High-voltage lithium ion battery electrolyte additive and electrolyte

An electrolyte additive and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve problems such as shortening battery life, prone to oxidation reactions in the electrolyte, and capacity decay of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

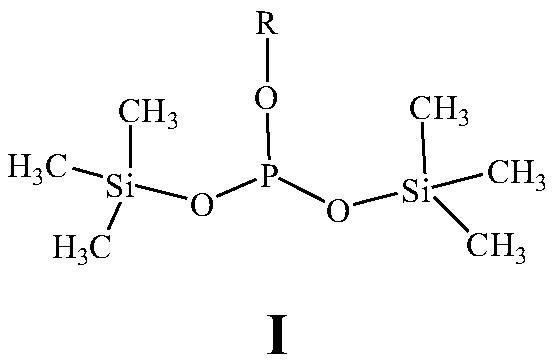

Method used

Image

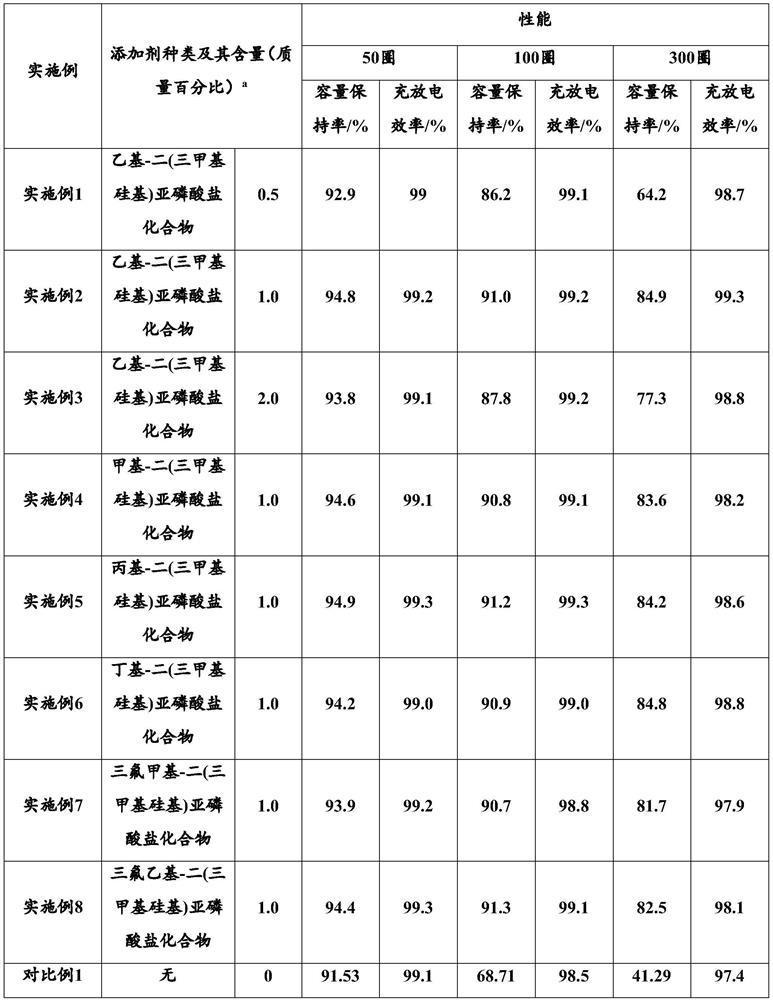

Examples

Embodiment 1

[0024] Electrolyte preparation: In an argon-filled glove box (moisture 6 solution, and then add an ethyl-bis(trimethylsilyl)phosphite compound accounting for 0.5% of the mass ratio of the electrolyte, and stir evenly to obtain the lithium-ion battery electrolyte of Example 1.

[0025] Preparation of the positive electrode sheet: fully stir and mix the positive electrode active material lithium-rich manganese-based material, the conductive agent acetylene black, and the binder polyvinylidene fluoride (PVDF) in the N-methylpyrrolidone system at a mass ratio of 80:10:10 Evenly, coated on the positive electrode current collector Al foil, dried and cold pressed to obtain the positive electrode sheet.

[0026] Preparation of isolation membrane: PE porous polymer film is used as isolation membrane.

[0027] Preparation of lithium ion battery: the obtained positive electrode sheet is placed in an oven at a certain temperature to dry it and then moved into a glove box. Then put the pr...

Embodiment 2

[0029] Electrolyte preparation: In an argon-filled glove box (moisture 6 Electrolyte solution, then add ethyl-bis(trimethylsilyl)phosphite compound accounting for 1.0% by weight of the electrolyte solution, and stir evenly to obtain the lithium ion battery electrolyte solution of Example 2.

[0030] All the other steps are the same as in Example 1.

Embodiment 3

[0032] Electrolyte preparation: In an argon-filled glove box (moisture 6 Electrolyte, then add ethyl-bis(trimethylsilyl) phosphite compound accounting for 2.0% by weight of the electrolyte, stir evenly to obtain the lithium ion battery electrolyte of Example 3.

[0033] All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com