Production method of high-purity pseudo-boehmite, and produced high-purity pseudo-boehmite

A pseudo-boehmite, production method technology, applied in the production of hydrogen, chemical instruments and methods, aluminum compounds, etc., can solve the problems of difficulty in recycling, complex preparation process of pseudo-boehmite, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

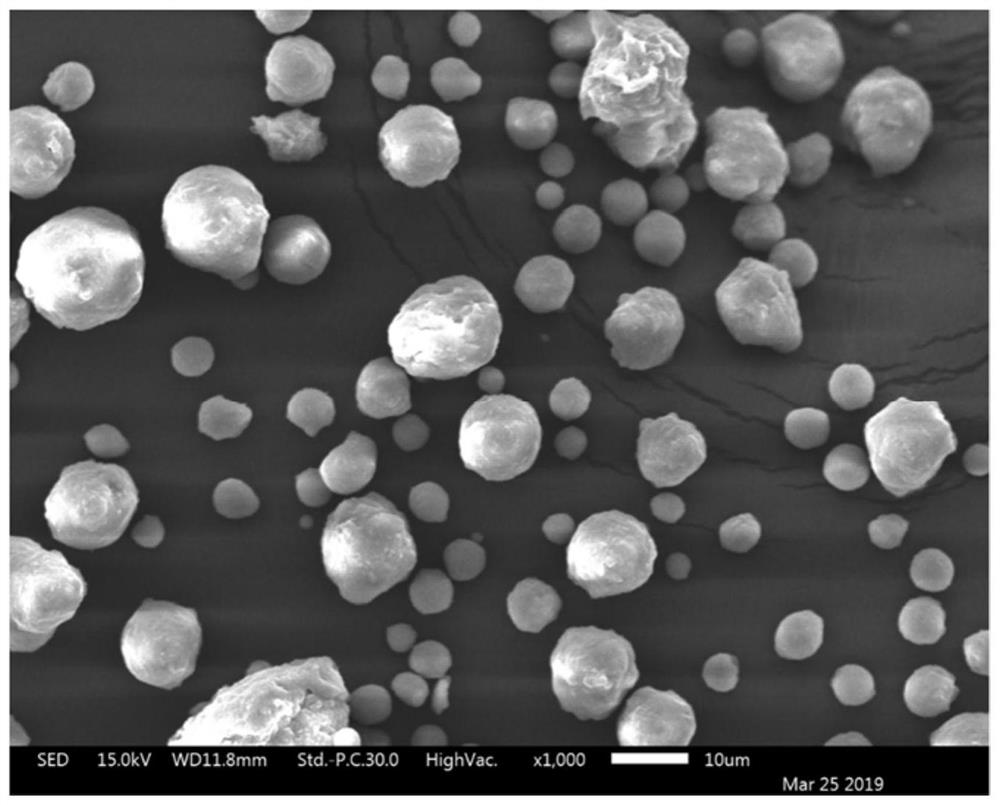

Image

Examples

Embodiment 1

[0030] Weigh 400g of a metal aluminum ingot with an aluminum content of 99.9wt%, and also weigh 0.04g of metal gallium and indium (including 0.0316g of gallium and 0.0084g of indium), and place them in a stirred intermediate frequency vacuum melting furnace at a vacuum of 1.0~ 1.0×10 -1 Under the conditions of Pa, smelt at 800℃ for 30min, stirring continuously during the stirring speed at 300 rpm, and then pouring into a mold, and after natural cooling, the aluminum ingot is obtained. The aluminum ingot is cut and refined into particles of 0.2-0.8 cm. The mass ratio of aluminum gallium indium in the aluminum ingot is: 100:0.0079:0.0021, and gallium indium accounts for 0.01wt% of the total metal mass; add 8L of pure water into the pressurized reactor, heat to 95°C, add aluminum particles while stirring, and continue Heating makes the water boil; as the reaction between aluminum and water progresses, the gas pressure in the reactor rises, the gas is led out of the supercooled hydr...

Embodiment 2

[0033] Weigh 400g of a metal aluminum ingot with an aluminum content of 99.9wt%, and also weigh 0.40g of gallium and indium (including 0.316g of gallium and 0.084g of indium), and place them in a stirred intermediate frequency vacuum melting furnace at a vacuum of 1.0~ 1.0×10 -1 Under the condition of Pa, smelt at 800℃ for 30min, stirring continuously during the process, the stirring speed is 300 rpm, and then poured into the mold, after natural cooling, the aluminum ingot is obtained. The aluminum ingot is cut and refined into 0.5-1cm particles. The mass ratio of aluminum, gallium and indium in the ingot is: 100:0.079:0.021, and gallium and indium account for 0.1wt% of the total metal mass; add 8L of pure water into the pressurized reactor, heat to 95°C, add aluminum particles while stirring, and continue heating Make the water boil; as the reaction between aluminum and water progresses, the gas pressure in the reactor increases, the gas is led out of the supercooled hydrazine,...

Embodiment 3

[0036] Weigh 400g of a metal aluminum ingot with an aluminum content of 99.9wt%, and also weigh 0.8g of metal gallium and indium (including 0.632g of gallium and 0.168g of indium), and place them in a stirred argon-protected smelting furnace at 1.1×10 5 Under the condition of Pa, smelt at 800℃ for 30min, stirring continuously during the process, the stirring speed is 300 rpm, and then poured into the mold, after natural cooling, the aluminum ingot is obtained. The aluminum ingot is cut and refined into 0.2-1cm particles. The mass ratio of aluminum gallium indium in the ingot is: 100:0.158:0.042, and gallium indium accounts for 0.2wt% of the total metal mass; add 8L of pure water into the pressurized reactor, heat to 95°C, add aluminum particles while stirring, and continue heating Make the water boil; as the reaction between aluminum and water progresses, the gas pressure in the reactor rises, the gas is led out of the supercooled hydrazine, the water is separated, and the hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com