Method for preparing high-elongation cast-rolled Al-Mn series aluminum alloy slab

A technology of high elongation and aluminum alloy, which is applied in the field of preparing high elongation cast-rolled Al-Mn series aluminum alloy slabs, can solve the problems of longer process flow and increased time consumption, and achieve reduction of process flow, slight segregation, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Melting

[0062] Smelting is carried out according to the mass percentage of components: Si: 0.5%, Mn: 1.2%, and the balance is Al; the calculated corresponding mass of industrial pure aluminum ingots, aluminum-manganese intermediate alloys, and aluminum-silicon intermediate alloys are sequentially added to the melting furnace In the process, the melting temperature is 720°C to obtain molten aluminum for casting and rolling, adding 0.1% TiB 2 -TiC particles, keep warm for 5 minutes, then add slag remover, remove slag and degas;

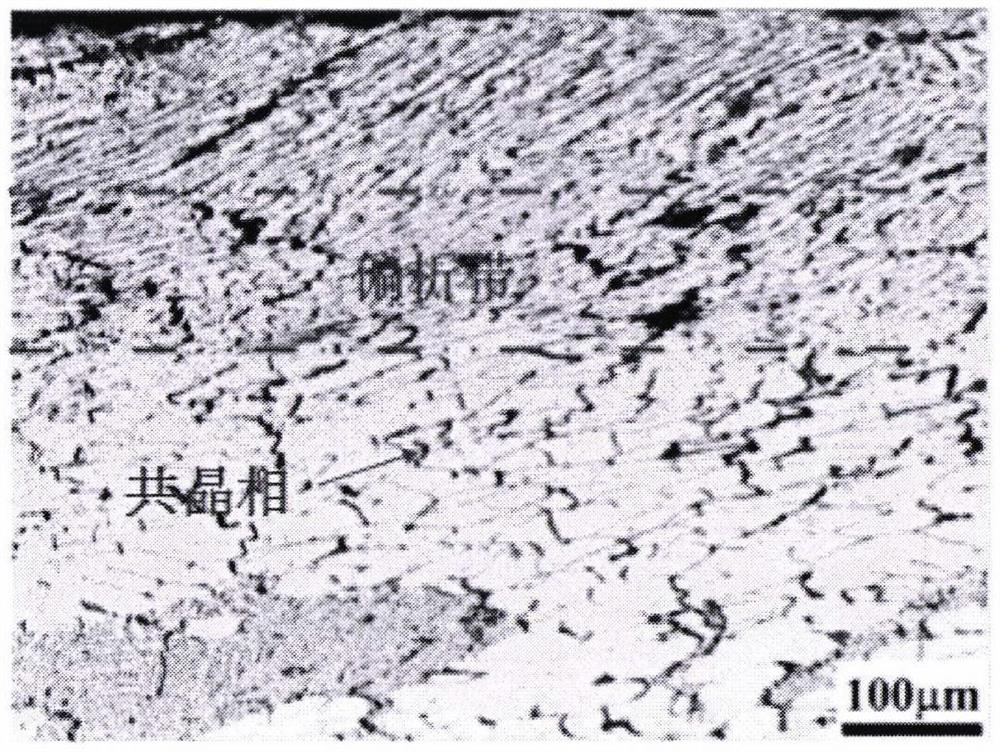

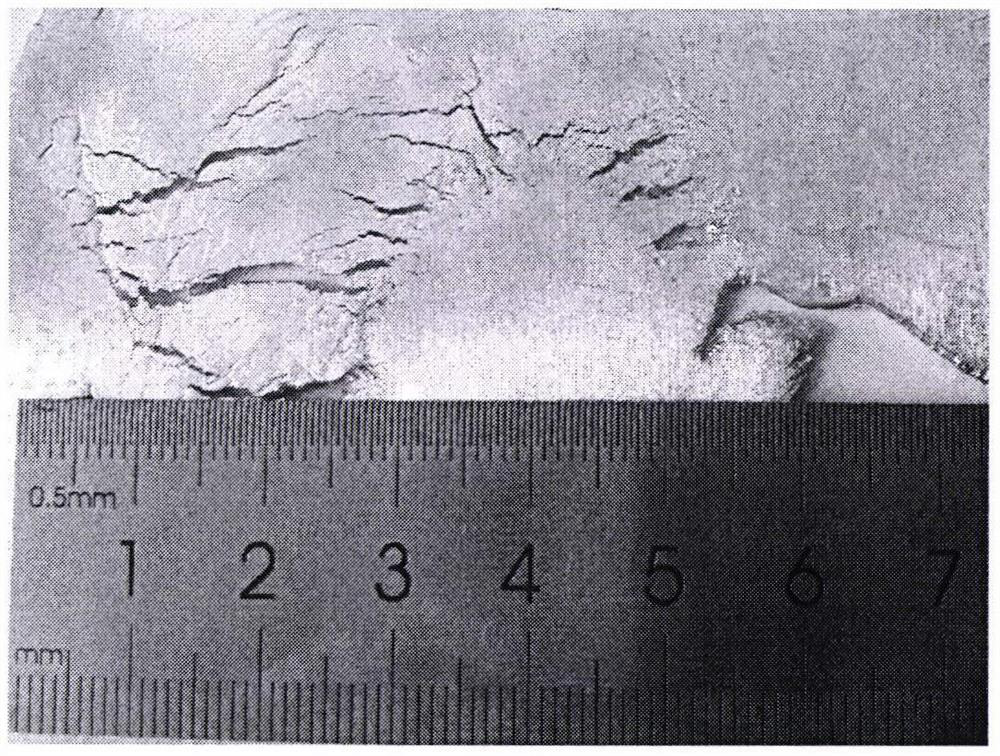

[0063] (2) Casting and rolling

[0064] The obtained molten aluminum is subjected to twin-roll vertical casting and rolling. The casting temperature is 700°C, the casting and rolling speed is 12m / min, the roll gap width is 0.3mm, and the rolls are copper leather rolls, which are cooled by circulating water to obtain the thickness. 1mm cast-rolled plate, trimming after cooling;

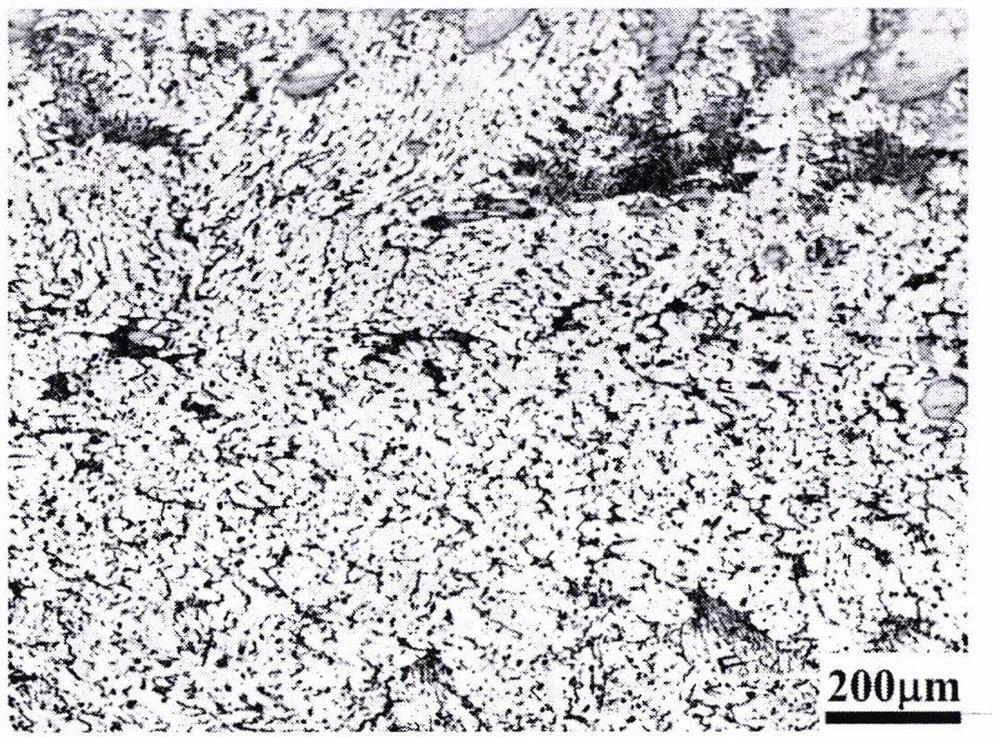

[0065] (3) rolling deformation

[0066] The obtained cast-...

Embodiment 2

[0072] (1) Melting

