Titanium alloy segmented vacuum rapid nitriding method and device

A vacuum fast, titanium alloy technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of high brittleness, long processing time, and thin permeation layer, so as to improve performance and guarantee The effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) After polishing and cleaning the TC4 titanium alloy sample, put it into the reaction tank, and pass high-purity nitrogen gas with a purity ≥ 99.99% into the reaction tank until all the air in the tank is exhausted;

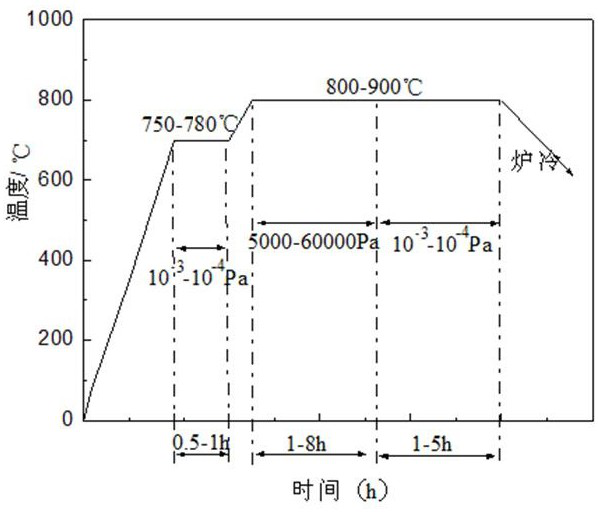

[0039] 2) Press figure 1 Process curve shown, the reaction tank is evacuated to 10 -3 Pa, then the temperature of the reaction tank was raised to 780°C, and kept for 0.5h;

[0040] 3) Press figure 1According to the process curve shown, the high-purity nitrogen gas is introduced into the reaction tank until the pressure in the tank reaches 60000Pa, then the temperature of the reaction tank is raised to 800°C, and the temperature is kept; the nitrogen is extracted until the pressure in the tank is reduced to 5000Pa, and the temperature is kept; react again Inject high-purity nitrogen into the tank until the pressure in the tank reaches 60,000Pa, and keep warm; carry out 8 cycles of nitriding according to the pressure alternating cycle of high pressure-lo...

Embodiment 2

[0043] Each step is with embodiment 1, wherein:

[0044] In step 2), the vacuum degree of the reaction tank is 10 -4 Pa, the temperature is 750°C, and the holding time is 1h;

[0045] In step 3), the high pressure in the tank is 30000Pa, the nitriding temperature is 900°C, the low pressure in the tank is 15000Pa, the nitriding cycle is performed twice, and the total time of the nitriding cycle is 1h; the high-pressure holding time of each cycle nitriding, The low pressure holding time is 15min.

[0046] In step 4), the vacuum diffused for 1h and the vacuum degree was 10 -4 Pa.

Embodiment 3

[0048] Each step is with embodiment 1, wherein:

[0049] In step 2), the vacuum degree of the reaction tank is 10 -4 Pa, the temperature is 765°C, and the holding time is 0.7h;

[0050] In step 3), the high pressure in the tank is 50000Pa, the nitriding temperature is 850°C, the low pressure in the tank is 10000Pa, the nitriding cycle is 9 times, and the total time of the nitriding cycle is 6h; the high-pressure holding time of each cycle nitriding, The low pressure holding time is 20min.

[0051] In step 4), the vacuum diffuses for 4 hours and the vacuum degree is 10 -3 Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com