Design method of recycled concrete composite self-insulation building block

A technology for recycled concrete, self-insulating blocks, used in building components, sustainable waste treatment, solid waste management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

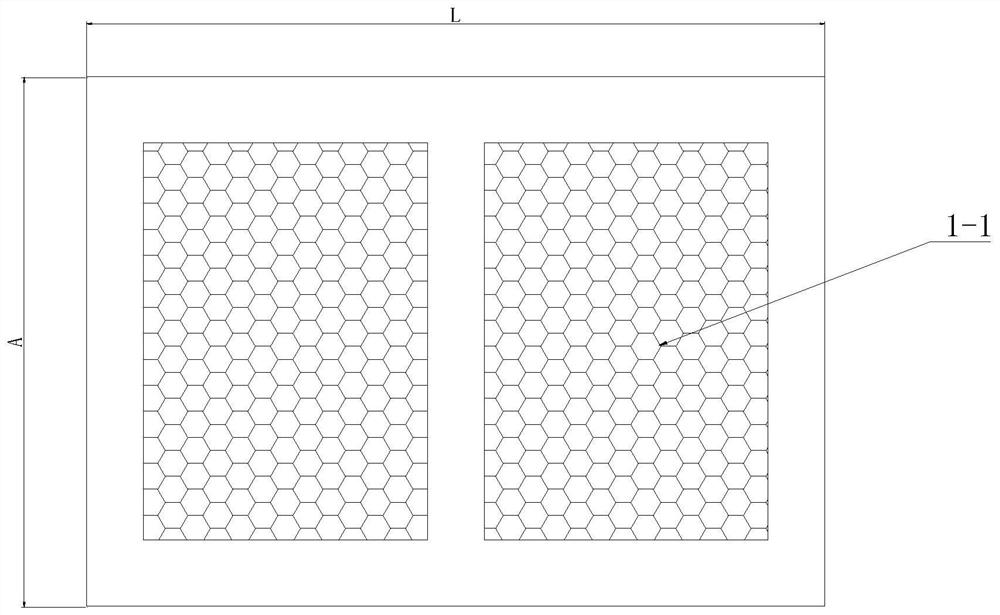

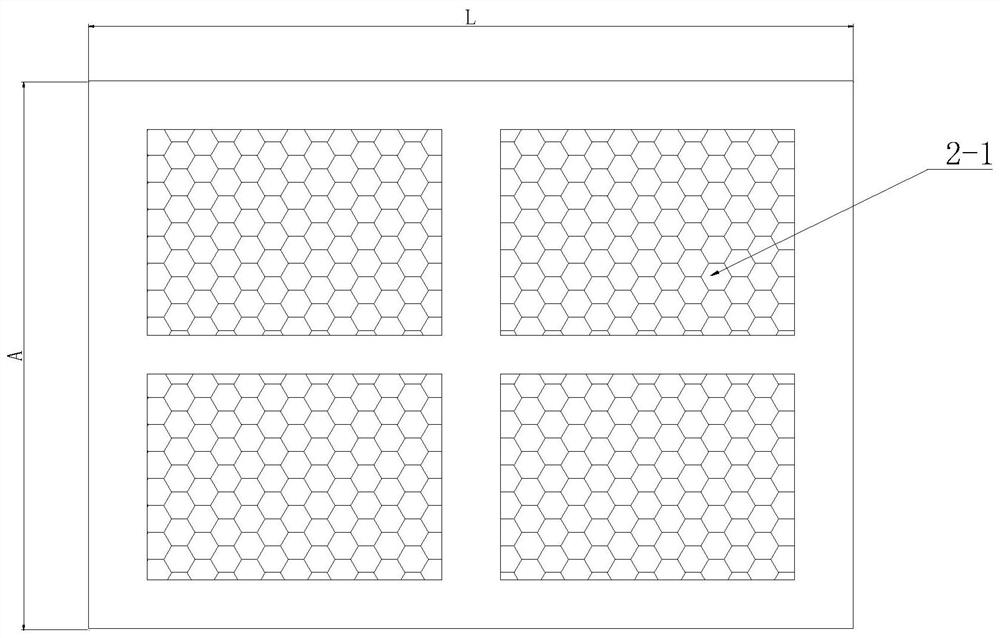

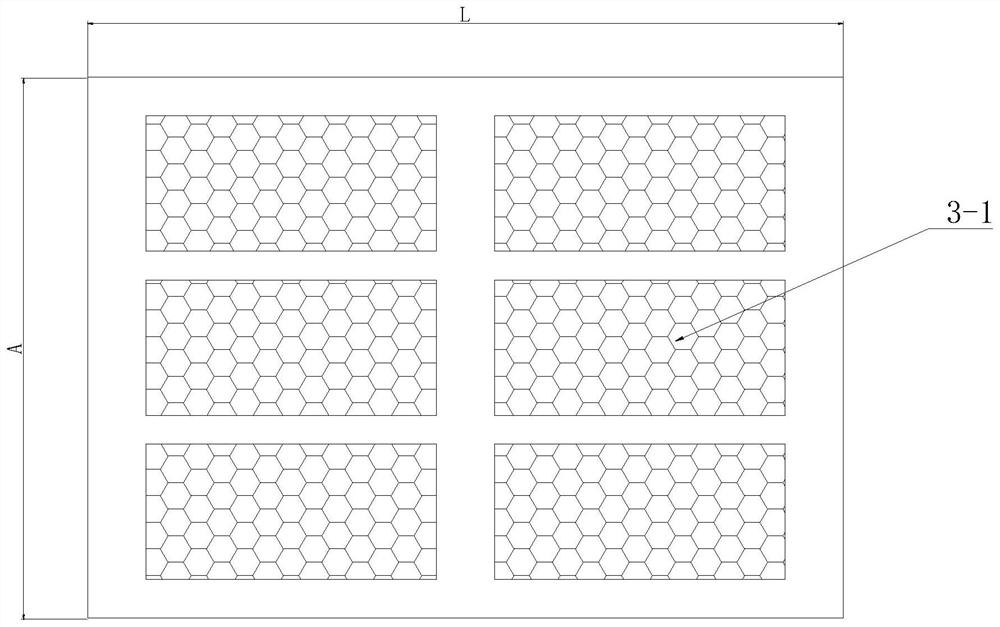

[0093] Such as Figure 1a to Figure 1h and figure 2 A design method of the shown recycled concrete composite self-insulation block comprises the following steps:

[0094] Step 1. Setting of recycled concrete composite self-insulating block parameters:

[0095] Step 101, setting the recycled concrete composite self-insulating block as a cuboid; wherein, the length of the recycled concrete composite self-insulating block is L, and the width of the recycled concrete composite self-insulating block is the recycled concrete composite self-insulating block The thickness is A, and the height of the recycled concrete composite self-insulating block is H;

[0096] Step 102, setting the recycled concrete composite self-insulating block to be provided with a through hole; wherein, the cross section of the through hole is rectangular;

[0097] Step 103, setting the porosity K of the recycled concrete composite self-insulating block x 57.7%;

[0098] Step 104, set the width of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com