Ultraviolet light emitting diode element structure and manufacturing method thereof

A light-emitting diode, ultraviolet light technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of light-emitting diode components output optical power attenuation is not significantly improved, low light extraction efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

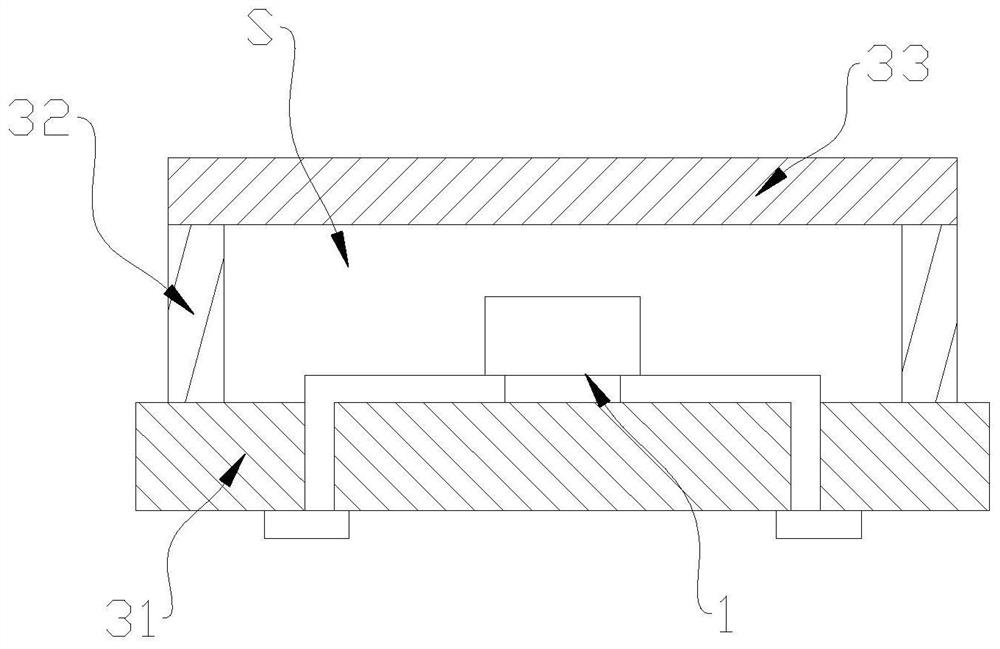

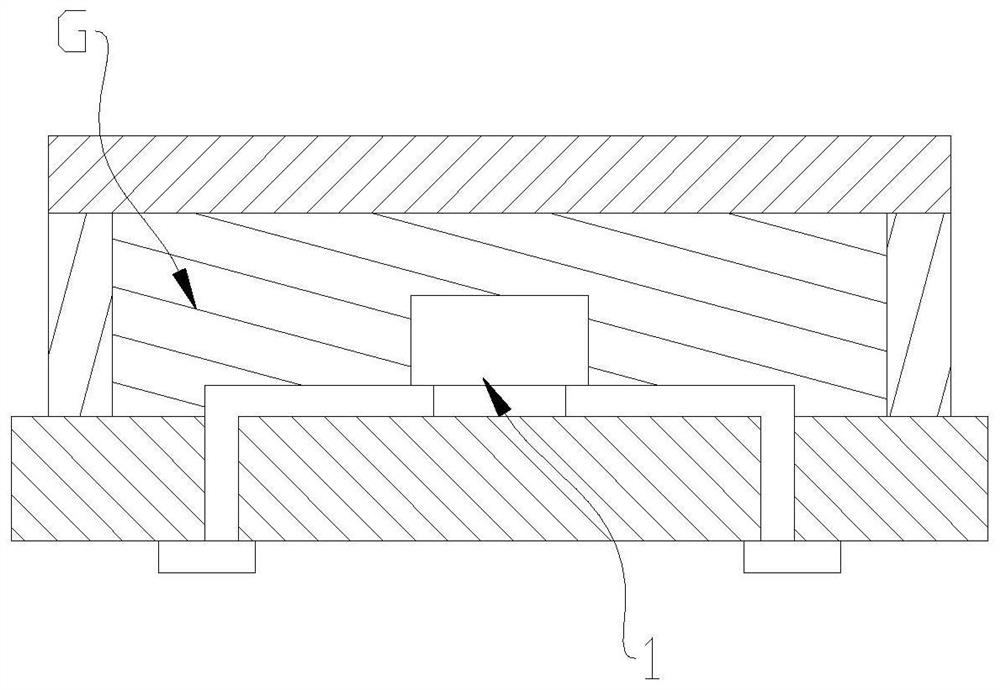

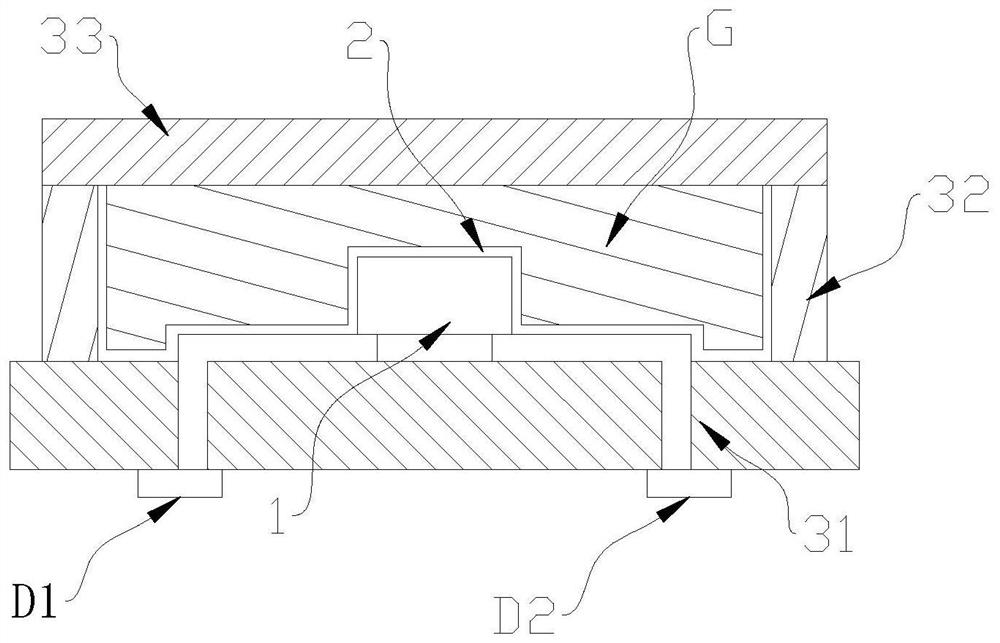

[0073] Embodiment 1, with reference to image 3 : A kind of ultraviolet light emitting diode element structure that the present invention proposes, comprises:

[0074] A support portion; the support portion includes: a support 31; the positive electrode D1 and the negative electrode D2 are all arranged on the support 31; the support 31 can be an existing high thermal conductivity ceramic material of aluminum nitride or aluminum oxide production.

[0075] A dam 32 is arranged on the support 31 .

[0076] A light-transmitting portion, the light-transmitting portion includes a quartz glass cover plate 33, the quartz glass cover plate 33 is arranged on the end of the dam 32 away from the bracket 31, the quartz glass cover plate 33, the The dam 32 and the bracket 31 are enclosed to form an accommodation space S, and the accommodation space S is filled with silicone oil G;

[0077] At least one ultraviolet light emitting diode chip 1 is located in the accommodating space S and ar...

Embodiment 2

[0099] Example 2, combined with Figure 4 :

[0100] The transparent part includes a quartz glass tube 41 .

[0101] The support part includes:

