Novel epoxy resin paint and application thereof

A technology of epoxy resin paint and water-based epoxy resin, applied in epoxy resin paint, coating, fireproof paint, etc., can solve the problems of heat resistance and poor heat dissipation, and achieve good environmental protection, increased thermal conductivity, and heat transfer. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

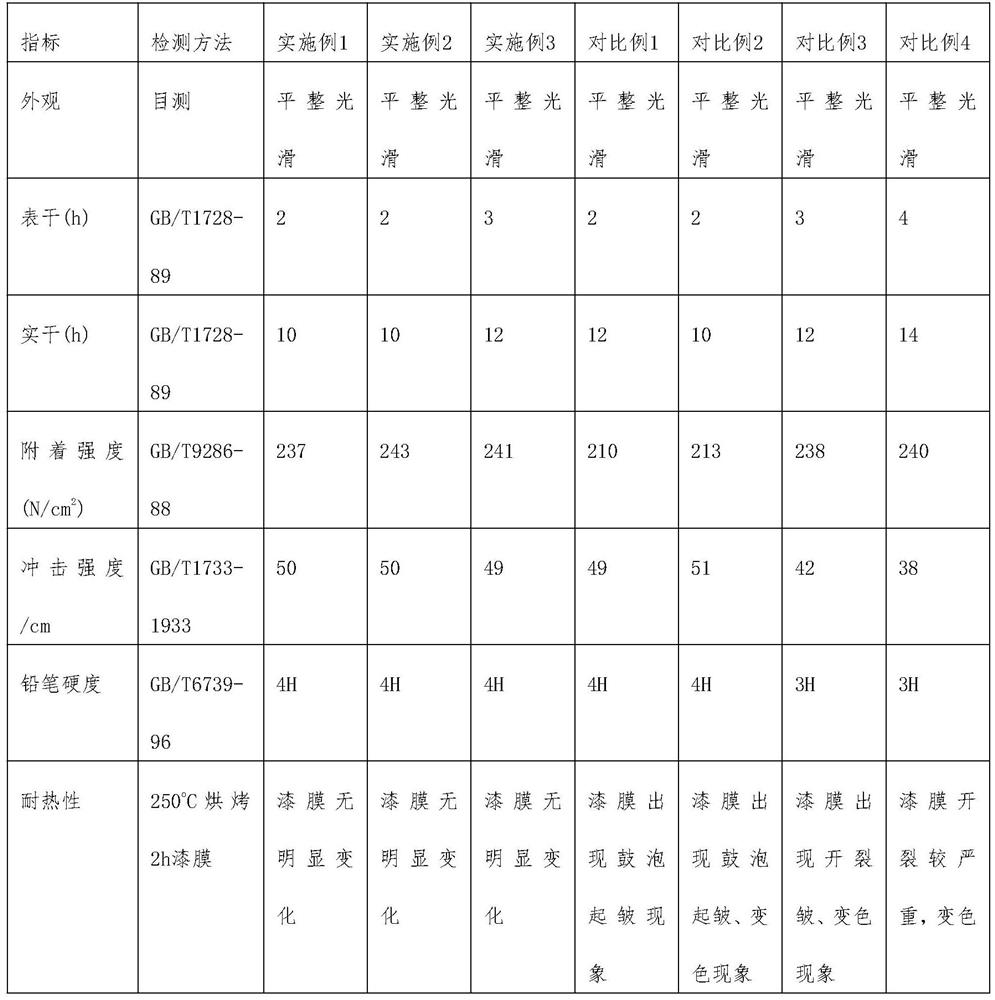

Examples

Embodiment 1

[0017] Embodiment 1 novel epoxy resin paint

[0018] Preparation of modified water-based epoxy resin: take diethanolamine-modified water-based epoxy resin and 2% by mass of silane coupling agent, stir and heat to 30-35°C, add microcrystalline cellulose with 0.1% by mass of water-based epoxy resin, Stir and process for 8-10min.

[0019] Raw materials (by weight): 80 parts of modified water-based epoxy resins, 30 parts of polylactic acid-epoxy soybean oil copolymers, 5 parts of nano-carbon fibers, 60 parts of epoxy resin curing agents, 3 parts of cooling agents, 110 parts of water . Among them, the epoxy resin curing agent is composed of alkenyl succinic anhydride and water-based polyurethane in a mass ratio of 4:1; the cooling agent is composed of alumina and nano-calcium carbonate in a mass ratio of 2:1.

[0020] Preparation of epoxy resin paint: mix modified water-based epoxy resin, modified epoxy soybean oil, and water and heat to 35-40°C, heat preservation for 25 minutes,...

Embodiment 2

[0022] Preparation of modified water-based epoxy resin: take diethanolamine-modified water-based epoxy resin and 2.5% by mass of silane coupling agent, stir and heat to 30-35°C, add microcrystalline cellulose with 0.1% by mass of water-based epoxy resin, Stir and process for 8-10min.

[0023] Raw materials (by weight): 85 parts of modified water-based epoxy resin, 32 parts of polylactic acid-epoxy soybean oil copolymer, 6 parts of nano-carbon fiber, 70 parts of epoxy resin curing agent, 56 parts of cooling agent, and 120 parts of water. Among them, the epoxy resin curing agent is composed of alkenyl succinic anhydride and water-based polyurethane in a mass ratio of 4:1; the cooling agent is composed of alumina and nano-calcium carbonate in a mass ratio of 2:1.

[0024] Preparation of epoxy resin paint: Mix modified water-based epoxy resin, modified epoxy soybean oil, and water and heat to 35-40°C, heat preservation for 30 minutes, after cooling, add fixative, cooling agent, an...

Embodiment 3

[0026] Preparation of modified water-based epoxy resin: take diethanolamine-modified water-based epoxy resin and 3% by mass of silane coupling agent, stir and heat to 30-35°C, add microcrystalline cellulose with 0.1% by mass of water-based epoxy resin, Stir for 10 minutes and you're done.

[0027] Raw materials (by weight): 100 parts of modified water-based epoxy resins, 40 parts of polylactic acid-epoxy soybean oil copolymers, 8 parts of nano-carbon fibers, 80 parts of epoxy resin curing agents, 6 parts of cooling agents, 160 parts of water . Among them, the epoxy resin curing agent is composed of alkenyl succinic anhydride and water-based polyurethane in a mass ratio of 4:1; the cooling agent is composed of alumina and nano-calcium carbonate in a mass ratio of 2:1.

[0028] Preparation of epoxy resin paint: Mix modified water-based epoxy resin, modified epoxy soybean oil, and water and heat to 35-40°C, heat preservation for 30 minutes, after cooling, add fixative, cooling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com