Packaging adhesive for LED, use method and application thereof

A technology of encapsulation glue and hydroxyl end-capping, which is applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., and can solve the problems of insufficient cold and heat shock performance and damp heat resistance, high temperature resistance, and UV resistance disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

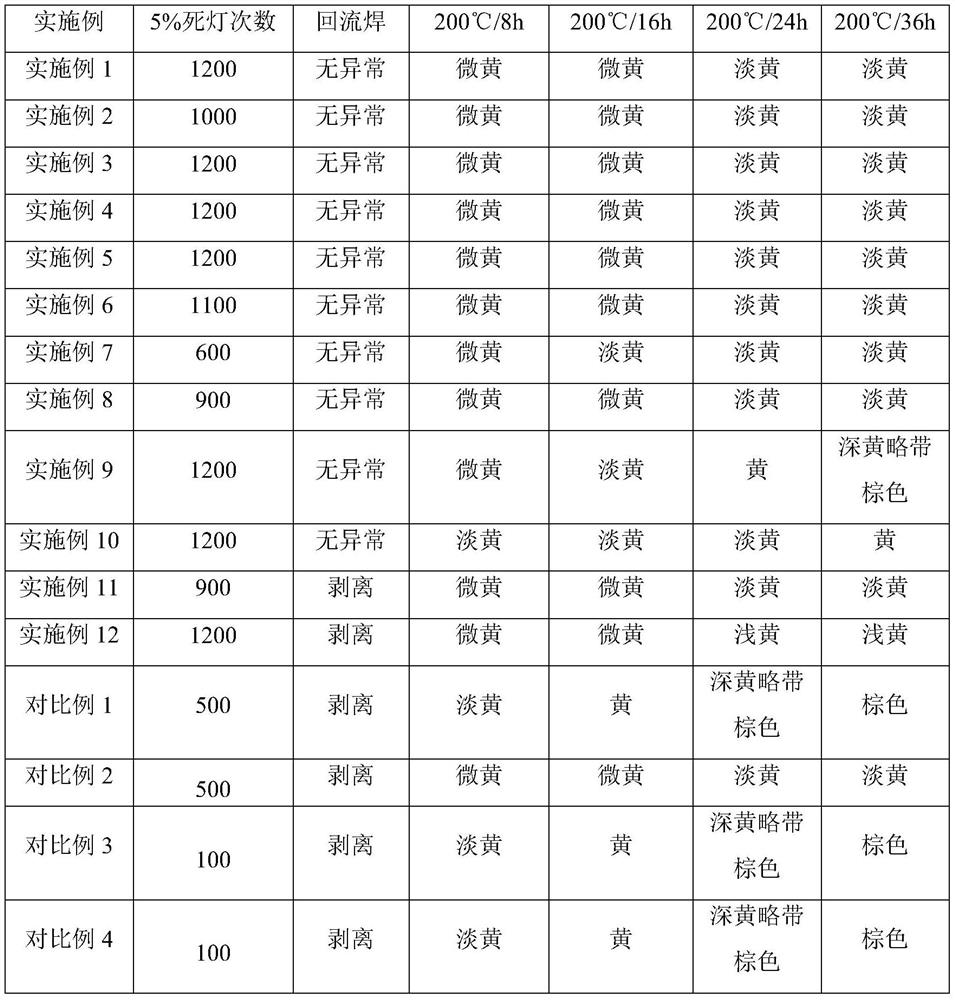

Examples

preparation example 1

[0064] The preparation method of MCY-51 (hydroxyl-terminated polyurethane prepolymer) is as follows:

[0065] 1. Vacuum dehydrate the PTMG1000 at 120°C for 2 hours;

[0066] 2. Add 548 parts by weight of PTMG-1000 and 0.5 parts by weight of dibutyltin dilaurate catalyst into the reactor, stir and mix well, and pass nitrogen protection into the reactor;

[0067] 3. Raise the temperature to an internal temperature of 70°C, add 100 parts by weight of HT-600 at a uniform speed within 2.5 hours, and control the internal temperature to not exceed 90°C;

[0068] 4. Keep the internal temperature at 80-90°C for 3 hours after feeding;

[0069] 5. Take a sample and titrate the -NCO content with the di-n-butylamine method. When the test result is 0, get MCY-51.

preparation example 2

[0071] The preparation method of MCY-22 (hydroxyl-terminated polyurethane prepolymer) is as follows:

[0072] 1. Vacuum dehydrate PEG-600 at 120°C for 2 hours;

[0073] 2. Add 315 parts by weight of PEG-600 and 0.5 parts by weight of dibutyltin dilaurate catalyst into the reactor, stir and mix well, and pass nitrogen protection into the reactor;

[0074] 3. Raise the temperature to an internal temperature of 70°C, add 100 parts by weight of HT-100 at a constant speed within 2 hours, and control the internal temperature to not exceed 90°C;

[0075] 4. Keep the internal temperature at 80-90°C for 3 hours after feeding;

[0076] 5. Take a sample and titrate the -NCO content with the di-n-butylamine method. When the test result is 0, get MCY-22.

preparation example 3

[0078] The preparation method of MCY-23 (hydroxyl-terminated polyurethane prepolymer) is as follows:

[0079] 1. Vacuum dehydrate PEG-200 at 120°C for 2 hours;

[0080] 2. Add 110 parts by weight of PEG-200 and 0.5 parts by weight of dibutyltin dilaurate catalyst into the reactor, stir and mix well, and pass nitrogen protection into the reactor;

[0081] 3. Raise the temperature to an internal temperature of 70°C, add 100 parts by weight of HT-600 at a uniform speed within 2.5 hours, and control the internal temperature to not exceed 90°C;

[0082] 4. Keep the internal temperature at 80-90°C for 3 hours after feeding;

[0083] 5. Take a sample and titrate the -NCO content with the di-n-butylamine method. When the test result is 0, get MCY-23.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com