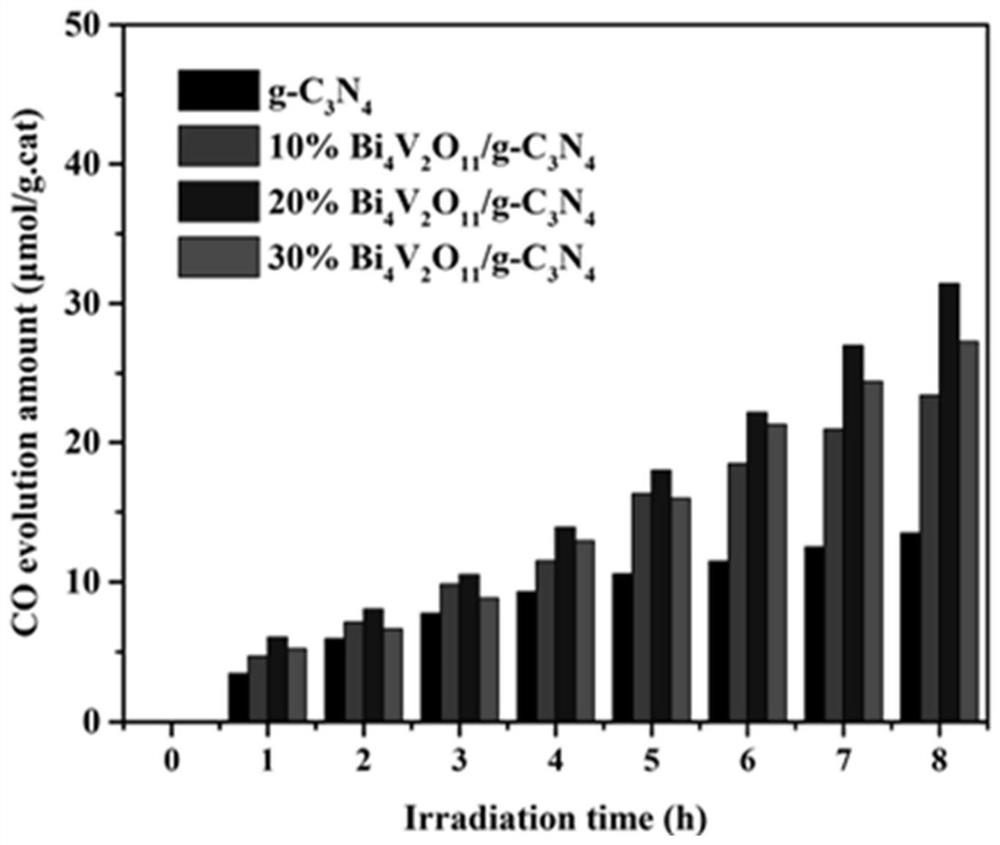

Bi4V2O11/g-C3N4 heterojunction photocatalyst and preparation method and application thereof

A bi4v2o11, 1.bi4v2o11 technology, applied in the field of Bi4V2O11/g-C3N4 heterojunction photocatalyst and its preparation, can solve the problems of low photocatalytic activity, narrow photoresponse range and high electron-hole recombination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, preparation g-C 3 N 4 Powder

[0041] g-C 3 N 4 Powder 1: Weigh 25g of urea into a glass mortar, grind for 2 hours, control the grinding rate to 30-40r / min; then transfer to an alumina crucible, wrap it with aluminum foil and seal it at a rate of 16°C / min Heating to 400°C, then holding for 2 hours; then using the same heating rate to raise to 550°C, and then holding for 2 hours; finally cooling the crucible to room temperature naturally, the obtained light yellow powder is g-C 3 N 4 Powder. The g-C 3 N 4 The powder is in the shape of curly flakes.

[0042] g-C 3 N 4 Powder 2: main preparation steps and g-C 3 N 4 Powder 1 is the same, the difference is: grinding for 4 hours.

[0043] g-C 3 N 4 Powder 3: main preparation steps and g-C 3 N 4 Powder 1 is the same, the difference is: no grinding.

[0044] g-C 3 N 4 Powder 4: Use melamine as raw material, heat to 520°C at a rate of 10°C / min, and keep warm for 4 hours.

