A precision welding equipment for pipe flanges

A precision welding and pipe flange technology, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of time-consuming and labor-intensive manual welding of flanges, high skill requirements for operators, and can only be used in fixed places. , to achieve the effect of reducing labor intensity, low requirements for operating skills, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

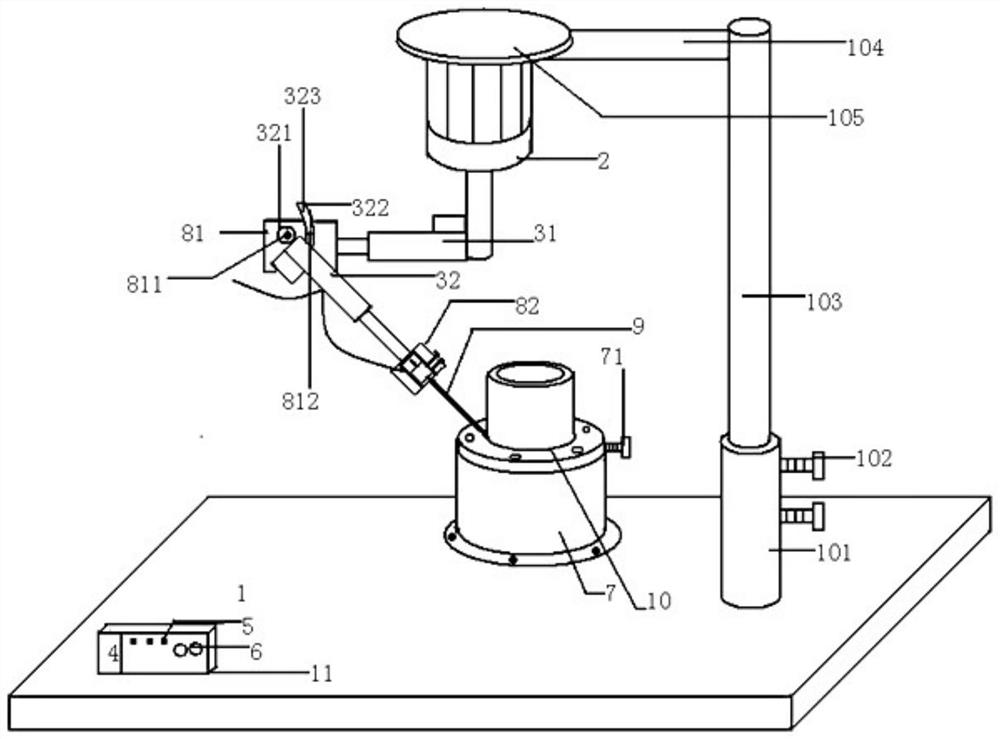

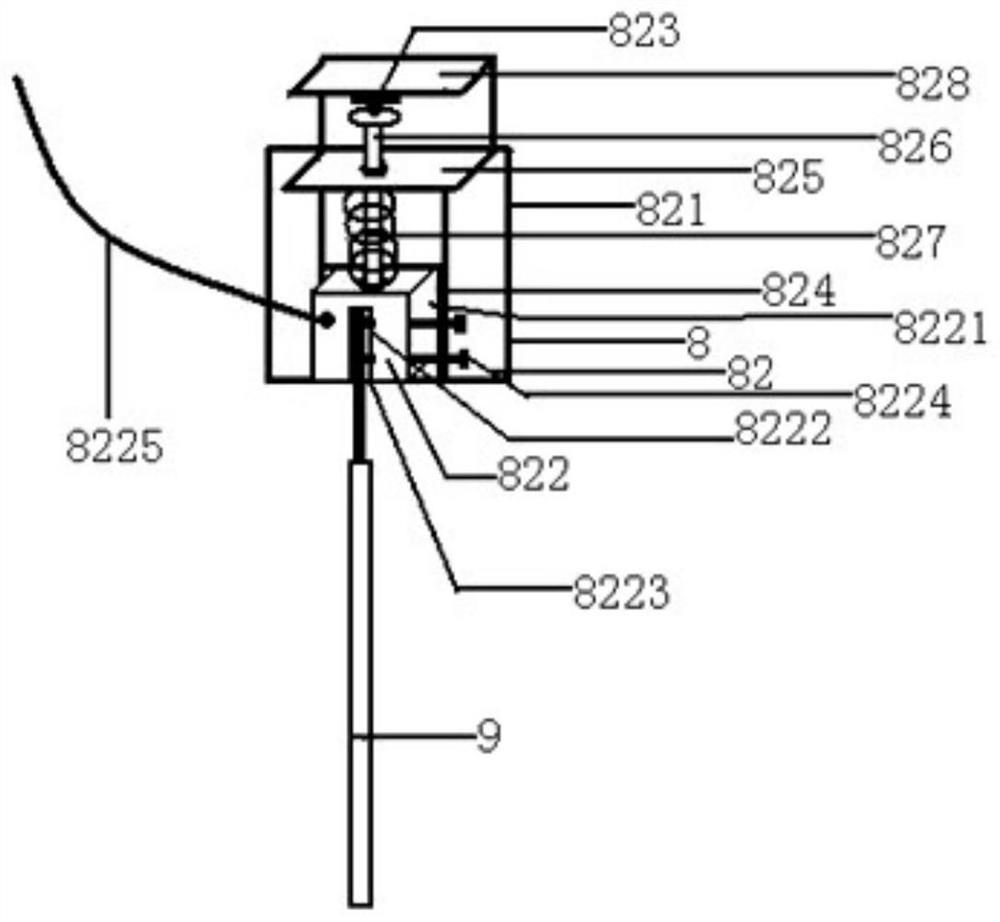

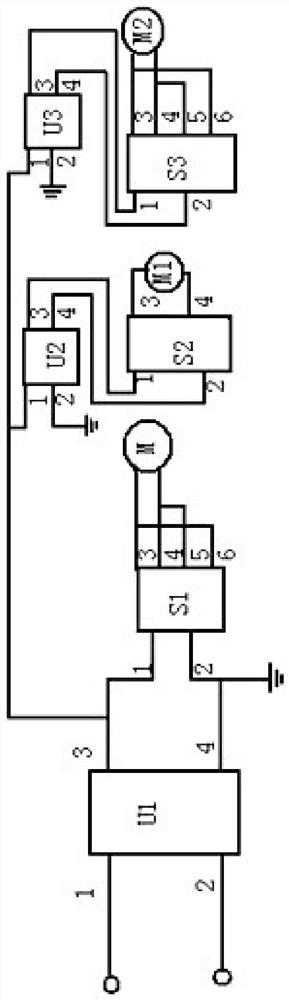

[0016] figure 1 , 2 As shown in , a pipe flange precision welding equipment includes a welding machine body, a rectangular bottom plate 1, a motor reduction mechanism 2, electric telescopic rods 31 and 32, a switching power supply 4, three power switches 5, and two sets of speed control switches 6 , fixed sleeve 7; also has welding rod fixing detection mechanism 8; the upper middle part of the right side end of described base plate 1 is vertically welded with a support tube 101, and the upper and lower parts of the right side end of support tube 101 respectively have an internal thread opening, A manual screw rod 102 is respectively screwed into the perforation; a movable pipe 103 is inserted in the inner vertical sleeve of the support pipe 101, and the outer diameter of the movable pipe 103 is slightly smaller than the inner diameter of the support pipe 101 (by adjusting the movable pipe 103 to be positioned at the The height in 101 can adjust the height of the motor reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com