Mask disinfection device for mask production

A technology for disinfection devices and masks, applied in disinfection, water supply devices, clothing, etc., can solve the problems of trouble, long mask disinfection cycle, affecting mask production efficiency, etc., and achieve the effect of improving disinfection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

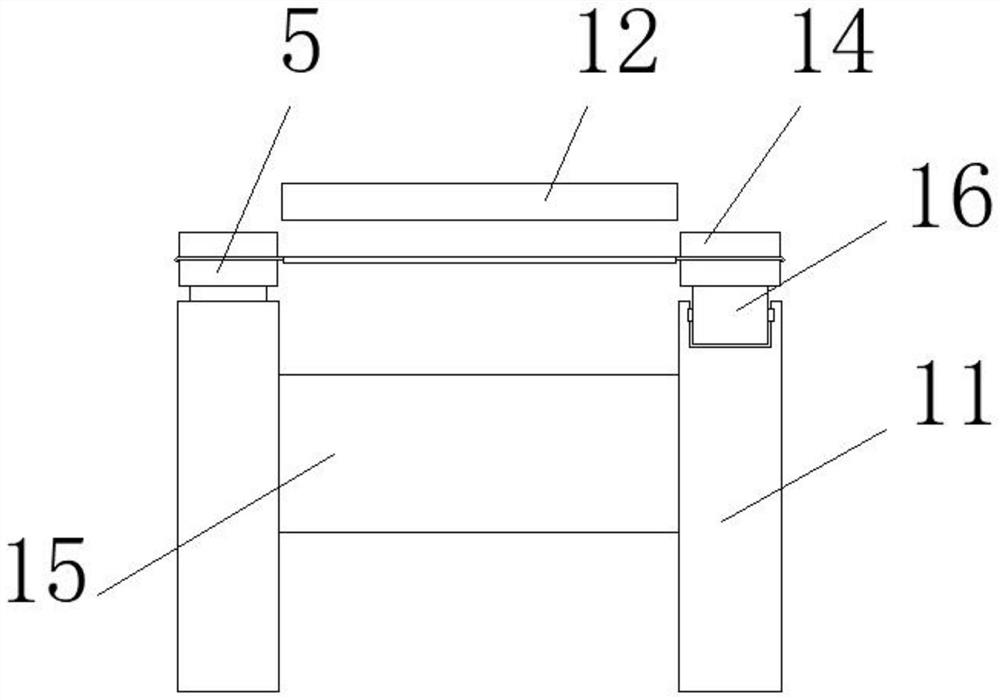

[0023] refer to Figure 1-3 , a mask disinfection device for mask production, comprising a device main box 1, one end of the device main box 1 is bolt-connected with a discharge port 2, and the two ends of the inner cavity of the device main box 1 are respectively provided with a first delivery wheel 3 and a second Conveying wheel 4, the side of first conveying wheel 3 and the second conveying wheel 4 are nested with conveying belt 5, the inner side of first conveying wheel 3 is provided with synchronous belt 17, and the top surface of conveying belt 5 is provided with extruding belt 14, The inner side of the extrusion belt 14 is provided with a power pulley 13, and the bottom surface bolt of the device main box 1 is connected with a driving motor 6, and the driving motor 6 is connected with a driving pulley 7 through a belt, and the driving pulley 7 is meshed with the inner side of the conveying belt 5, and the first conveying The bottom of the wheel 3 is provided with a dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com