Perovskite battery and preparation method thereof

A perovskite cell, perovskite technology, applied in the field of solar cells, can solve the problems of large optics, thin film optics, narrow band gap, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

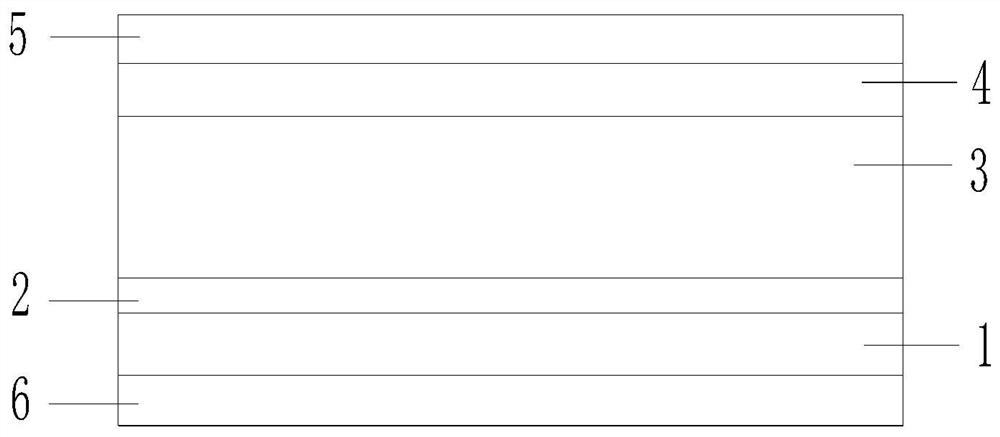

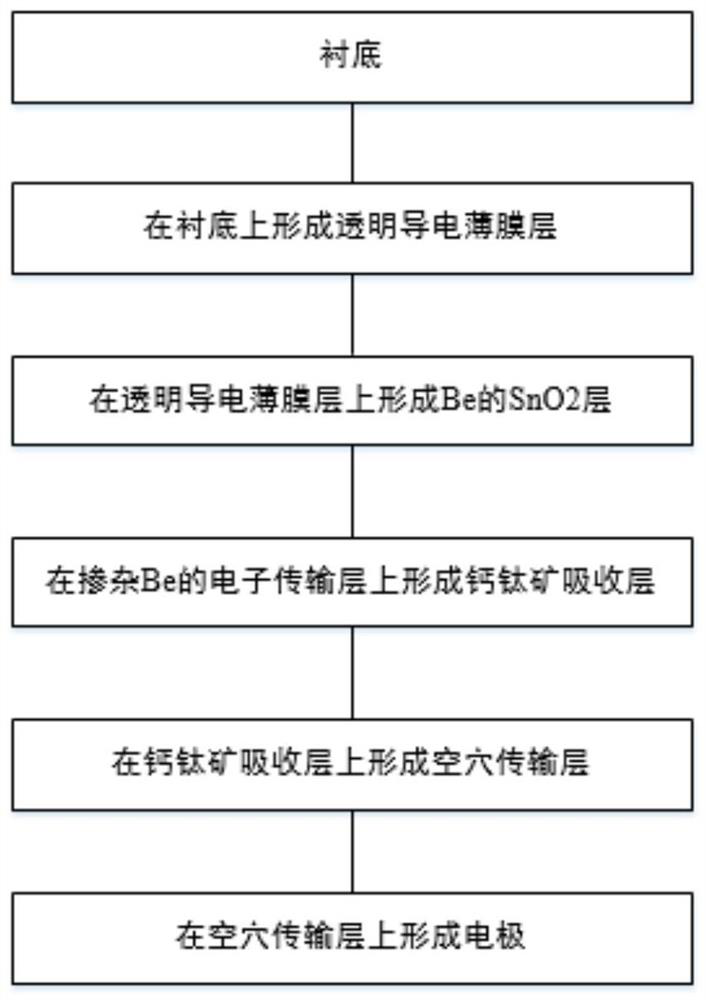

[0065] Select glass substrate as the substrate;

