Method for preparing high-purity ruthenium target EBSD samples

A kind of sample and high-purity technology, which is applied in the field of preparing high-purity ruthenium target EBSD samples, can solve the problems of false test results, high melting point, complexity, etc., and achieve the effect of not being easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

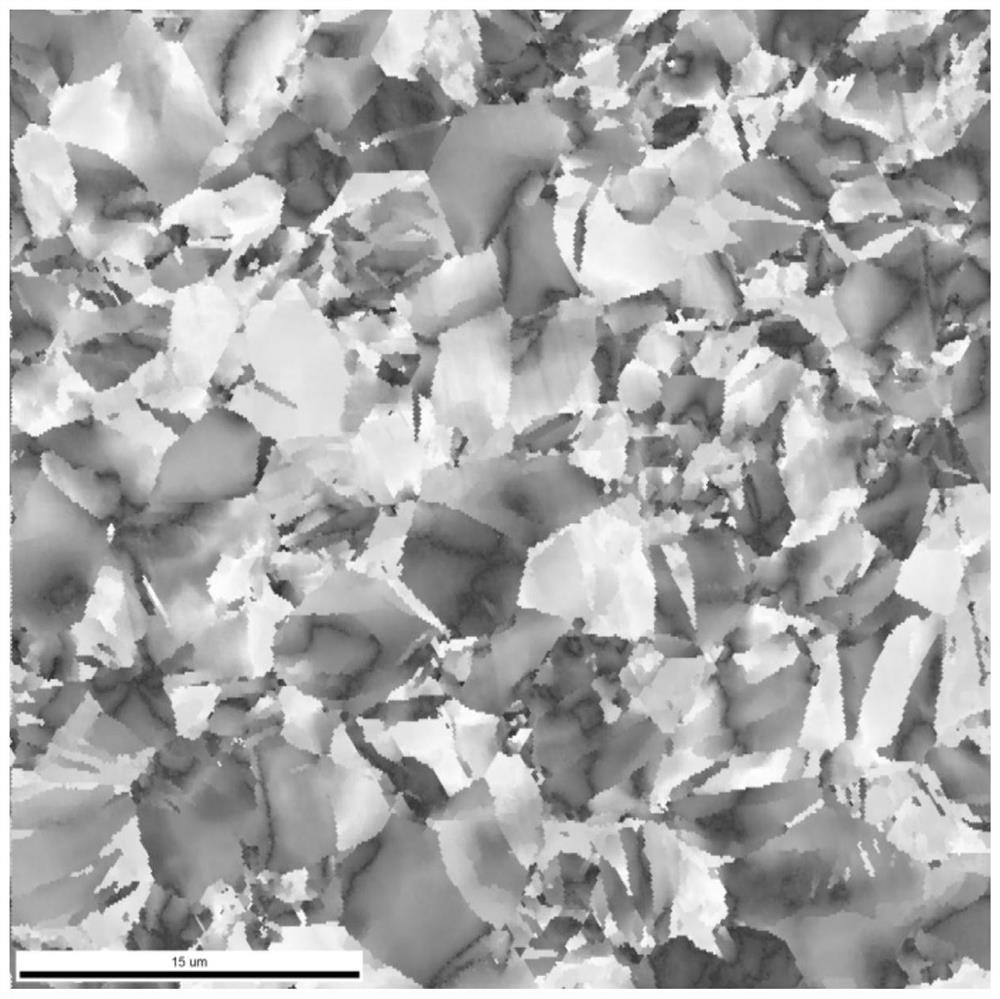

Image

Examples

Embodiment 1

[0034] A method for preparing a high-purity ruthenium target EBSD sample, the specific steps of the preparation method are:

[0035] Step 1: cutting the high-purity ruthenium target wire obtained by hot-pressing sintering into a sample to be tested, and the size of the sample is 1cm×1cm×1cm.

[0036] Step 2. Mechanically polish the sample to be tested as described in step 1, and polish the sample on water sandpaper of 150 mesh, 500 mesh, 800 mesh, 1500 mesh, and 2000 mesh in turn, and each sandpaper is ground to the sample Rinse the sample with clean water when the scratches on the surface are uniform and in one direction, and rotate the sample by 90°. Change to a sandpaper for fine grinding, and finally rinse with clean water.

