A kind of preparation method and application of bimetallic mof based on mof-808

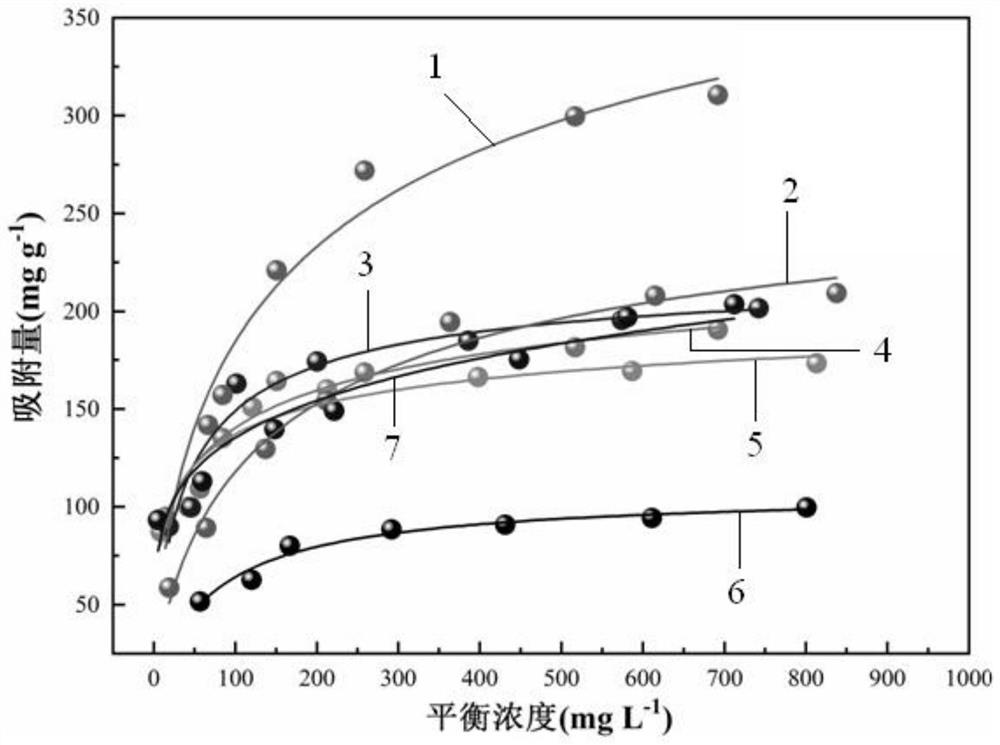

A MOF-808, bimetallic technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of low adsorption capacity, poor reusability, etc., to achieve increased adsorption capacity, Excellent repeatability, adsorption capacity, and the effect of improved adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

