High-melting-point Kelvin structure lattice metal as well as preparation method and application thereof

A high-melting-point metal and high-melting-point technology, applied in metal processing equipment, manufacturing tools, casting molding equipment, etc., can solve the problems of narrow application range of lattice metal, insufficient strength and temperature resistance, etc., to ensure high temperature strength and release The effect of eliminating, high strength, and expanding the application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment is to design and prepare a Kelvin structure lattice metal with a porosity of 58% and 304 stainless steel as a matrix;

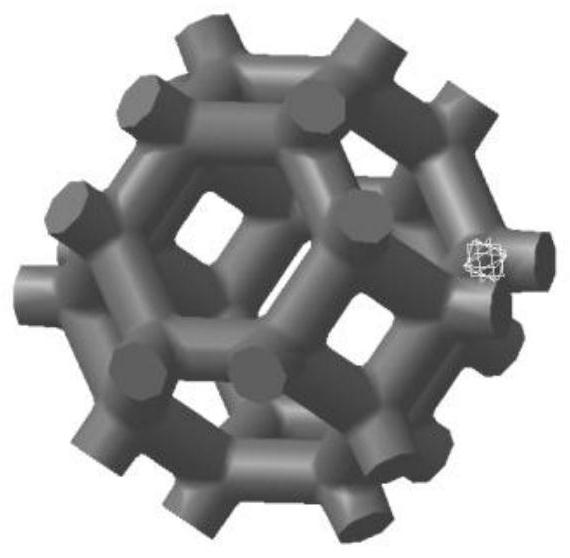

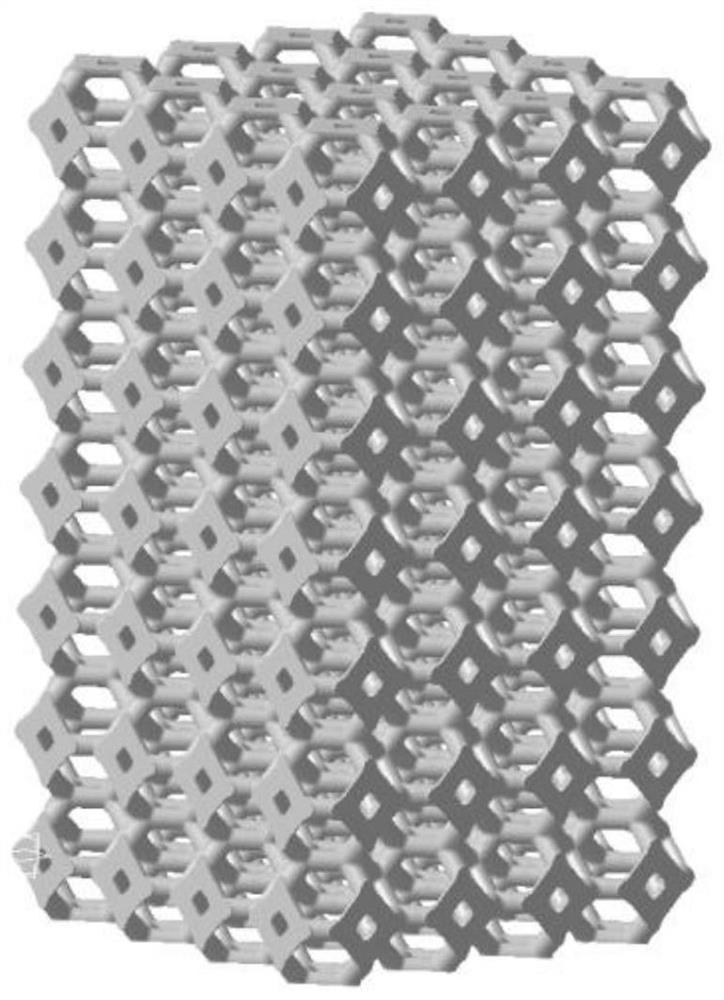

[0037] Such as Figure 1a As shown, it is a design model of a Kelvin structure lattice metal unit. The Kelvin structure lattice metal unit adopts a three-dimensional modeling software for adaptive design of a casting process, and a three-dimensional Kelvin structure lattice metal unit 100 with a prism 101 as a main body is designed. Its prism 101 diameter is 2mm, and prism 101 length is 2.4mm, and prism aspect ratio is 1.2, and Kelvin structure lattice metal three-dimensional design model, as Figure 1b As shown, the outer contour size of the high-melting point Kelvin structure lattice metal design model is 48×27×27 mm, and the porosity is 58%.

