Salt-resistant foaming agent as well as preparation method and application thereof

A foaming agent, a technology of dodecyl dimethyl beet, applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor liquid-carrying ability, poor drainage ability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

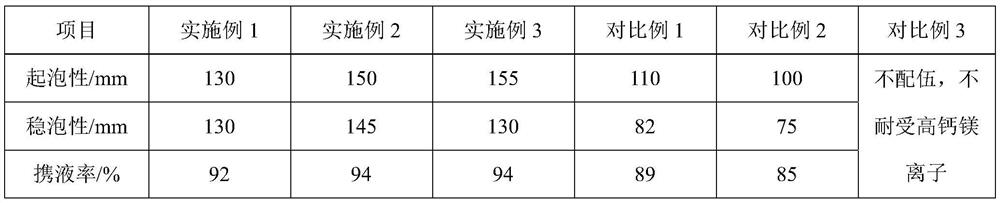

Examples

Embodiment 1

[0025] The anti-salt foaming agent of the present embodiment consists of the following components by weight percentage: 21% of cocamidopropyl amine oxide, 6% of cocoamidopropyl betaine, 3% of lauryl dimethyl betaine %, water 70%.

Embodiment 2

[0027] The anti-salt foaming agent of the present embodiment is composed of the following components by weight percentage: 35% of cocamidopropyl amine oxide, 7% of cocoamidopropyl betaine, 3% of lauryl dimethyl betaine %, water 55%.

Embodiment 3

[0029] The anti-salt foaming agent of the present embodiment is made up of the following components by weight percentage: Cocamidopropyl amine oxide 27%, Cocamidopropyl betaine 9%, Lauryl dimethyl betaine 6% %, water 58%.

[0030] In other embodiments of the anti-salt foaming agent, on the basis of the components in the above examples 1-3 of the anti-salt foaming agent, agents such as corrosion inhibitors, scale inhibitors, and methanol can be further added to meet the requirements of different gas wells. production requirements. The type of corrosion inhibitor can be imidazoline, and the addition amount can be 5%-10%. The type of scale inhibitor can be polymer, and the addition amount can be 5%-10%. After adding the above agents, the corresponding anti-salt foaming agent has good stability and has no effect on the foaming, foam stabilizing, and liquid-carrying abilities of the foaming agent, showing good compatibility.

[0031] In the following examples 1-3 of the preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com