Fluorescent glass ceramic and preparation method thereof

A technology of glass and fluorescent powder, which is applied in the chemical industry and can solve problems such as easy melting, complicated process, and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

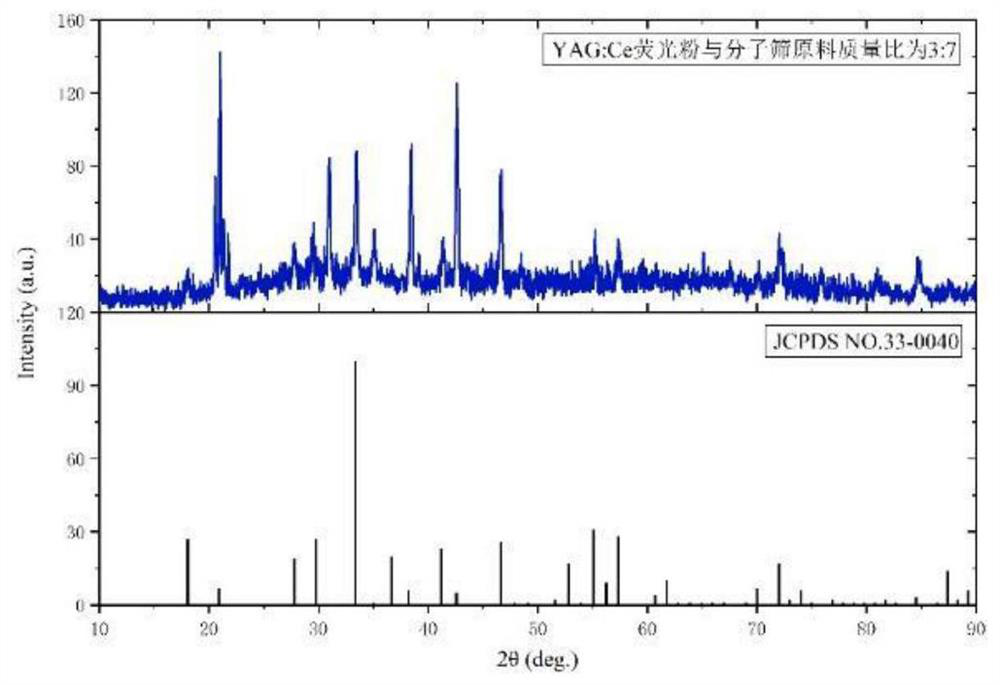

[0034] Using YAG:Ce phosphor and LTA molecular sieve as raw materials, weigh 21g of YAG:Ce phosphor and 49g of LTA molecular sieve according to the mass ratio of YAG:Ce:LTA=3:7, and weigh the weighed powder into a 3:1 ball Material ratio is loaded into the ball mill tank, and 95ml of absolute ethanol is added, and ball milled at a speed of 250r / min for 12 hours in a planetary ball mill. After the ball milling, take out the slurry, put it in a drying oven at 100°C for 12 hours, and get the raw material block after messing up, process the raw block into a suitable size, transfer it to a crucible, and put it in a box furnace at 1600°C Atmospheric pressure sintering for 5 hours, sintering LTA zeolite at high temperature, the zeolite skeleton collapses, combined with YAG:Ce phosphor, after natural cooling, 3YAG:Ce / 7LTA PiG material can be obtained.

[0035] The phase of the obtained PiG material is detected by X-ray powder diffractometer, and the detection result data shows that th...

Embodiment 2

[0040] The method of preparing PiG material in Example 2 is basically the same as that in Example 1, the raw materials used are YAG:Ce phosphor and LTA molecular sieve, the difference is that the mass ratio of YAG:Ce phosphor and LTA zeolite is 4:6.

[0041] The phase of the obtained PiG material is detected by X-ray powder diffractometer, and the detection result data shows that the phase of the obtained fluorescent material is a glass phase, and the XRD spectrum is as follows Figure 4 shown.

