Gypsum shell low in retained strength and preparing method of gypsum shell

A residual strength, gypsum mold technology, applied in casting molding equipment, molds, cores, etc., can solve the problems of imperfect cleaning and high labor intensity of shell cleaning, reduce residual strength, improve production speed and economic benefits, The effect of low residual strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

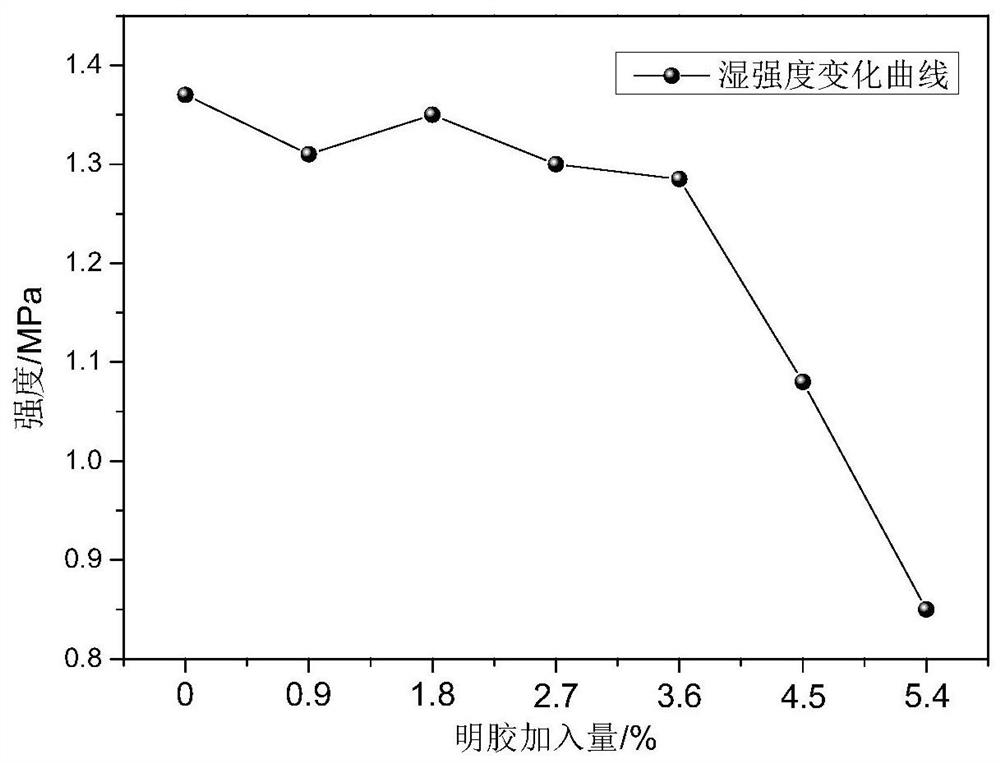

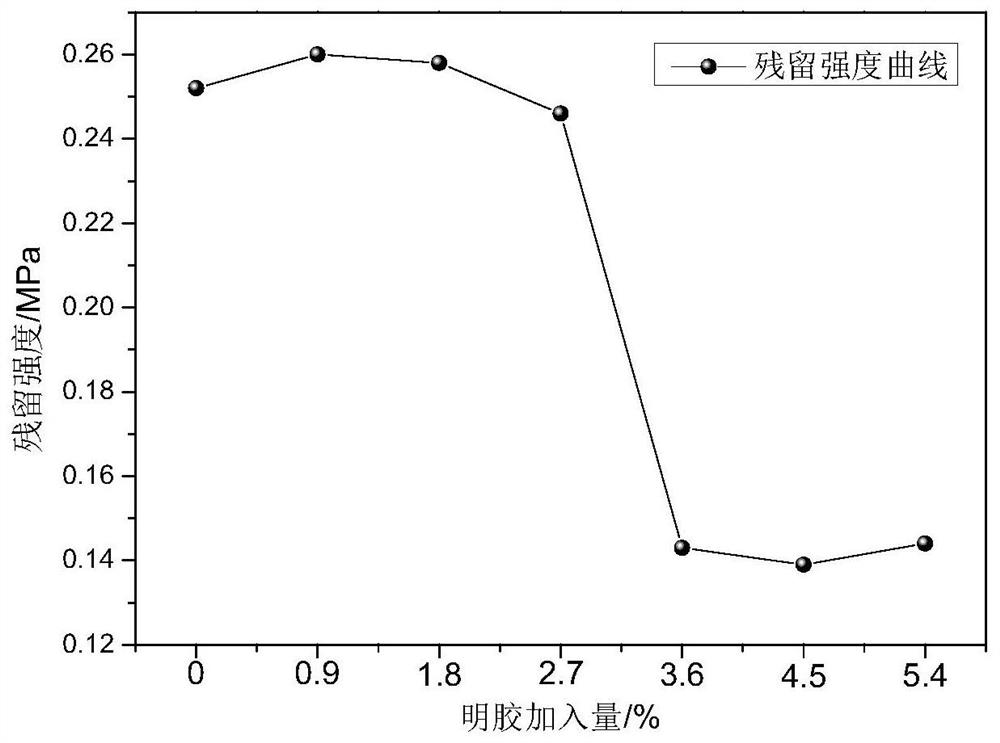

Examples

Embodiment 1-6 and comparative example 1

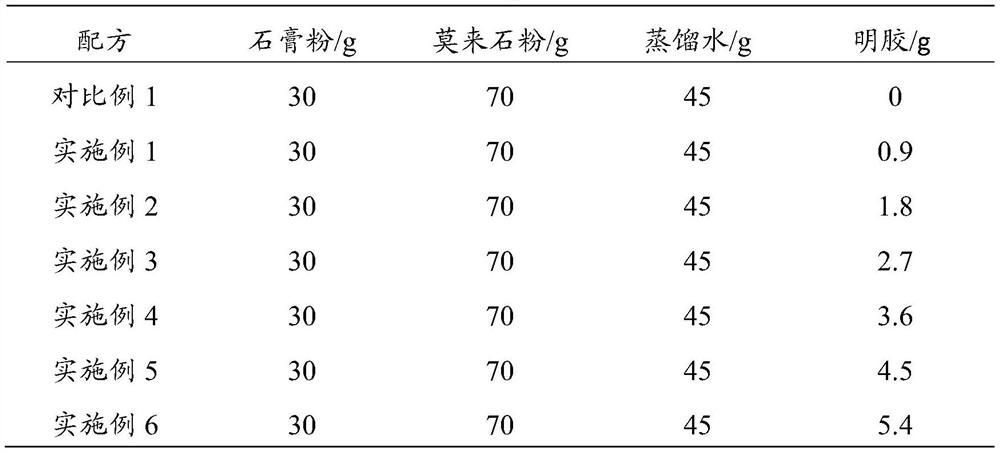

[0025] (1) Weigh each raw material according to Table 1:

[0026] Table 1

[0027]

[0028] (2) Put the weighed gypsum powder and mullite powder into a clean container and stir well to make them mix evenly (there is no obvious color difference after mixing evenly, and the colors are consistent);

[0029] (3) Heat the weighed distilled water to 65° C., then add the weighed gelatin into the hot distilled water for dissolving, and obtain a transparent solution after the gelatin is dissolved and mixed evenly, and store for future use.

[0030] (4) Add the mixed powder of gypsum powder and mullite powder obtained in step (2) to the transparent solution obtained in step (3), and stir at a speed of 250r / min for 2min, so that the mixed slurry is stirred evenly until no precipitation;

[0031] (5) The slurry obtained in step (4) is poured into the mould, so that the slurry is filled with the inner cavity of the mould, and during the pouring process, the slurry will be dropped from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com