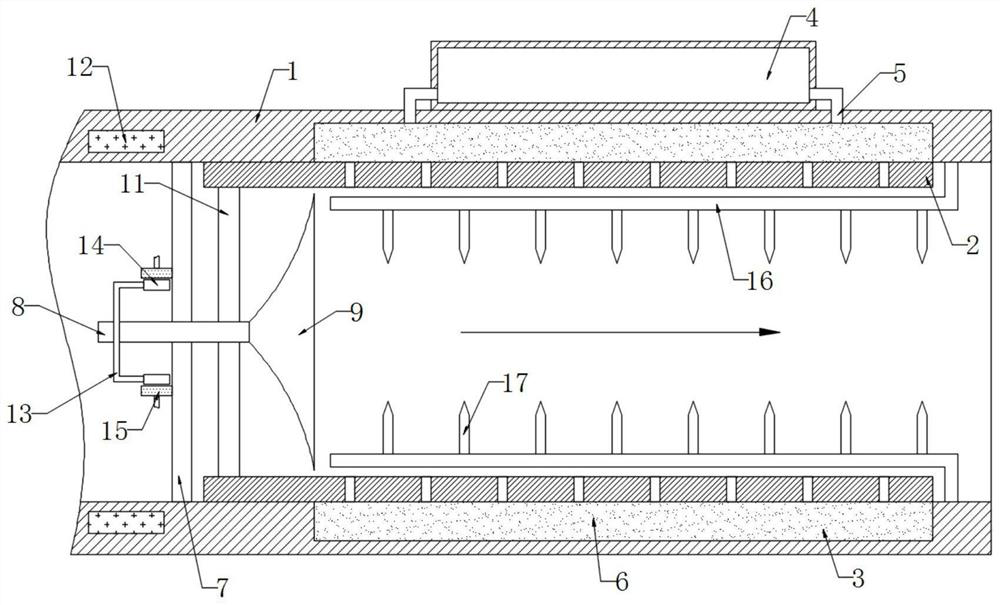

[0023] refer to image 3 , and the difference from Embodiment 1 is that the inner wall of the tube body 1 is symmetrically embedded with permanent magnets 12, and the magnetic poles of the two permanent magnets 12 facing each other are opposite, so that a magnetic field circuit is formed between the two permanent magnets 12, thereby realizing For the cutting of magnetic induction lines, the end of the rotating shaft 8 away from the tapered block 9 runs through the side wall of the vertical bar 7 and is inserted with a lead frame 13. Both ends of the lead frame 13 are fixedly connected with arc-shaped pieces 14, and the inner wall of the pipe body 1 is fixed symmetrically. A brush 15 is connected, and the arc-shaped piece 14 is attached to the brush 15. Two collector plates 16 are symmetrically fixedly connected to the inner wall of the tube body 1, and the two collector plates 16 are coupled and connected to both ends of the lead frame 13 respectively. A plurality of discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com