Annealing method of oxide semiconductor film by utilizing deep ultraviolet laser

An oxide semiconductor and deep ultraviolet technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of inability to meet large-scale and low-temperature processing, long annealing time, easy to damage the substrate, etc., and the time to reach is short. , the treatment range can be selected, the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

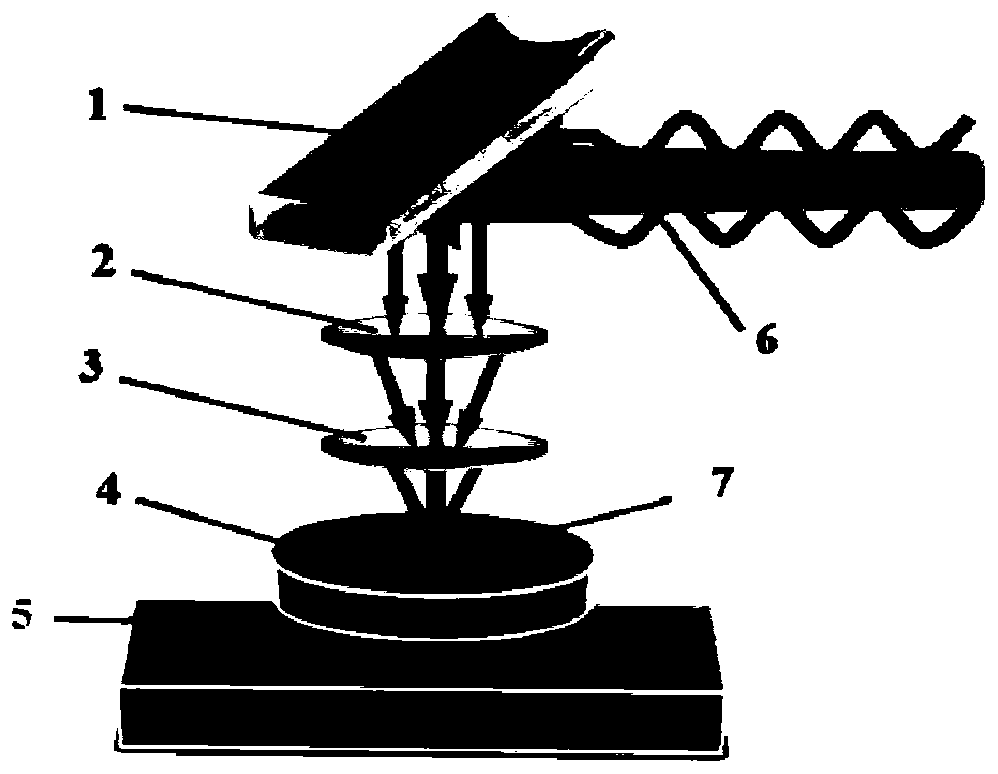

[0030] A method for annealing an oxide semiconductor thin film using a deep ultraviolet laser, comprising the following steps:

[0031] First, prepare an amorphous oxide semiconductor thin film on a clean glass substrate with a vacuum magnetron sputtering apparatus;

[0032] Next, treat the film with a deep ultraviolet laser: (1) Set the beam moving speed to 1230mm / s; (2) Set the energy density and power of the laser according to the thickness of the film sample, and then set the horizontal overlap and vertical spacing of the beam movement ; (3) Place the film flat on the sample stage, set the minimum distance between the laser lens and the sample to be 101 μm, and scan the light beam horizontally and continuously on the film sample according to the above parameters until all areas are affected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical spacing | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com