[0066] Depositing an ITO transparent conductive film layer with a thickness of 200nm on the substrate;

[0067] Deposit Be-containing SnO with a thickness of 50nm on the ITO transparent conductive film layer 2 thin film layer, where SnO 2 : Be molar ratio is 1:0.05;

[0068] In Be-containing SnO 2 Spin-coat FAPbI with a thickness of 500 nm on the thin film layer 3 film layer;

[0069] In FAPbI 3 The Spiro-OMeTAD film layer with a thickness of 100nm is spin-coated on the film layer;

[0070] On the Spiro-OMeTAD thin film layer, gold with a thickness of 80nm was vapor-deposited as an electrode.

Embodiment 2

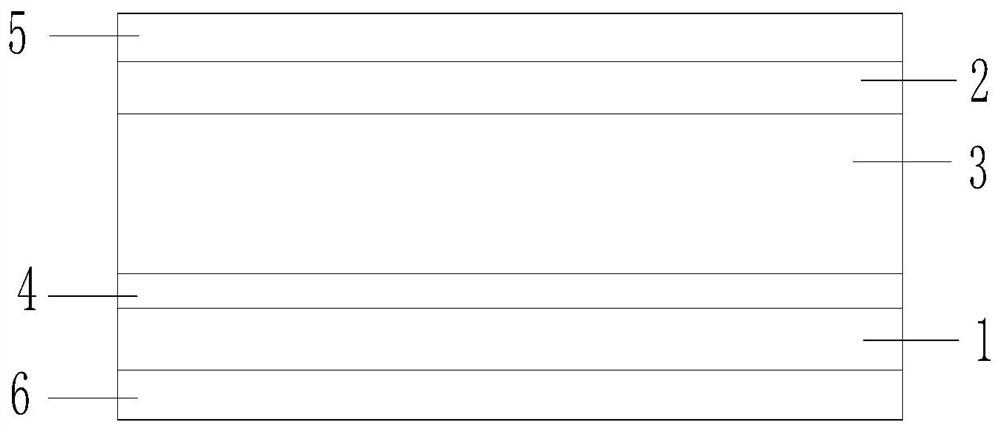

[0072] Select glass substrate as the substrate;

[0073] Depositing an ITO transparent conductive film layer with a thickness of 200nm on the substrate;

[0074] Deposit Be-containing SnO with a thickness of 50nm on the ITO transparent conductive film layer 2 thin film layer, where SnO 2 : Be molar ratio is 1:0.09;

[0075] In Be-containing SnO 2 Spin-coat FAPbI with a thickness of 500 nm on the thin film layer 3 film layer;

[0076] In FAPbI 3 The Spiro-OMeTAD film layer with a thickness of 100nm is spin-coated on the film layer;

[0077] On the Spiro-OMeTAD thin film layer, gold with a thickness of 80nm was vapor-deposited as an electrode.

Embodiment 3

[0079] Select glass substrate as the substrate;

[0080] Depositing an ITO transparent conductive film layer with a thickness of 200nm on the substrate;

[0081] Deposit Be-containing SnO with a thickness of 50nm on the ITO transparent conductive film layer 2 thin film layer, where SnO 2 : Be molar ratio is 1:0.01;

[0082] In Be-containing SnO 2 Spin-coat FAPbI with a thickness of 500 nm on the thin film layer 3 film layer;

[0083] In FAPbI 3 The Spiro-OMeTAD film layer with a thickness of 100nm is spin-coated on the film layer;

[0084] On the Spiro-OMeTAD thin film layer, gold with a thickness of 80nm was vapor-deposited as an electrode.

[0085] For the perovskite cell that comparative example, embodiment 1, embodiment 2 and embodiment 3 make are tested, adopt the steady-state light source IV tester to measure the current density of battery (mA / cm 2 ), voltage (V), fill factor and Eff (photoelectric conversion efficiency) to obtain the test results shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com