[0102] A cover 42 is installed on the open end of the quartz glass tube 41, the cover is provided with a polytetrachlorethylene layer, and the cover 42 and the quartz glass tube 41 are enclosed to form an accommodation space S; The space S is filled with silicone oil G.

[0103] Both the positive electrode D1 and the negative electrode D2 are disposed on the cover.

[0104] A bracket 43 is located in the accommodating space S, and the bracket 43 is installed on the substrate 44. The bracket can be made of existing ceramic materials with high thermal conductivity such as aluminum nitride or aluminum oxide; the ultraviolet light emitting diode chip 1 is arranged on the support 43, and is electrically connected with the positive electrode D1 and the negative electrode D2; wherein,

[0105] The protective layer is provided between t...

Embodiment 3

[0109] Example 3, combined with Figure 5 :

[0110] The transparent part includes a quartz glass tube 51 .

[0111] The support part includes:

[0112] A cover 52 is installed on the open end of the quartz glass tube 51, the cover is provided with a polytetrachlorethylene layer, and the cover 52 and the quartz glass tube 51 are enclosed to form the accommodation space S ; The accommodating space S is filled with silicone oil G.

[0113] The positive electrode D1 and the negative electrode D2 are both arranged on the cover and electrically connected to the ultraviolet light emitting diode chip;

[0114] A substrate 54 is located in the accommodation space S, and a heat conduction layer is provided on the substrate; the ultraviolet light emitting diode chip 1 is arranged on the substrate 54; wherein,

[0115] The protective layer is disposed between the substrate 54 , the cover 52 and the silicone oil G.

[0116] Further, the protective layer 2 is SiO x thin film, the SiO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com