Corrosive agent for displaying subsurface crack defects of continuous casting billet and preparation method thereof

A technology of corrosive agent and steel billet, which is applied in the preparation of test samples, optical testing of flaws/defects, etc., can solve problems such as incompleteness, and achieve the effects of simple operation, energy saving, and fast inspection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

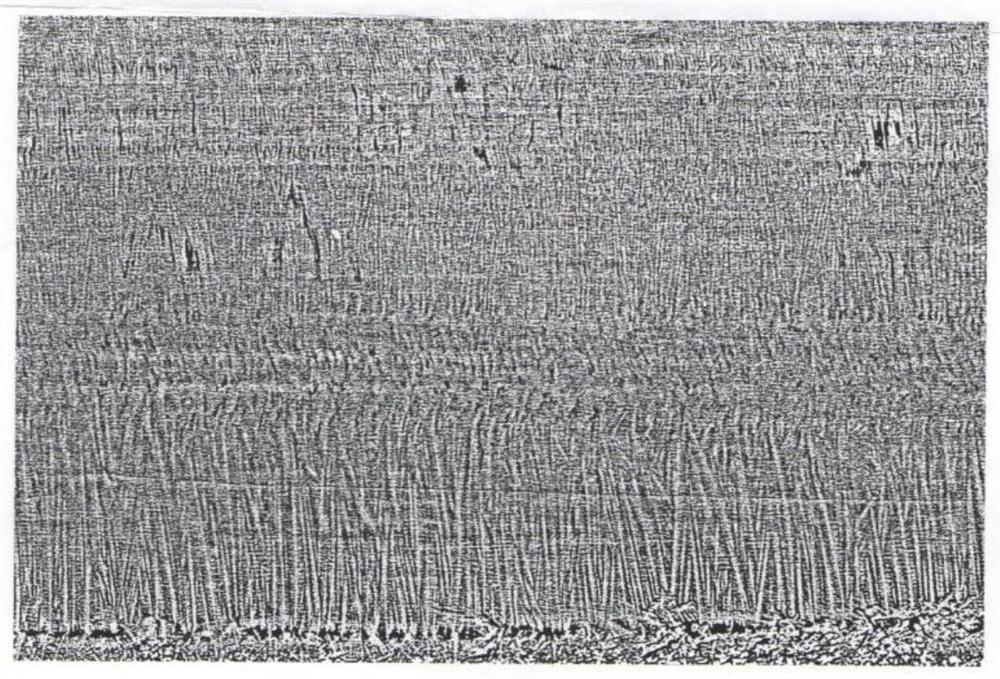

[0032] It is used to show the low carbon steel continuous casting slab containing C 0.12wt%; Si 0.11wt%; Mn 0.34wt%; P 0.011wt%; S0.0051wt%; Cr 0.003wt%; Subcutaneous crack defect morphology.

[0033] 1) Preparation of corrosive liquid:

[0034]Get 6 grams of stannous chloride solid medicament and place in a glass container, add 1600 milliliters of distilled water, the stannous chloride solid medicament is dissolved. Take 105 milliliters of absolute ethanol and add it to the stannous chloride aqueous solution, stir evenly, add 10 milliliters of nitric acid to the above solution, stir evenly, then add 53 milliliters of hydrochloric acid, and shake evenly. Stand for 2 hours as mother liquor.

[0035] Get an equal amount of copper chloride and magnesium chloride solid medicament 0.2 grams and add it to the mother liquor, observe the color change of the medicament while stirring, then take the same amount of the two, take 0.1 gram as the unit, continuously increase the amount ad...

Embodiment 2

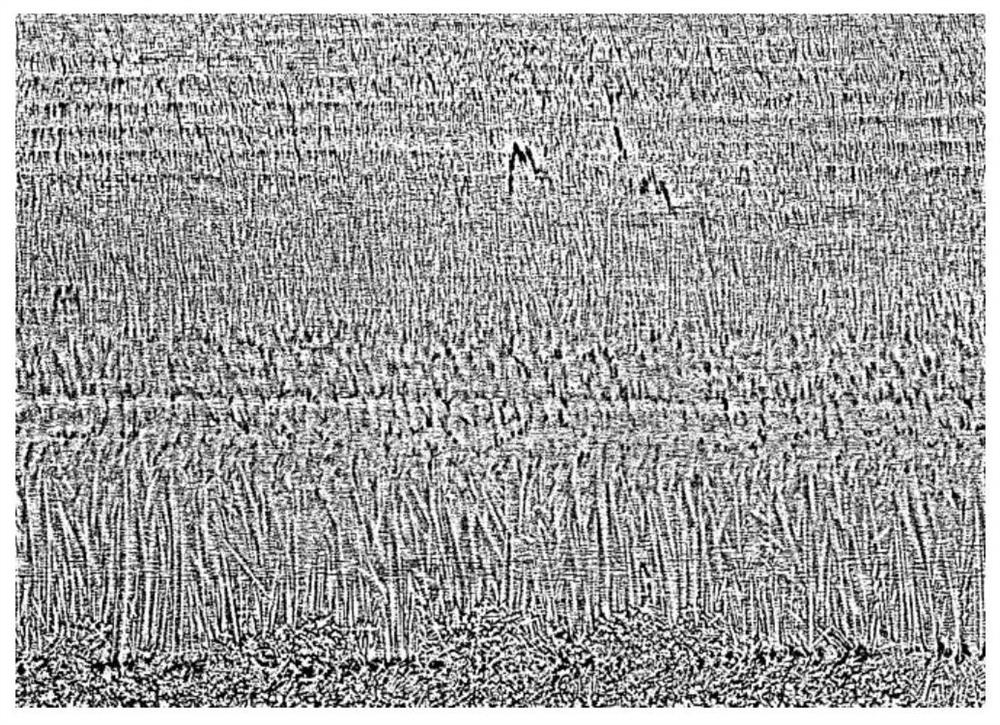

[0042] It is used to show the defect morphology of subcutaneous bubbles in continuous casting slabs containing 0.14wt% C; 0.26wt% Si; 0.21wt% Mn; 0.104wt% P; 0.003wt% S; the balance is Fe.

[0043] 1) Preparation of corrosion liquid:

[0044] Get 7 grams of stannous chloride solid medicament and place in a glass container, add 1800 milliliters of distilled water, the stannous chloride solid medicament is dissolved. Take 115 milliliters of absolute ethanol and add it to the tin protochloride aqueous solution, stir evenly, add 11 milliliters of nitric acid into the above solution, stir evenly, then add 56 milliliters of hydrochloric acid, and shake evenly. Stand for 2 hours as mother liquor.

[0045] Get equal amount of cupric chloride, magnesium chloride 0.4 gram and add in the mother liquor respectively, observe the change of medicament color while stirring, then get both equivalent values, take 0.1 gram as unit, constantly increase the amount of cupric chloride, magnesium ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com