Preparation method of composite metal oxide ozone catalyst

A composite metal and catalyst technology, applied in the field of water treatment, can solve the problem that the surface properties of ozone catalysts are easily changed and reused, and achieve high catalytic activity and stability, wide application and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

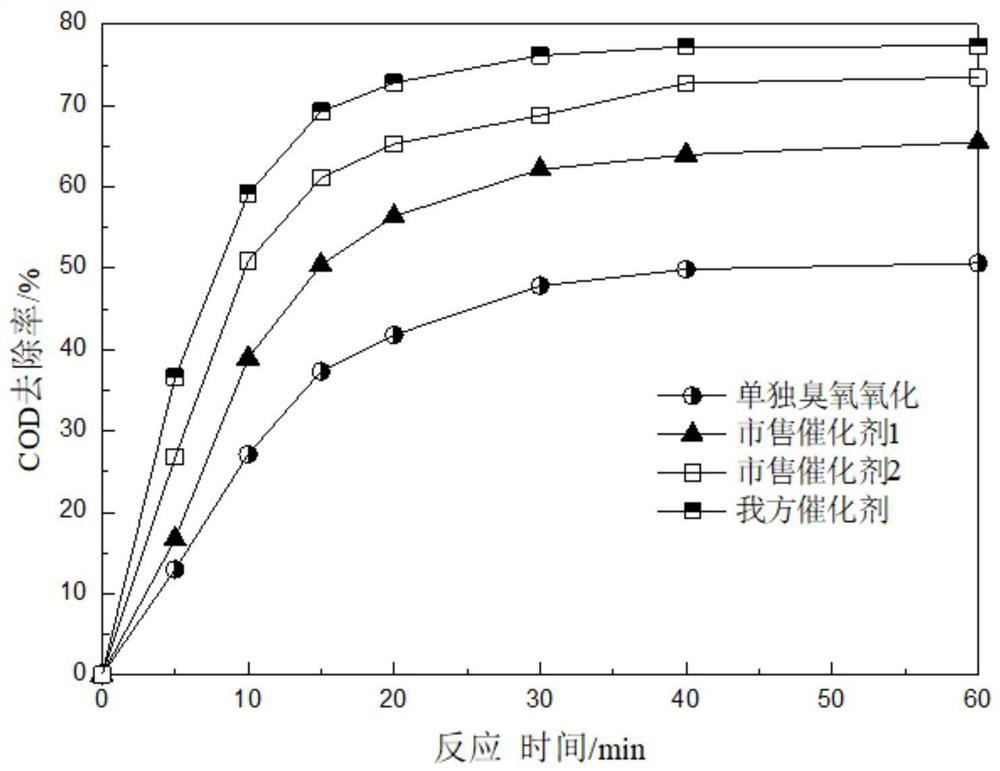

Examples

Embodiment 1

[0032] a. Activation of γ-Al 2 o 3 Ball carrier: industrial grade γ-Al 2 o 3 , carrier particle size Specific surface 300m 2 / g, pore volume 0.40m / g, abrasion 2 o 3 The ball is soaked in dilute sulfuric acid solution with pH=4 for 24 hours, washed with deionized water for 3 times until neutral, then boiled in deionized water for 3 times, washed with deionized water for 3 times until neutral, and dried in an oven at 105°C. Dry for 2 hours to obtain activated γ-Al 2 o 3 Ball carrier;

[0033] b. Preparation process of excessive impregnation method: prepare 0.5mol / L cerium nitrate and 0.5mol / L cobalt nitrate solutions respectively, and activate γ-Al in step (1) 2 o 3 Add 0.5mol / L cerium nitrate to the spherical carrier according to the dosage of 5g / L, shake and impregnate in a water bath at 60°C for 24 hours, filter out the impregnated matter with filter paper after impregnating, and put the filtered impregnated matter into 0.5mol / L L cobalt nitrate, shake and impregna...

Embodiment 2

[0038] a. Activation of γ-Al 2 o 3 Ball carrier: industrial grade γ-Al 2 o 3 , carrier particle size Specific surface 300m 2 / g, pore volume 0.4m / g, abrasion 2 o 3 The ball is first soaked in dilute sulfuric acid solution with pH=4 for 24 hours, washed with deionized water for 4 times until neutral, then boiled in deionized water for 3 times, then washed with deionized water for 4 times until neutral, and dried in an oven at 90°C. Dry for 2 hours to obtain activated γ-Al 2 o 3 Ball carrier;

[0039] b. Preparation process of excessive impregnation method: prepare 0.2mol / L cerium nitrate and 0.1mol / L cobalt nitrate solutions respectively, and activate γ-Al in step (1) 2 o 3 Add 0.2mol / L cerium nitrate to the spherical carrier according to the dosage of 8g / L, shake and impregnate in a water bath at 80°C for 36 hours, filter the impregnated matter with filter paper after impregnating, and put the filtered impregnated matter into 0.2mol / L L cobalt nitrate, shake and imp...

Embodiment 3

[0044] a. Activation of γ-Al 2 o 3 Ball carrier: industrial grade γ-Al 2 o 3 , carrier particle size Specific Surface 350m 2 / g, pore volume 0.40m / g, abrasion 2 o 3 The ball is soaked in dilute sulfuric acid solution with pH=4 for 24 hours, washed with deionized water for 5 times until neutral, then boiled in deionized water for 3 times, washed with deionized water for 5 times until neutral, and dried in an oven at 90°C. Dry for 2 hours to obtain activated γ-Al 2 o 3 Ball carrier;

[0045] b. The preparation process of excessive impregnation method: respectively prepare 0.7mol / L cerium nitrate and 0.5mol / L cobalt nitrate solutions, and activate γ-Al in step (1) 2 o 3 Add 0.7mol / L cerium nitrate to the ball carrier according to the dosage of 7g / L, shake and impregnate in a water bath at 80°C for 30h, filter out the impregnated matter with filter paper after impregnation, and put the filtered impregnated matter into 0.5mol / L Cobalt nitrate, shake and impregnate in a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com