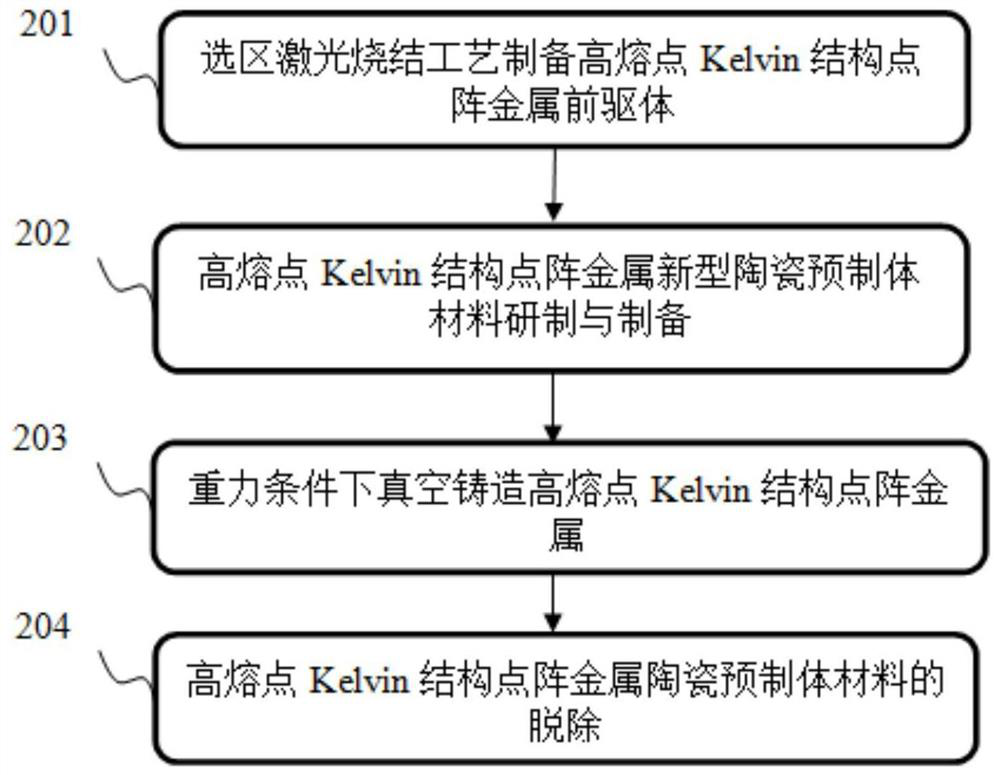

[0038] Such as figure 2 As shown, it is a flow chart of the preparation process of high melting point Kelvin structure lattice metal, which uses indirect 3D printing combined with precision c...

Embodiment 2

[0046] This embodiment is to design and prepare a Kelvin structure lattice metal with 304 stainless steel as the matrix with a porosity of 82%;

[0047] The Kelvin structure lattice metal unit adopts three-dimensional modeling software to carry out adaptive design of the casting process, and designs a three-dimensional Kelvin structure lattice metal unit 100 with prism 101 as the main body. The diameter of the prism 101 is 3 mm, and the length of the prism 101 is 6 mm. The aspect ratio of a prism is 2. The outer contour size of the three-dimensional design model of the high melting point Kelvin structure lattice metal is 119×68×68 mm, and the porosity is 82%.

[0048] Such as figure 2 As shown, it is a flow chart of the preparation process of high melting point Kelvin structure lattice metal, which uses indirect 3D printing combined with precision casting process to prepare 304 stainless steel as the matrix Kelvin structure lattice metal, including the following steps:

[0...

Embodiment 3

[0056] This embodiment is to design and prepare a Kelvin structure lattice metal with 304 stainless steel as the matrix with a porosity of 88%;

[0057] The Kelvin structure lattice metal unit adopts three-dimensional modeling software to carry out adaptive design of the casting process, and designs a three-dimensional Kelvin structure lattice metal unit 100 with a prism 101 as the main body. The diameter of the prism 101 is 10 mm, and the length of the prism 101 is 30 mm. The aspect ratio of the prism is 3.0. The outer contour size of the three-dimensional design model of the high-melting point Kelvin structure lattice metal is 594×339×339mm, and the porosity is 92%.

[0058] Such as figure 2 As shown, it is a flow chart of the preparation process of high melting point Kelvin structure lattice metal, which uses indirect 3D printing combined with precision casting process to prepare 304 stainless steel as the matrix Kelvin structure lattice metal, including the following ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com