Palm oil-based thermoplastic elastomer for digital light processing 3D printing

A thermoplastic elastomer and digital light processing technology, applied in the direction of additive processing, etc., can solve the problems of difficult solid-liquid separation in light-curing printing of thermoplastic materials, poor mechanical properties of vegetable oil elastomers, and complicated preparation processes, etc., to achieve low price, Excellent mechanical properties and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

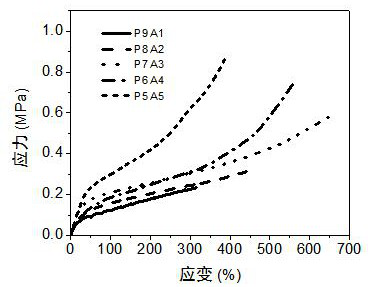

Image

Examples

Embodiment 1

[0026] Digital Light Processing 3D Printing Palm Oil-Based Thermoplastic Elastomers:

[0027] The synthesis process of palm oil fatty acid acrylamide ethyl ester: 150g palm oil and 150mL THF are placed in a three-necked flask; then add 115g N -Hydroxyethylacrylamide, 0.1g 2,6-dimethylphenol, 5g sodium hydroxide; then, place the flask in a water bath and stir it magnetically at 150 r / min at 40°C for 16 h; the reaction products are saturated After repeated purification of salt water for 3 to 5 times, it was purified by rotary evaporation to obtain palm oil fatty acid acrylamide ethyl ester.

[0028] Elastomer preparation method: Mix 18g of palm oil propylene-based monomer, 2g of acrylic acid and 0.4g of photoinitiator evenly and then pour it into a digital light processing 3D printer. Print at a speed of 20mm / h.

[0029] In the preparation process, the amount ratio of palm oil propylene-based monomer to acrylic acid is 9:1 by mass ratio; the amount of initiator is 2% of the ma...

Embodiment 2

[0031] Digital Light Processing 3D Printing Palm Oil-Based Thermoplastic Elastomers:

[0032] The synthesis process of palm oil fatty acid acrylamide ethyl ester: 150g palm oil and 150mL THF are placed in a three-necked flask; then add 115g N -Hydroxyethylacrylamide, 0.1g 2,6-dimethylphenol, 5g sodium hydroxide; then, place the flask in a water bath and stir it magnetically at 150 r / min at 40°C for 16 h; the reaction products are saturated After repeated purification of salt water for 3 to 5 times, it was purified by rotary evaporation to obtain palm oil fatty acid acrylamide ethyl ester.

[0033] Elastomer preparation method: Mix 16g of palm oil propylene-based monomer, 4g of acrylic acid and 0.4g of photoinitiator evenly and pour it into a digital light processing 3D printer. Print at a speed of 20mm / h.

[0034] In the preparation process, the amount ratio of palm oil propylene-based monomer to acrylic acid is 8:2 by mass ratio; the amount of initiator is 2% of the mass of...

Embodiment 3

[0036] Digital Light Processing 3D Printing Palm Oil-Based Thermoplastic Elastomers:

[0037] The synthesis process of palm oil fatty acid acrylamide ethyl ester: 150g palm oil and 150mL THF are placed in a three-necked flask; then add 115g N -Hydroxyethylacrylamide, 0.1g 2,6-dimethylphenol, 5g sodium hydroxide; then, place the flask in a water bath and stir it magnetically at 150 r / min at 40°C for 16 h; the reaction products are saturated After repeated purification of salt water for 3 to 5 times, it was purified by rotary evaporation to obtain palm oil fatty acid acrylamide ethyl ester.

[0038] Elastomer preparation method: Mix 14g of palm oil propylene-based monomer, 6g of acrylic acid and 0.4g of photoinitiator evenly and pour it into a digital light processing 3D printer. Print at a speed of 20mm / h.

[0039] In the preparation process, the amount ratio of palm oil propylene-based monomer to acrylic acid is 7:3 by mass ratio; the amount of initiator is 2% of the mass of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com