Large-numerical-aperture laser lens imaging inspection system

A numerical aperture and laser lens technology, applied in the field of optical inspection, can solve problems such as irregular shape, chromatic aberration interference, and uncertain quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

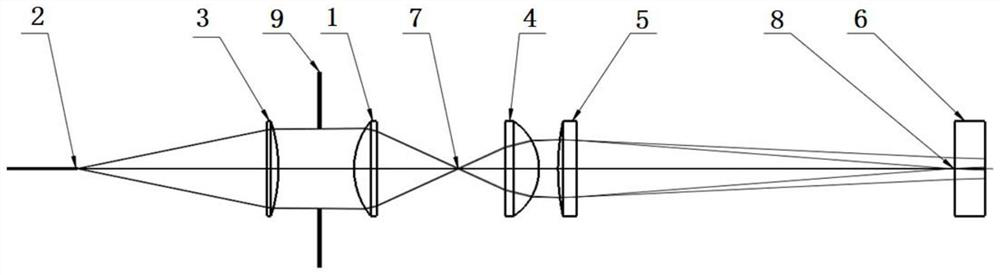

[0015] Such as figure 1 As shown, a large numerical aperture laser lens imaging inspection system is mainly composed of a laser lens to be tested 1, a single-mode monochromatic light source 2, an optical fiber collimator 3, a standard objective lens 4, a standard tube lens 5, and an area array CCD element 6 .

[0016] Single-mode monochromatic light source 2, fiber optic collimator 3, standard objective lens 4, standard tube lens 5 and area array CCD element 6 are set at intervals in sequence, the laser lens to be tested 1, single-mode monochromatic light source 2, fiber optic collimator 3, Standard objective lens 4, standard tube lens 5, and area array CCD element 6 are located on the same optical axis.

[0017] The single-mode monochromatic light source 2 and the fiber collimator 3 constitute a parallel light system. After the single-mode monochromat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core diameter | aaaaa | aaaaa |

| Effective focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com