a kind of vo 2 Alloy semiconductor thin film, preparation method and application

A semiconductor and thin film technology, applied in the field of semiconductor optoelectronic materials, can solve the problems of low visible light transmittance, high phase transition temperature, etc., and achieve the effect of increasing visible light transmittance, reducing phase transition temperature, and increasing optical bandgap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

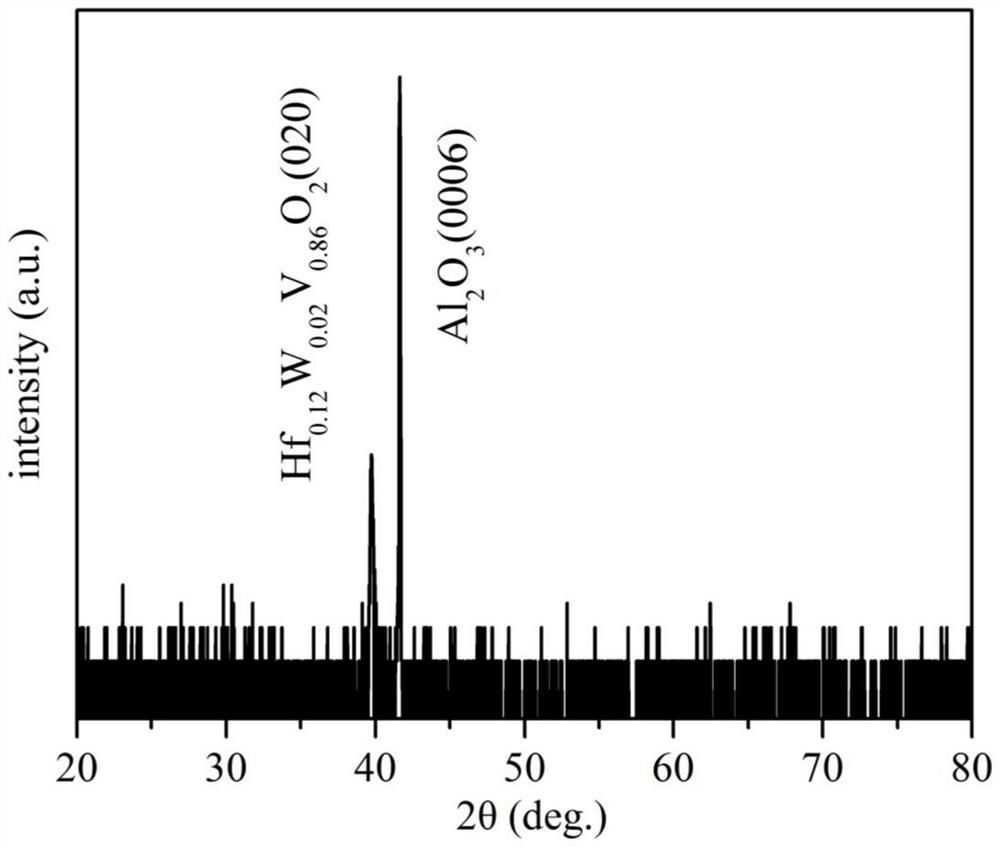

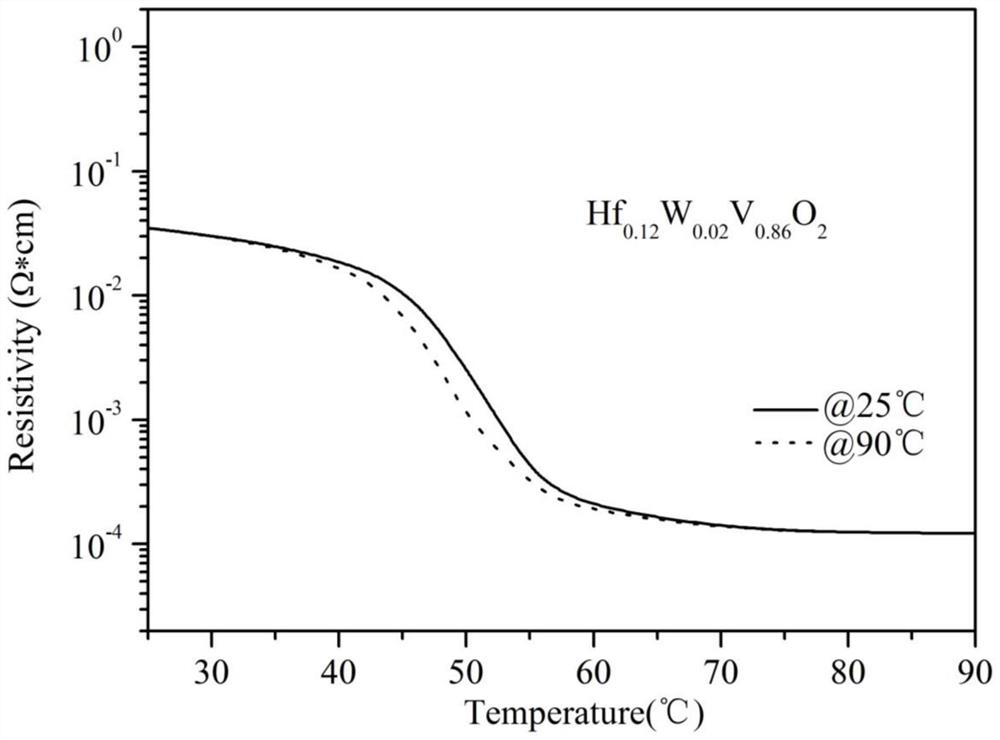

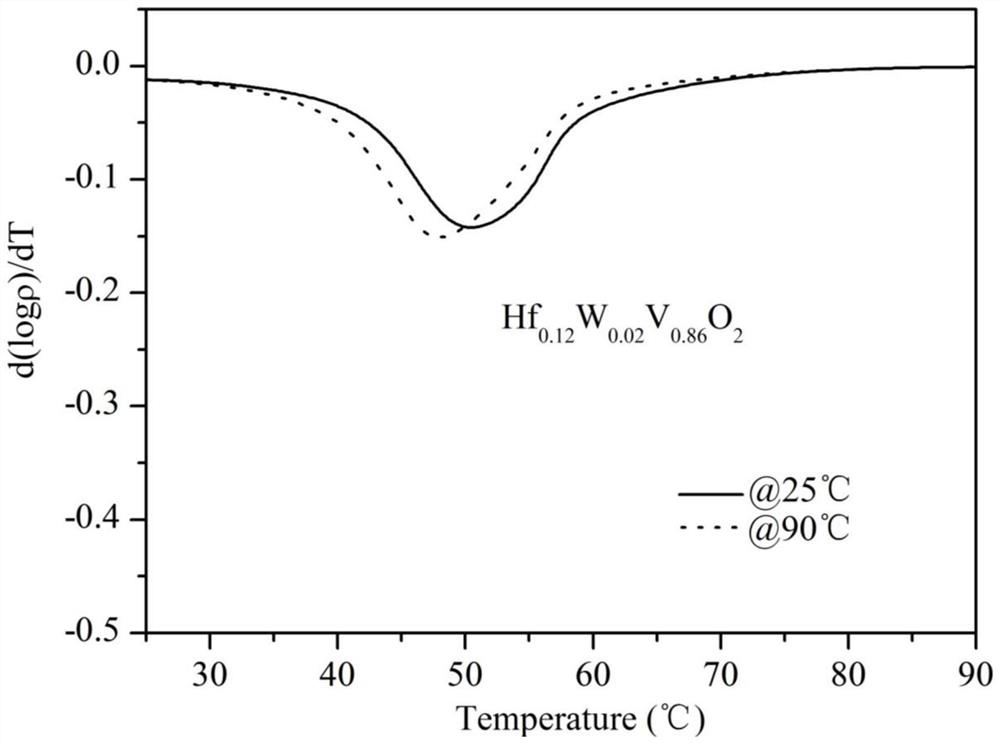

[0045] The invention provides an alloy semiconductor thin film, the chemical formula of the thin film is Hf 0.12 W 0.02 V 0.86 o 2 .

[0046] It should be noted that the present invention uses W 6+ Ion doping to effectively reduce VO 2 Phase transition temperature, Hf 4+ Ion doping to increase VO 2 The optical bandgap of the film, so that Hf x W y V 1-x-y o 2 Alloy semiconductor films have high visible light transmittance and a phase transition temperature close to room temperature. Specifically, the present invention utilizes HfO 2 The bandgap (5.5eV) is larger than VO 2 bandgap (2.6eV), using Hf 4+ Ionic partial replacement of V 4+ ions, to increase VO 2 The optical bandgap effectively increases the visible light transmittance of the film. At the same time, W ion is +6 valence, in VO 2 W 6+ The ions are equivalent to the introduction of carriers. The more carriers are introduced, the easier it is to drive the electronic phase transition, so the phase transi...

Embodiment 2

[0060] The invention provides an alloy semiconductor thin film, the chemical formula of the thin film is Hf 0.11 W 0.03 V 0.86 o 2 .

