Lycopene-based wash-free mask and preparation method thereof

A technology for lycopene and facial cleansing, applied in chemical instruments and methods, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of easy failure, affecting product use effect, poor stability of lycopene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

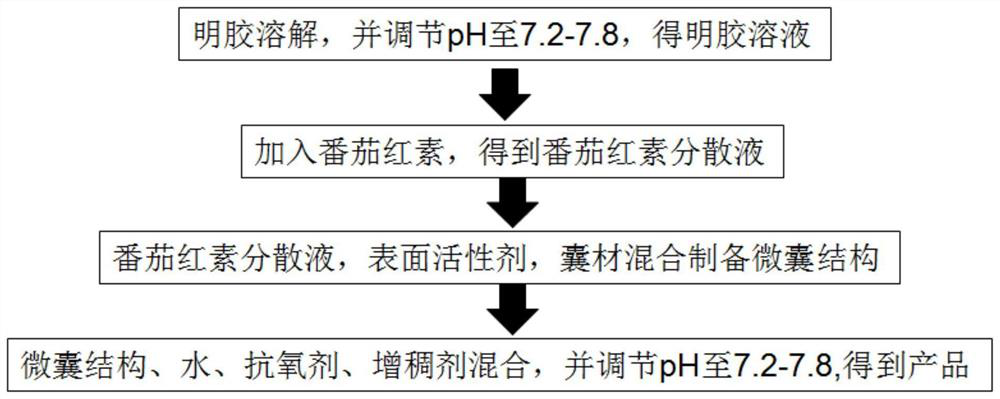

[0064] Mix gelatin and water at a mass ratio of 1:10, let it swell at room temperature for 24 hours, then heat and stir to dissolve in a digital constant temperature magnetic stirrer at a temperature of 90°C and a speed of 300r / min After that, cool to 40°C, adjust the pH to 7.2, and then add lycopene 0.3 times the mass of gelatin under the protection of nitrogen, and stir with a stirrer at a speed of 200r / min in a polytetrafluoroethylene-lined stainless steel reactor Mix for 10 minutes, and pass nitrogen protection into the reaction kettle at a rate of 3 mL / min while stirring and mixing to obtain a lycopene dispersion;

[0065] In parts by weight, take 60 parts of lycopene dispersion, 3 parts of natural surfactant, and 8 parts of capsule material in sequence, and put them in a polytetrafluoroethylene-lined stainless steel reaction kettle, stir and mix with a stirrer at a speed of 600r / min 2h, continue to feed argon into the lycopene dispersion during the stirring process, tran...

Embodiment 2

[0070] Mix gelatin and water at a mass ratio of 1:15, let it swell at room temperature for 21 hours, then heat and stir to dissolve in a digital constant temperature magnetic stirrer at a temperature of 92°C and a speed of 400r / min Afterwards, cool to 44°C, adjust the pH to 7.4, and then add lycopene 0.4 times the mass of gelatin under nitrogen protection, and stir with a stirrer at a speed of 240r / min in a polytetrafluoroethylene-lined stainless steel reactor Mix for 15 minutes, and pass nitrogen protection into the reaction kettle at a rate of 4 mL / min while stirring and mixing to obtain a lycopene dispersion;

[0071] In parts by weight, successively take 70 parts of lycopene dispersion, 4 parts of natural surfactant, and 9 parts of capsule material in a polytetrafluoroethylene-lined stainless steel reactor, stir and mix with a stirrer at a speed of 700r / min 3h, continue to feed argon into the lycopene dispersion during the stirring process, transport the material to the sp...

Embodiment 3

[0075] Mix gelatin and water at a mass ratio of 1:20, let it swell at room temperature for 36 hours, then heat and stir to dissolve in a digital constant temperature magnetic stirrer at a temperature of 95°C and a speed of 500r / min Afterwards, cool to 45°C, adjust the pH to 7.8, and then add lycopene 0.5 times the mass of gelatin under the protection of nitrogen, and stir with a stirrer at a speed of 300r / min in a polytetrafluoroethylene-lined stainless steel reactor Mix for 20 minutes, while stirring and mixing, pass nitrogen protection into the reaction kettle at a rate of 5mL / min to obtain a lycopene dispersion;

[0076] In parts by weight, take 80 parts of lycopene dispersion, 5 parts of natural surfactant, and 10 parts of capsule material in sequence, and put them in a polytetrafluoroethylene-lined stainless steel reaction kettle, stir and mix with a stirrer at a speed of 800r / min 4h, continue to feed argon into the lycopene dispersion during the stirring process, transpo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com