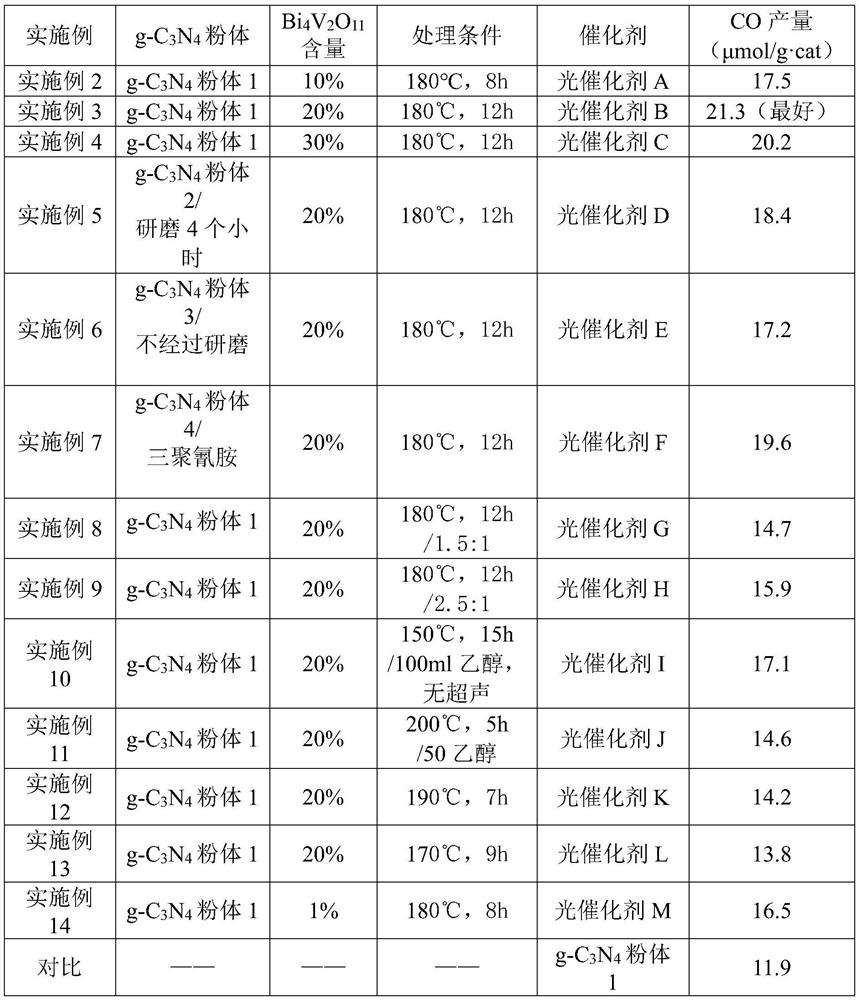

Embodiment 2、1

[0045] Example 2, 10% Bi 4 V 2 o 11 Doped Bi 4 V 2 o 11 / g-C 3 N 4 heterojunction photocatalyst

[0046] Bi 4 V 2 o 11 / g -C 3 N 4 The preparation of the heterojunction photocatalyst includes the following steps:

[0047] (1), weighing 0.5g g-C 3 N 4 Powder 1, add it to 60mL ethylene glycol, and ultrasonic treatment for 30 minutes, the ultrasonic power is 1800W, to obtain nanosheet g-C 3 N 4 The solution.

[0048] (2), add 0.095g of Bi(NO in the above-mentioned solution of step (1) subsequently 3 ) 3 ·5H 2 O and 0.012 g of NH 4 VO 3 , stirred vigorously for 30 minutes to obtain a homogeneous solution at a stirring rate of 500 r / min.

[0049] (3), transfer the homogeneous solution of step (2) into a polytetrafluoroethylene-lined autoclave, control the heat treatment at 180°C for 8 hours, then wash the resulting product 3 times with deionized water, and then wash 3 times with ethanol , and dried at 70°C for 20h to finally obtain 10% Bi 4 V 2 o 11 Doped ...

Embodiment 3

[0051] Example 3, 20% Bi 4 V 2 o 11 Doped Bi 4 V 2 o 11 / g-C 3 N 4 heterojunction photocatalyst

[0052] The basic steps of embodiment 3 are the same as embodiment 2, the difference is:

[0053] In step (2), add 0.19g of Bi(NO 3 ) 3 ·5H 2 O and 0.024 g NH 4 VO 3 .

[0054] In step (3), heat treatment at 180° C. for 12 hours.

[0055] Get 20% Bi at the end 4 V 2 o 11 Doped Bi 4 V 2 o 11 / g -C 3 N 4 Heterojunction Photocatalyst B.

[0056] against Bi 4 V 2 o 11 / g -C 3 N 4 Heterojunction photocatalyst B is detected by XRD, the results are as follows figure 1 shown. Depend on figure 1 It can be seen that the Bi prepared in Example 3 4 V 2 o 11 / g -C 3 N 4 Heterojunction photocatalyst B includes Bi 4 V 2 o 11 and g-C 3 N 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com