[0061] Based on the same inventive concept, the embodiment of the present application also provides a method for preparing the alloy semiconductor thin film, including the following steps:

[0062] S11. Provide a substrate;

[0063] S12. Prepare a thin film on the surface of the substrate by pulse laser ablation, magnetron sputtering or electron beam evaporation.

[0064] It should be noted that, in the implementation of this application, the substrates include c-plane sapphire substrates or glass substrates, silicon or quartz glass substrates, GaN / sapphire (silicon) substrates, etc.; sapphire substrates, whose main component is aluminum oxide (Al 2 o 3 ), c-Al 2 o 3 Indicates c-plane sapphire; in the implementation of this application, the thickness of the c-plane sapphire substrate is 0.35-0.45mm;

[0065] Specifically, in the embod...

Embodiment 3

[0074] The invention provides an alloy semiconductor thin film, the chemical formula of the thin film is Hf 0.10 W 0.04 V 0.86 o 2 .

[0075] Based on the same inventive concept, the embodiment of the present application also provides a method for preparing the alloy semiconductor thin film, including the following steps:

[0076] S11. Provide a substrate;

[0077] S12. Prepare a thin film on the surface of the substrate by pulse laser ablation, magnetron sputtering or electron beam evaporation.

[0078] It should be noted that, in the implementation of this application, the substrates include c-plane sapphire substrates or glass substrates, silicon or quartz glass substrates, GaN / sapphire (silicon) substrates, etc.; sapphire substrates, whose main component is aluminum oxide (Al 2 o 3 ), c-Al 2 o 3 Indicates c-plane sapphire; in the implementation of this application, the thickness of the c-plane sapphire substrate is 0.35-0.45mm;

[0079] Specifically, in the embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com