Waterborne anticorrosive coating as well as preparation method and application thereof

An anti-corrosion coating, water-based technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of large application market of light anti-corrosion coatings, loss of gloss, affecting aesthetics and service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

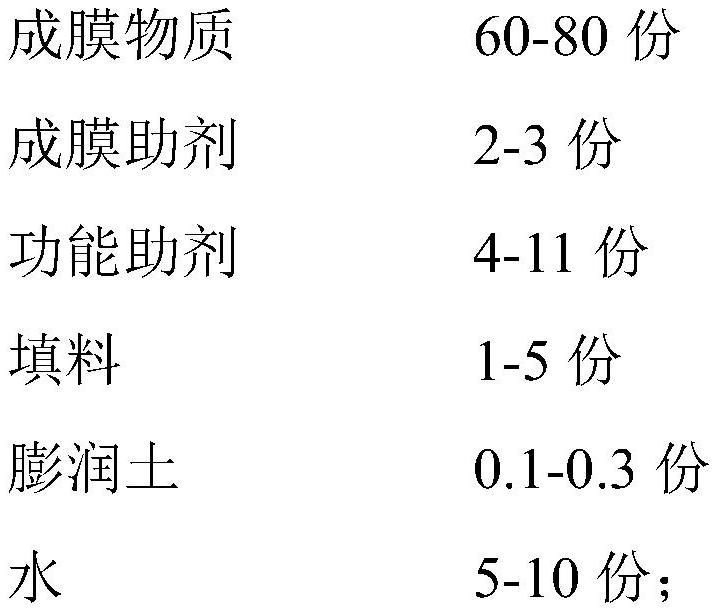

[0054] The present invention also provides a preparation method of the above-mentioned water-based anticorrosion coating, which includes the following steps: mixing the water, bentonite, film-forming substance, film-forming aid, filler and functional auxiliary to prepare the water-based anti-corrosion coating.

[0055] Further, the following steps are included:

[0056] S101: Put water, dispersant, wetting agent, bentonite, pH adjuster, 1 / 3~1 / 2 defoamer, rutile titanium dioxide, anti-rust pigment, filler at a speed of 1500r / min-2000r / min Disperse under the condition that makes the first slurry;

[0057] S102: Add film-forming substances, anti-rust pigments, film-forming aids, anti-rust aids, hydrophobic aids, thickeners, anti-corrosion and anti-fungal agents, and the remaining amount of defoaming agents to the first slurry, and Disperse evenly under the condition of 400r / min-600r / min.

[0058] By first making the powder into a slurry and then mixing it with other components ...

Embodiment 1

[0062] Formula (by weight): 5 parts of deionized water, 1.2 parts of dispersant (SN 5040), 0.5 parts of wetting agent (LFH), 0.2 parts of bentonite (50S), 0.2 parts of pH regulator (Vantex-T), 0.2 parts of defoamer (BYK-024), 20 parts of rutile titanium dioxide (R902+), 2.0 parts of filler (mica powder), 1 part of antirust pigment (Nubirox 302), modified water-based acrylate emulsion (DSMXK-802 emulsion ) 60 parts, 28.4 parts of pigment slurry, 2.5 parts of film-forming additives, 0.5 parts of anti-rust additives (FA 179), 1 part of hydrophobic additives (wax emulsion WAX 966), 0.8 parts of thickeners, anti-corrosion and anti-fungal agents 0.8 parts, 0.2 parts of defoamer; see Table 1 for details;

[0063] Preparation:

[0064] (1) Put water, dispersant, wetting agent, bentonite, pH regulator, 1 / 3~1 / 2 defoamer, rutile titanium dioxide, antirust pigment, and filler at a speed of 1500r / min-2000r / min Disperse under the condition of min to make the first slurry;

[0065] (2) Ad...

Embodiment 2~7

[0070] The formulation raw materials and preparation method are the same as in Example 1, and the specific formulation ratios are different, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com