Alloy material of valve and valve

A technology of alloy materials and valves, which is applied in the direction of lifting valves, mechanical equipment, valve devices, etc., and can solve the problems of difficult oxidation resistance and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment bar and solid solution aging treatment

[0033] C: 0.50(wt)%; Si: 0.14(wt)%;

[0034] Mn: 9.20(wt)%; P: 0.024;

[0035] S: 0.004(wt)%; Cr: 26.43(wt)%;

[0036] Ni: 3.91(wt)%; N: 0.59(wt)%;

[0037] W: 0.97(wt)%; Nb: 2.24(wt)%; and

[0038] The balance is Fe and unavoidable impurities.

[0039] Next, perform solution aging treatment on the obtained rods: solution treatment at about 1180°C for about half an hour, then water-cooled to room temperature; then aging treatment at about 780°C for about 1 hour, and finally air-cooled to room temperature.

[0040] Comparative example bars and solution aging treatment

[0041] The bars of the comparative example were prepared according to the process steps of the bars of the above examples. Compared with the above examples, only the chromium content ratio was adjusted to 21% in the comparative example, and the others remained unchanged.

[0042] Related performance comparison

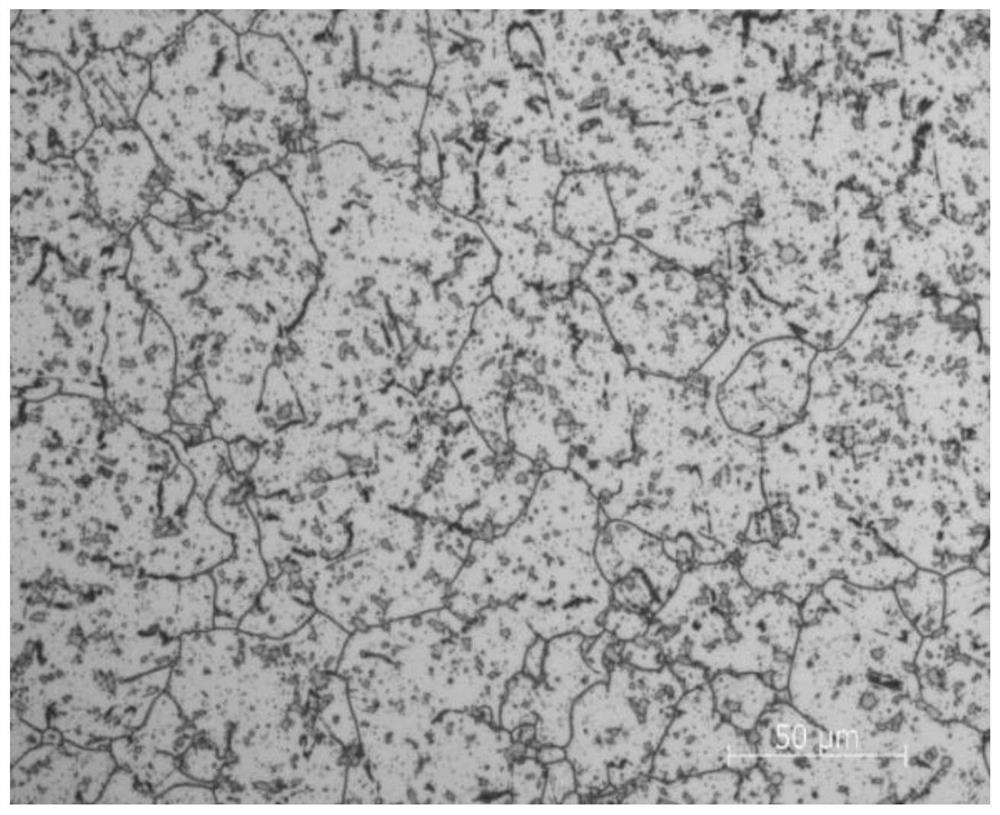

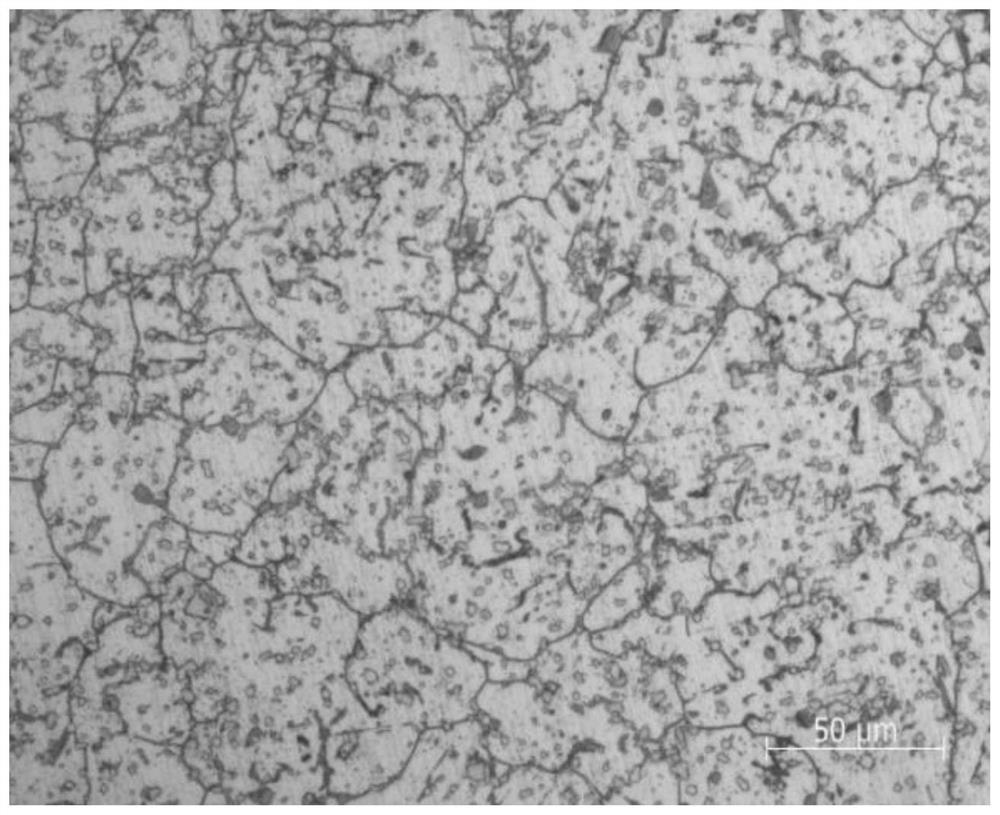

[0043] figure 1 and figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com