Thermodynamic calculation method for optimizing high-temperature brazing process of high-nitrogen steel

A technology of brazing process and calculation method, which is applied in the thermodynamic calculation field of optimizing the high-temperature brazing process of high-nitrogen steel, and can solve problems affecting pitting corrosion resistance and intergranular corrosion performance, reducing material plasticity and toughness, and affecting material properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0035] Specific implementation mode one: a kind of thermodynamic calculation method of optimizing high-nitrogen steel high-temperature brazing process of this embodiment is carried out according to the following steps:

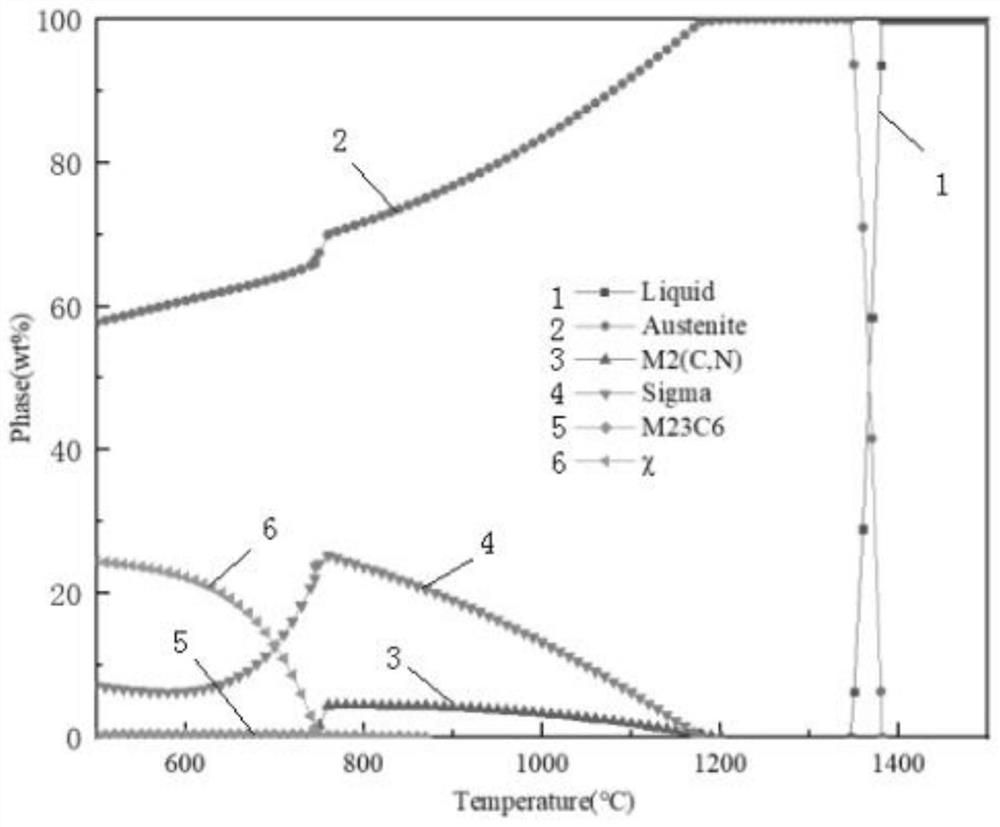

[0036] Step 1: Use the thermodynamic calculation software Jmat Pro to calculate the equilibrium phase diagram of the high-nitrogen steel precipitates based on the CALPHAD calculation method, thereby obtaining the precipitation temperature range of the high-nitrogen steel precipitates;

