High-speed railway large-diameter shield tunnel overhead line system channel construction method

A technology for shield tunneling and high-speed railways. It is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as template warping, quality impact, and overall channel strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

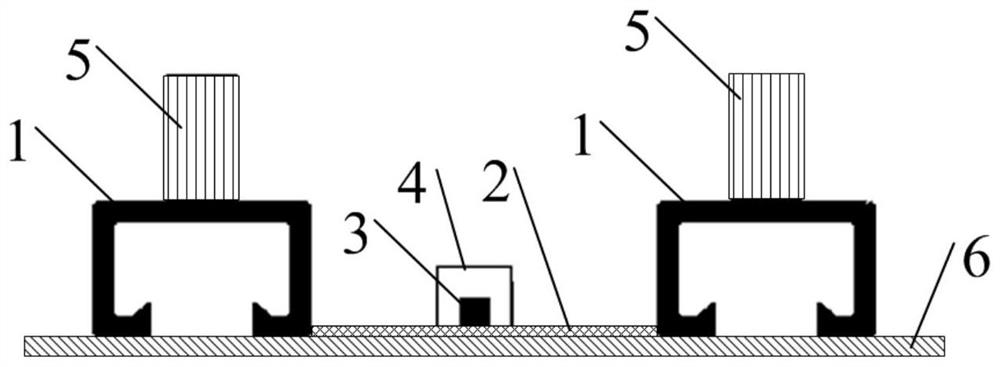

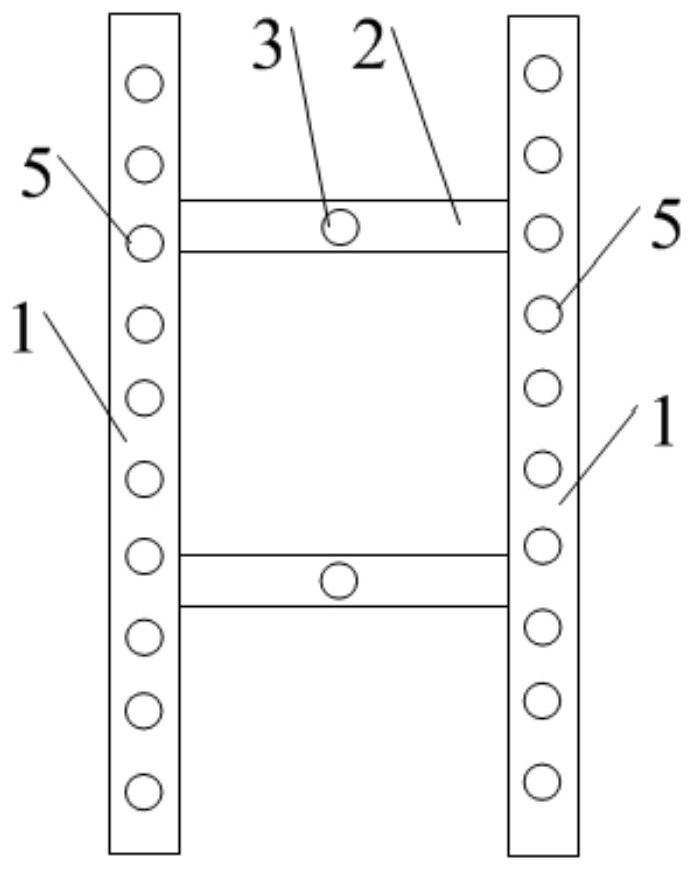

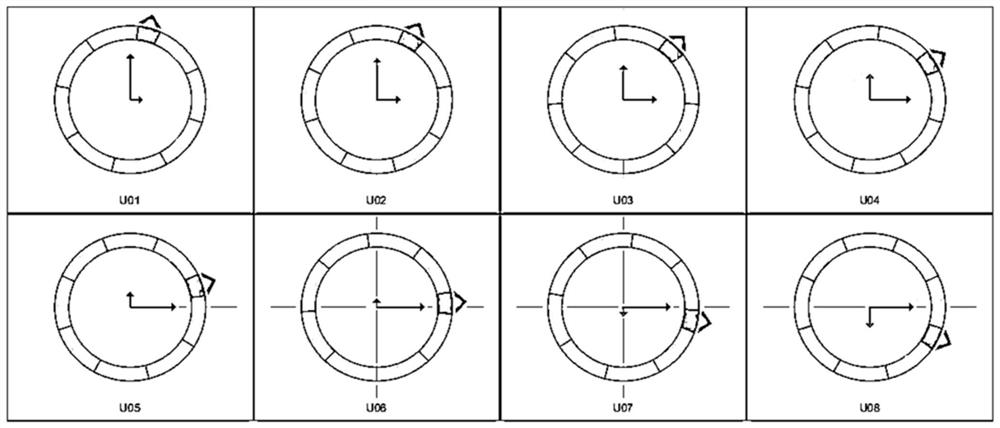

[0058] The invention provides a method for constructing catenary channels of large-diameter shield tunnels for high-speed railways. The method involved in the invention is a construction method for digging tunnels underground. Using the subway shield machine to excavate underground, while preventing the soft ground excavation surface from collapsing or maintaining the stability of the excavation surface, tunnel excavation and lining operations can be safely carried out inside the machine. The construction process needs to excavate a shaft or a foundation pit at one end of a certain section of the tunnel, hoist the subway shield machine into the installation, and the subway shield machine starts to excavate from the wall opening of the shaft or foundation pit and advances along the designed hole line until To reach the end of another shaft or tunnel in the hole line.

[0059] Among them, such as Figures 1 to 7 As shown, the methods include:

[0060] Make channel mechanism; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com