Circulating pressure-maintaining multi-turn grouting method for dam seepage-proofing reinforcement

An environmental protection and dam technology, applied in drinking water installations, water supply installations, buildings, etc., can solve problems such as poor anti-seepage reinforcement effect, difficulty in determining the completion of grouting, and insufficient slurry diffusion distance, so as to reduce subjectivity and experience. , Shorten the construction period, good consolidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A cyclic pressure-holding multi-round grouting method for anti-seepage reinforcement of embankments, comprising the following steps:

[0040] A. Determine the location of the permeable layer that needs to be disposed of. The detection methods include dipole dipole detection of high-density electrical method, Wenner type of high-density electrical method, Shi Lun Bell type, transient electromagnetic method, ground penetrating radar, geological drilling Hole and pressure water tests;

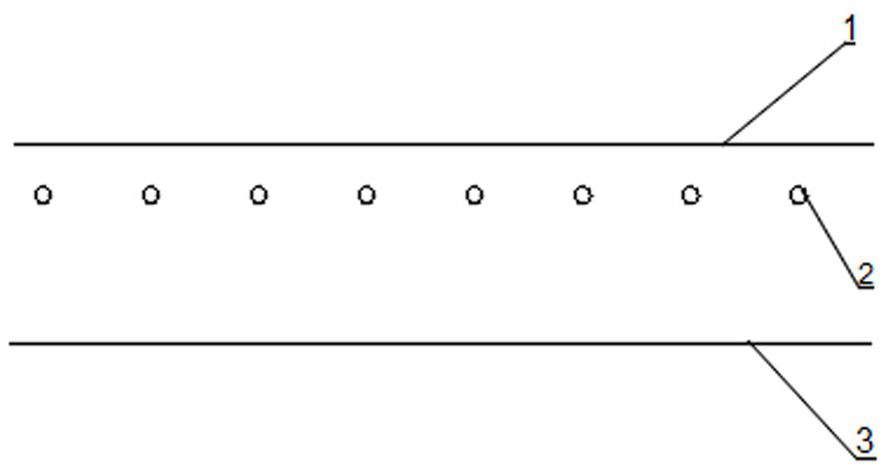

[0041] B. In the form of curtain grouting, holes are arranged on the top of the dam close to the water surface, and the schematic diagram of the horizontal holes is shown in figure 1 As shown, then drill the grouting hole with a drilling rig, and the side view of the drilling hole is shown in figure 2 as shown, Figure 1~2Mark 1 is the water-facing surface, 2 is the grouting hole, and 3 is the back-water surface; the curtain grouting is carried out by arranging one or two rows of plum-bl...

Embodiment 2

[0047] This embodiment is a model test:

[0048] Excavate a cuboid model tank with a length of 4m, a width of 2m and a depth of 2m at a construction site, and then backfill the model tank with silt layer by layer. fill up. Then drill the grouting hole at the top layer, lower the grouting pipe, and finally carry out the grouting. The grouting method and the grouting material are the same as in Example 1. Soil density setting 1.5g / cm 3 , the porosity is 49%, the grouting pressure is 0.5MPa, and the grouting amount of the permeable material is 200Kg. In this example, the DCP penetration test is used to test the bearing capacity of the consolidated body after the grouting before and after the grouting. The DCP test points and the model test plan are shown in Figure 6 As shown, the test results are as follows Figure 7 As shown in , the consolidated body is excavated after grouting, and samples are taken to test the compressive strength and impermeability of the consolidated b...

Embodiment 3

[0057] An embankment project is located on the north bank of the earth pond in the southeast of a certain county in Jiangxi Province. There are problems: the filling is not compact, the construction quality is poor, and the dam foundation and abutment are not completely drained, which leads to serious leakage of some embankment foundations, bubble springs, piping There are many; there is no hard slope protection on the facing surface of the embankment or the slope protection is seriously damaged, the anti-scourability is poor, and it is severely scoured by wind waves and currents; some dike sections have steep banks facing the current, and there are no bank fixing measures or the bank fixing measures cannot meet the requirements; Some buildings have been in operation for many years, and the equipment is seriously damaged due to aging and cannot operate normally.

[0058] Before the grouting reinforcement, the high-density electrical detection of the hidden dangers of the embank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com