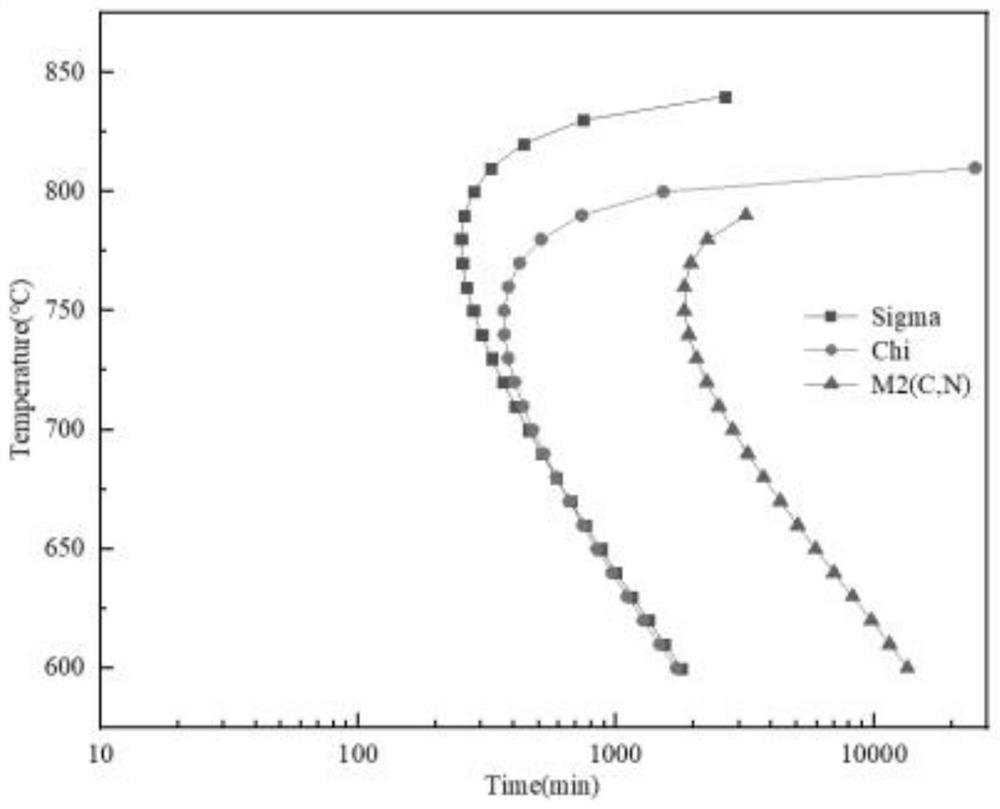

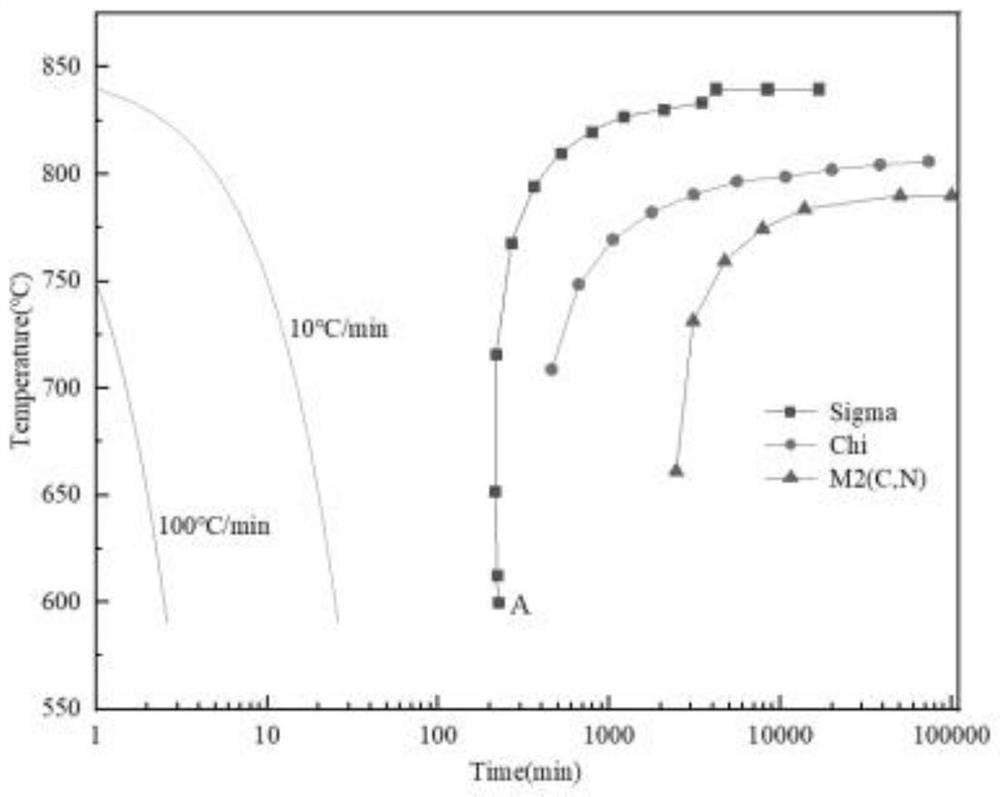

[0037] Step 2: Use the thermodynamic calculation software Jmat Pro to calculate the isothermal cooling transition curve and continuous cooling transition curve of high nitrogen steel according to the nucleation kinetic equation Johnson-Mehl-Arvami, and obtain the sensitive precipitation of high nitrogen steel precipitates from the isothermal cooling transition curve Temperature range and incubation period, the minimum cooling rate when the high-nitrogen steel precipitates start ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com