[0073] Smelting is carried out according to the mass percentage of components: Si: 0.5%, Mn: 1.2%, and the balance is Al; the calculated corresponding mass of industrial pure aluminum ingots, aluminum-manganese intermediate alloys, and aluminum-silicon intermediate alloys are sequentially added to the melting furnace In the process, the melting temperature is 750°C, and the molten liquid for casting and rolling is obtained, and 0.5% TiB is added 2 -TiC particles, keep warm for 15 minutes, then add slag remover, remove slag and degas;

[0074] (2) Casting and rolling

[0075] The obtained molten aluminum is subjected to twin-roll vertical casting and rolling, the casting and rolling pouring temperature is 680°C, the casting and rolling speed is 5m / min, the roll gap width is 2.5mm, and the rolls are copper leather rolls, which are cooled by circulating water to obtain the thickness It is a 3mm cast-rolled plate, which is trimmed after cooling;

[0076] (3...

Embodiment 3

[0083] (1) Melting

[0084] Smelting is carried out according to the mass percentage of components: Si: 0.5%, Mn: 1.2%, and the balance is Al; the calculated corresponding mass of industrial pure aluminum ingots, aluminum-manganese intermediate alloys, and aluminum-silicon intermediate alloys are sequentially added to the melting furnace In the process, the melting temperature is 750°C to obtain molten liquid for casting and rolling, and 0.9% TiB is added 2 -TiC particles, keep warm for 30 minutes, then add slag remover, remove slag and degas;

[0085] (2) Casting and rolling

[0086] The obtained molten aluminum is subjected to double-roller vertical casting and rolling. The casting temperature is 670°C, the casting-rolling speed is 8m / min, the roll gap width is 3mm, and the rolls are copper leather rolls, which are cooled by circulating water to obtain a thickness of 4mm cast-rolled plate, trimming after cooling;

[0087] (3) rolling deformation

[0088] The obtained cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com