Device system for recovering nitric acid through nitrate thermal decomposition and using method thereof

A technology of thermal decomposition and nitrate, applied in the field of device systems for the thermal decomposition of nitrate to recover nitric acid, can solve the problems of uneven metal oxide particles, uneven heating of nitrate, poor operability, etc. Improve the effect of comprehensive economic indicators and device simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

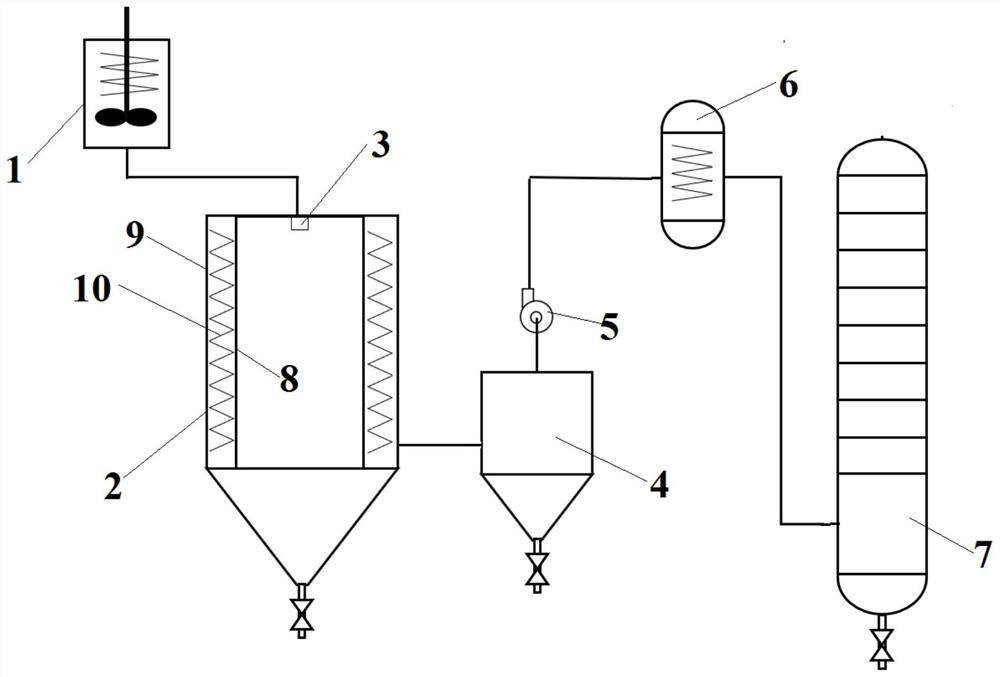

[0046] Such as figure 1 As shown, a device for recovering nitric acid by pyrolysis of nitrates includes a heating melting tank 1, a pyrolysis furnace 2, an atomizer 3, a dust collector 4, a blower fan 5, a tail gas heat exchanger 6, and a nitric acid absorption device 7;

[0047] The discharge port of the heating and melting tank 1 is connected to the top feed port of the pyrolysis furnace 2, and the middle discharge port of the pyrolysis furnace 2 is connected to the side feed port of the dust collector 4; the dust collector The top exhaust port of 4 is connected to the air inlet of tail gas heat exchanger 6 through fan 5, and the exhaust port of said tail gas heat exchanger 6 is connected to nitric acid absorption device 7;

[0048] The top of the pyrolysis furnace 2 is provided with an atomizer 3, and the atomizer 3 is used to spray nitrate hot fluid into the pyrolysis furnace 2; wherein, the pyrolysis furnace 2 is divided into an inner shell 8 and an outer shell 9, the in...

Embodiment 2

[0052] Using the same device system as in Example 1, the ferric nitrate hydrate is heated to 90°C in the heating melting tank 1 to cause it to melt, and then the ferric nitrate melt is added to the pyrolysis furnace 2 for heating and pyrolysis. The heating method adopted is The resistance wire is indirectly heated, and the temperature in the decomposition channel of the pyrolysis furnace 2 is controlled to be 550°C; the mixed gas entrained with the metal oxide powder in the pyrolysis furnace 2 is transported to the dust collector 4; the obtained Fe 2 o 3 The crystal form is a mixture of γ-type and α-type, with a particle size of 7.2 μm and good uniformity. The gas after dust collection is cooled by the tail gas heat exchanger 6, and then the cooled gas is sent to the nitric acid absorption device 7. After calculation, the thermal cost of decomposing one ton of ferric nitrate is 610 yuan, the concentration of nitric acid obtained is 48.7%, and the decomposition rate of ferric n...

Embodiment 3

[0054] Heat the ferric nitrate hydrate in the heating and melting tank 1 to 90°C to melt it, and then add the ferric nitrate melt to the pyrolysis furnace 2 for heating and pyrolysis. The heating method adopted is indirect heating by resistance wire, and the pyrolysis furnace is controlled 2 The temperature in the decomposition channel is 600°C; the mixed gas entrained with the metal oxide powder in the pyrolysis furnace 2 is sent to the dust collector 4; the obtained Fe 2 o 3 The crystal form is α-type, the particle size is 9.8 μm, and the particle size is uniform. The gas after dust collection is cooled by the tail gas heat exchanger 6, and then the cooled gas is sent to the nitric acid absorption device 7. After calculation, the thermal cost of decomposing ferric nitrate per ton is 680 yuan, the concentration of nitric acid obtained is 49.7%, and the decomposition rate of ferric nitrate is 99.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com