Design method of heterogeneous film structure delay line type surface acoustic wave device

A technology of surface acoustic wave devices and thin-film structures, which is applied to electrical components, impedance networks, etc., can solve problems such as difficult device integration, piezoelectric single crystal substrates, difficult semiconductor technology compatibility, and inability to refine infinitely.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

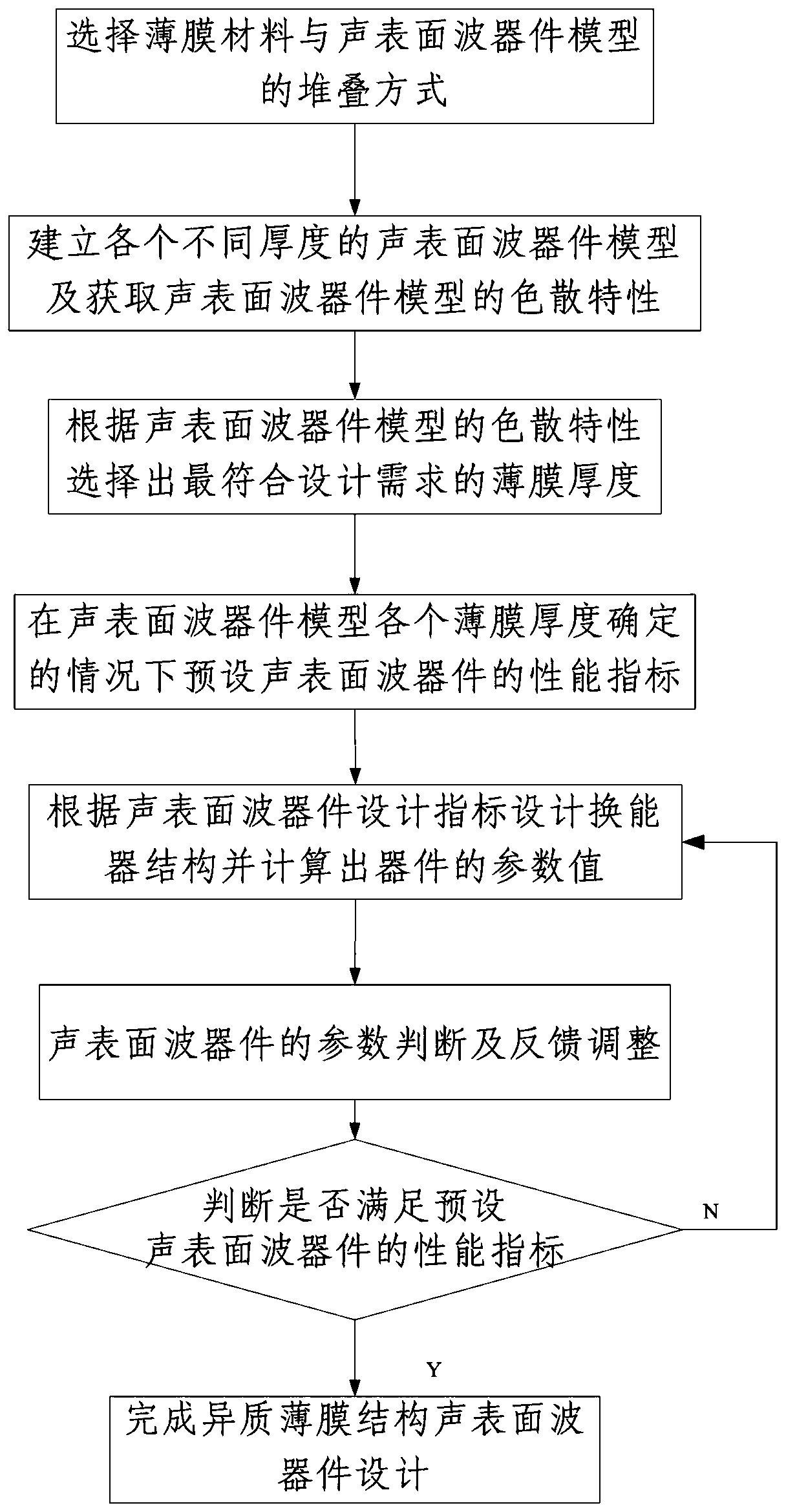

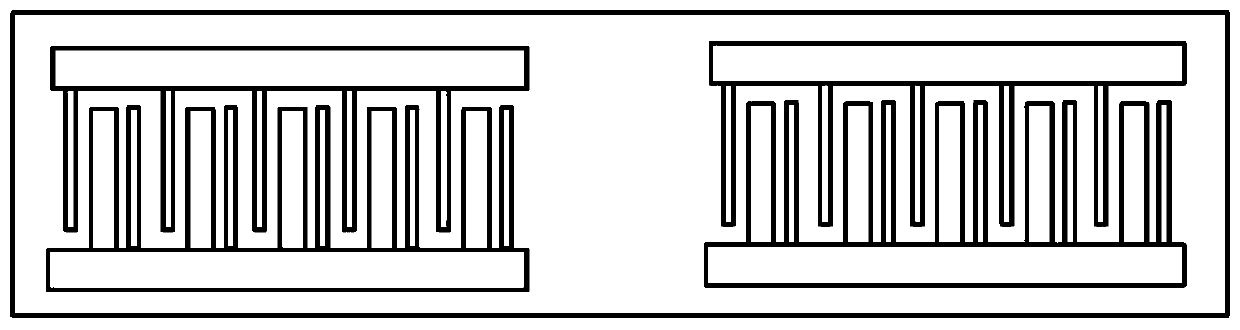

[0052] Such as figure 1 with figure 2 A method for designing a delay-line surface acoustic wave device with a heterogeneous thin-film structure is shown, the method comprising the following steps:

[0053] 1. Select the stacking method of the thin film material and the surface acoustic wave device model:

[0054] Step 101, selecting a sapphire substrate, selecting gallium nitride piezoelectric film and aluminum nitride piezoelectric film, and selecting silicon dioxide as the temperature compensation layer;

[0055] Step 102, setting the bottom-up stacking sequence of the surface acoustic wave device model as sapphire substrate, gallium nitride piezoelectric film, aluminum nitride piezoelectric film layer and temperature compensation layer;

[0056]2. Establish SAW device models with different thicknesses and obtain the dispersion characteristics of SAW device models:

[0057] Step 201, set the wavelength of the surface acoustic wave as λ, and λ=4 μm, and set the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Insertion loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com