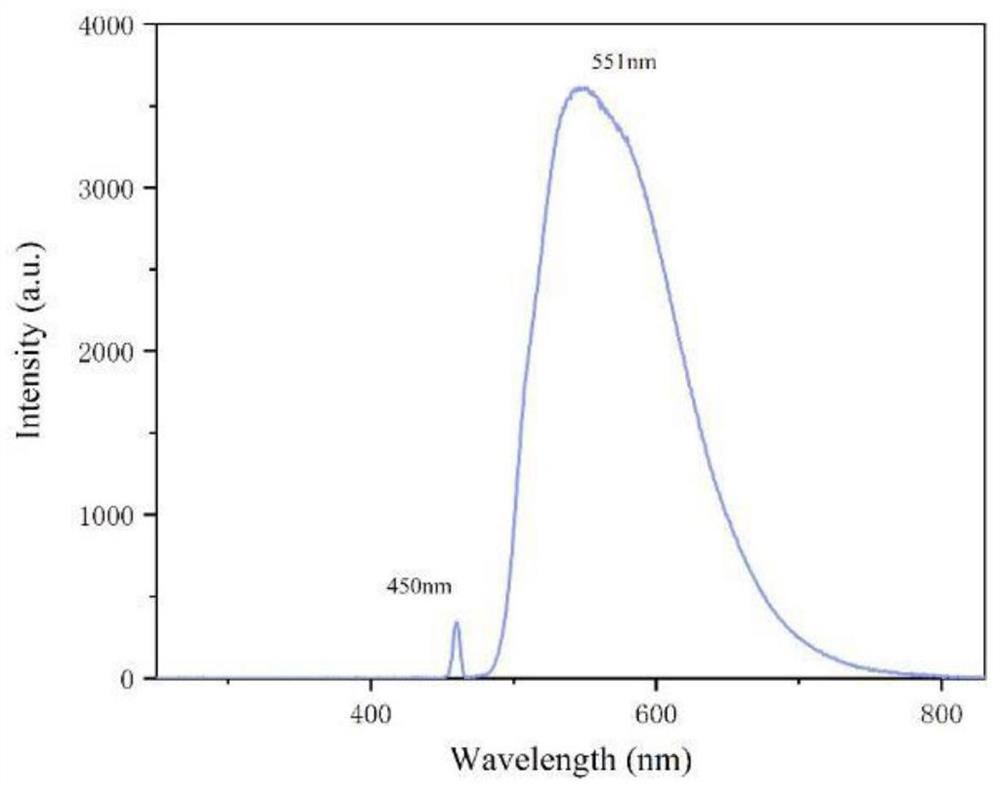

[0042] Using a fluorescence spectrometer, test the emission spectrum of the PiG material prepared in Example 1 of the present invention under the excitation of 450nm blue light, and the test results are as follows Figure 5 shown.

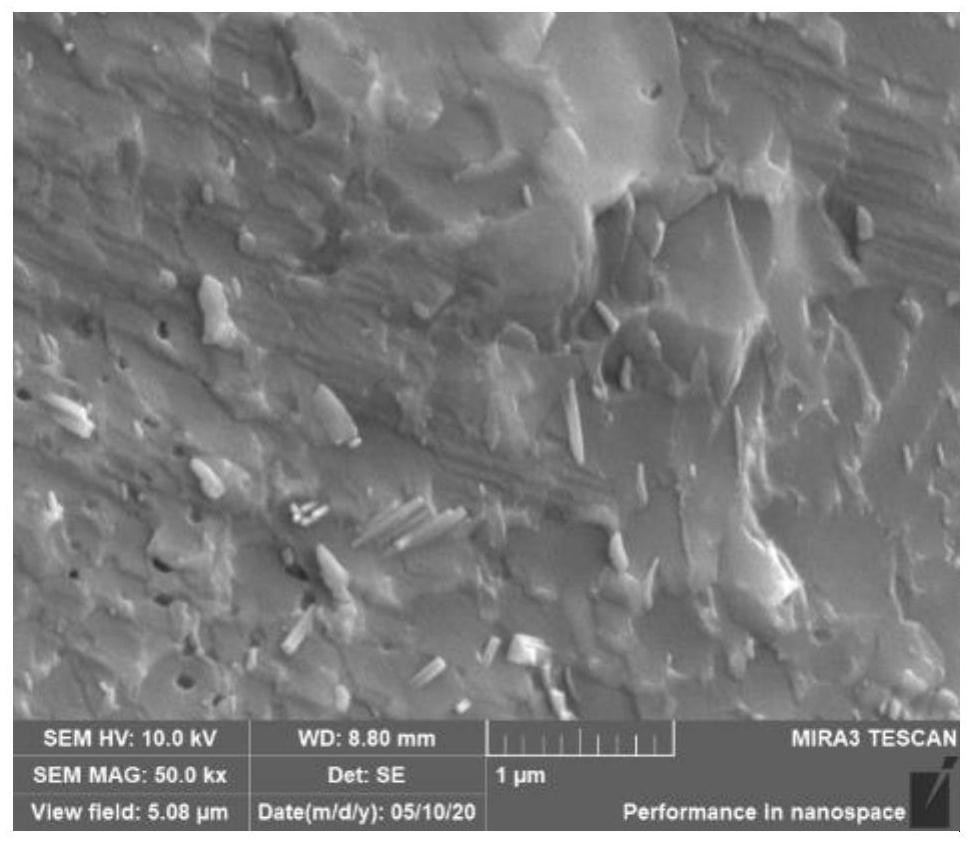

[0043] Using a scanning electron microscope, the morphology of the obtained PiG material is detected, and the SEM map is as follows Figure 6 shown.

Embodiment 3

[0045] The method for preparing PiG material in Example 3 is basically the same as Example 1. The raw materials used are YAG:Ce phosphor and LTA molecular sieve, the difference is that the mass ratio of YAG:Ce phosphor and LTA zeolite is 5:5.

[0046] The phase of the obtained PiG material is detected by X-ray powder diffractometer, and the detection result data shows that the phase of the obtained fluorescent material is a glass phase, and the XRD spectrum is as follows Figure 7 shown.

[0047] Using a fluorescence spectrometer, test the emission spectrum of the PiG material prepared in Example 1 of the present invention under the excitation of 450nm blue light, and the test results are as follows Figure 8 shown.

[0048] Using a scanning electron microscope, the morphology of the obtained PiG material is detected, and the SEM map is as follows Figure 9 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com