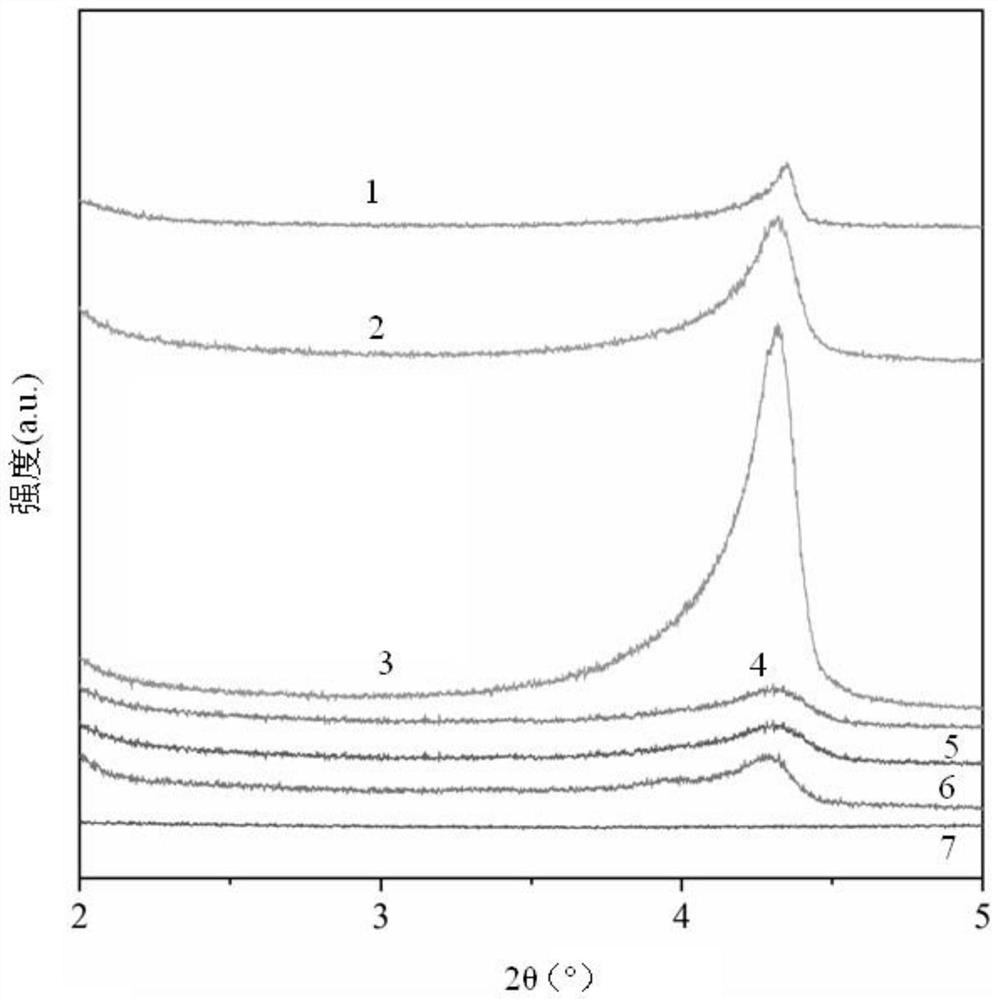

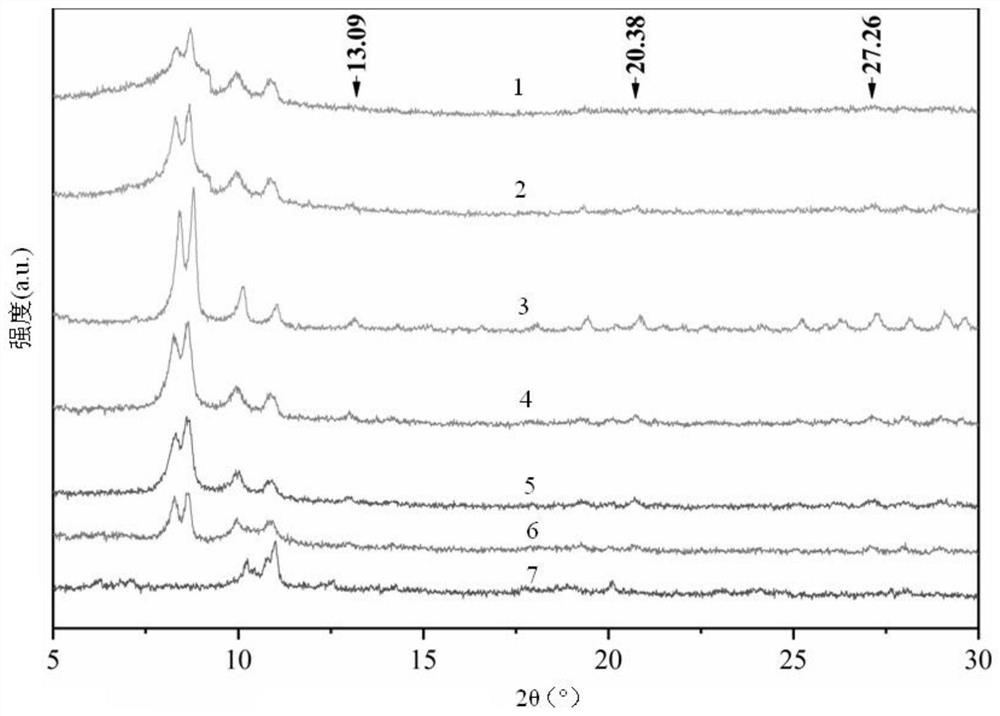

[0027] Specific implementation mode 1: This implementation mode is a method for preparing a bimetallic MOF based on MOF-808, which is specifically carried out according to the following steps:

[0028] One, the ZrOCl 2 ·8H 2 O and FeCl 3 Dissolve in DMF together, oscillate ultrasonically for 15min~20min, then add trimesic acid, continue ultrasonically oscillating for 10min~15min, then transfer to the reaction kettle, add formic acid, keep warm in an oven at 130℃~150℃ for 48h~50h, cool Suction filtration after reaching room temperature, retain the filter cake;

[0029] The ZrOCl 2 ·8H 2 O and FeCl 3 The molar ratio is 1:(0.1~4);

[0030] The FeCl 3 The volume ratio of the amount of substance to DMF is (0.8mmol~6.4mmol): 60mL;

[0031] The trimesic acid and FeCl 3 The molar ratio is 1:(0.25~1.5);

[0032] The volume of described DMF and formic acid is identical;

[0033] 2. ①Immerse the filter cake in DMF and then soak for 4h~6h, and then filter with suction; then imm...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, heat preservation in an oven at 130° C. for 48 hours, and suction filtration after cooling to room temperature to retain the filter cake. Others are the same as the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: ZrOCl described in step one 2 ·8H 2 O and FeCl 3 The molar ratio is 4:1. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com