[0037] Step 3. Put the rinsed sample on a polishing machine equipped with polishing flannelette for polishing, add W2.5 and W1.0 polishing pastes in sequence, and polish until the last scratch disappears. The total polishing time is 4 minutes. The p...

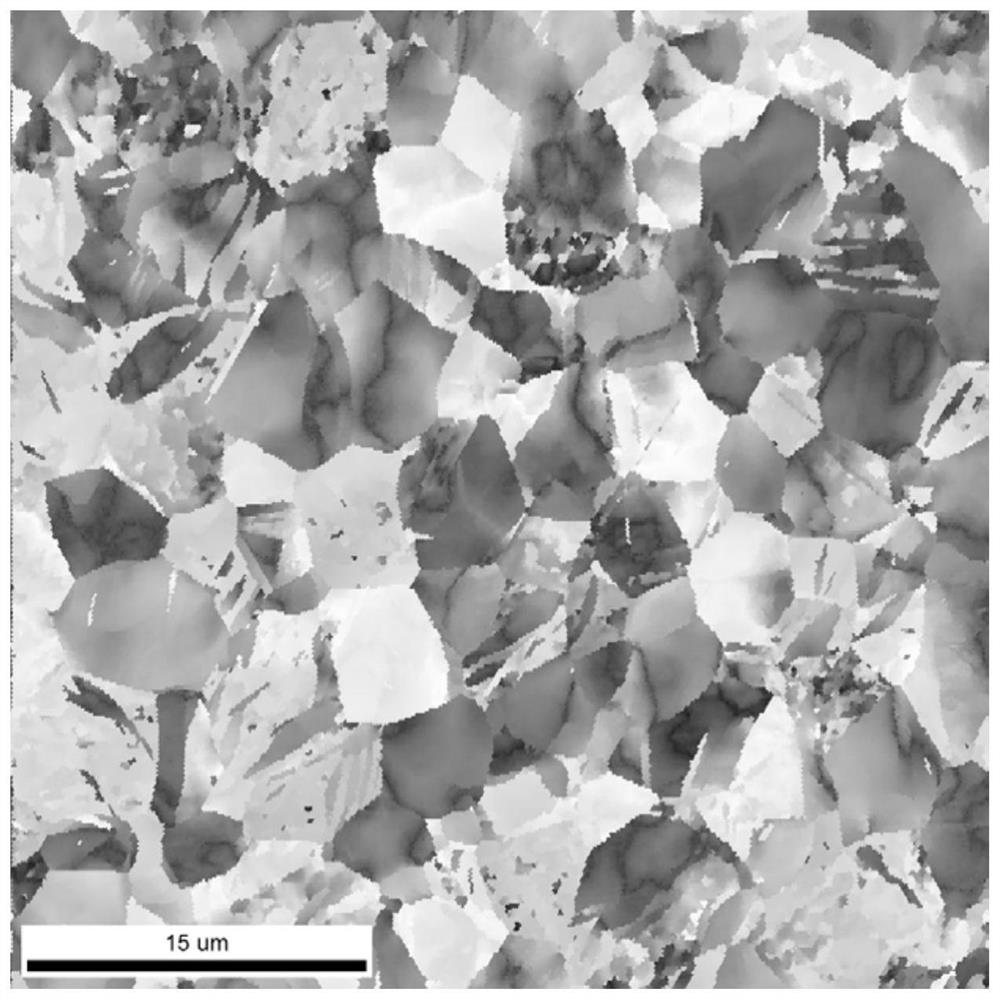

Embodiment 2

[0041] A method for preparing a high-purity ruthenium target EBSD sample, the specific steps of the preparation method are:

[0042]Step 1: cutting the high-purity ruthenium target wire obtained by hot-pressing sintering into a sample to be tested, and the size of the sample is 1cm×1cm×1cm.

[0043] Step 2. Mechanically polish the sample to be tested as described in step 1, and polish the sample on water sandpaper of 150 mesh, 500 mesh, 800 mesh, 1500 mesh, and 2000 mesh in turn, and each sandpaper is ground to the sample Rinse the sample with clean water when the scratches on the surface are uniform and in one direction, rotate the sample 90°, change to a sandpaper for fine grinding, and finally rinse with clean water.

[0044] Step 3. Put the rinsed sample on a polishing machine equipped with a polishing cloth, add W2.5 and W1.0 polishing pastes in sequence, and polish until the last scratch disappears. The total polishing time is 3.5 minutes. The polished sample was rinsed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com