Method of manufacturing insulating circuit board with heat sink

A technology for circuit substrates and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, circuits, manufacturing tools, etc., and can solve the problems of reduced reliability of bonding between metal layers and heat sinks, insufficient solid-phase diffusion, and high activation energy of 4N aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

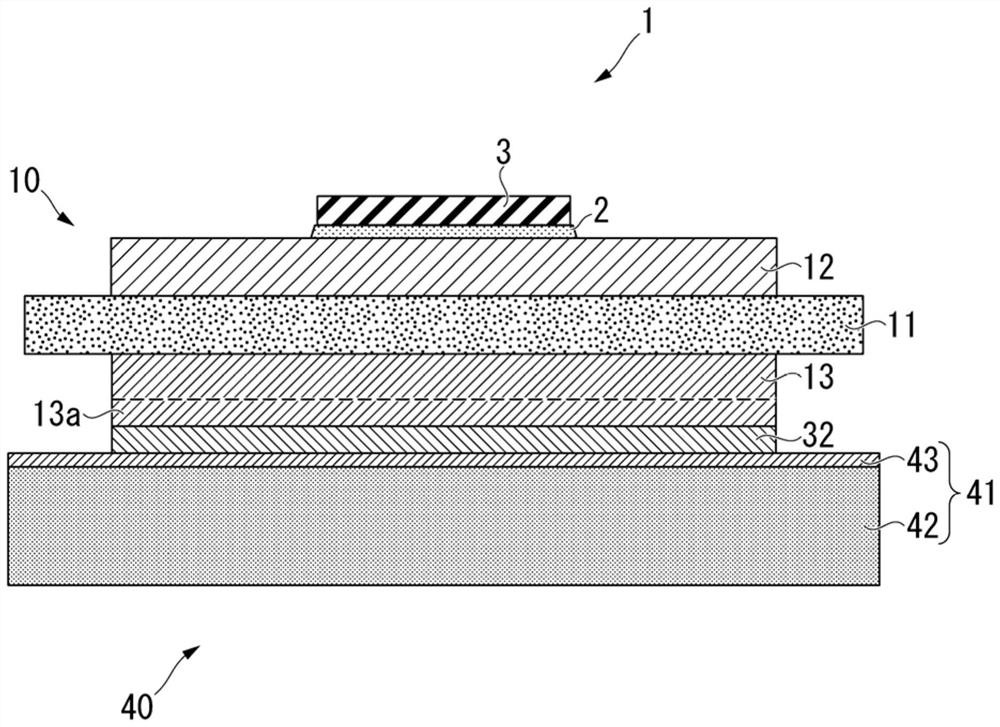

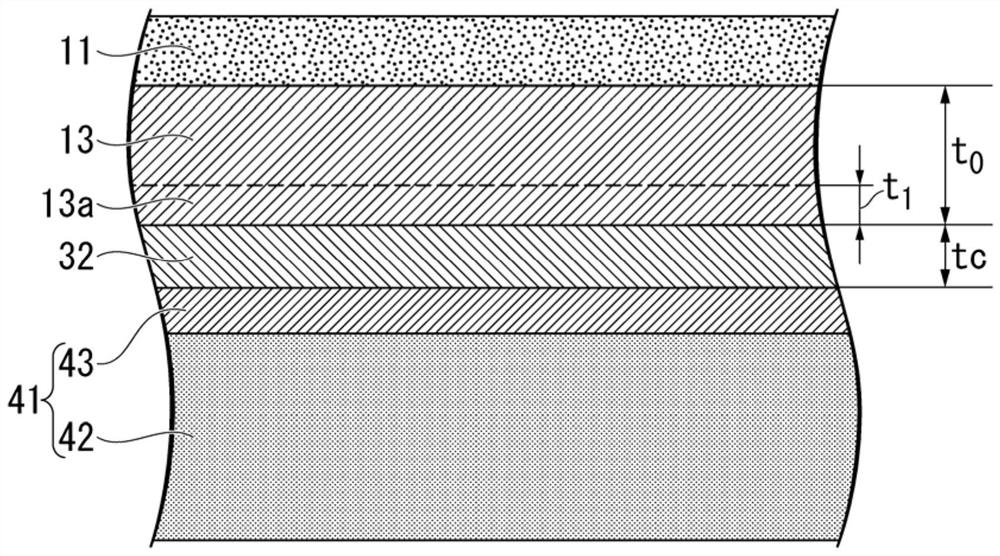

[0114] A confirmation experiment conducted to confirm the effectiveness of the present invention will be described below.

[0115] A circuit layer (37mm×37mm×thickness 0.4mm) made of aluminum (4N aluminum) with a purity of 99.99 mass% or more is formed on one surface of a ceramic substrate (40mm×40mm×thickness 0.635mm) made of aluminum nitride (AlN) , and a metal layer (37mm×37mm) of the material and thickness shown in Table 1 was formed on the other surface of the ceramic substrate. Al-7.5 mass %Si-0.01 mass %Mg brazing filler metal foil (thickness 15 micrometers) was used for bonding the ceramic substrate and the aluminum plate used as a circuit layer and a metal layer.

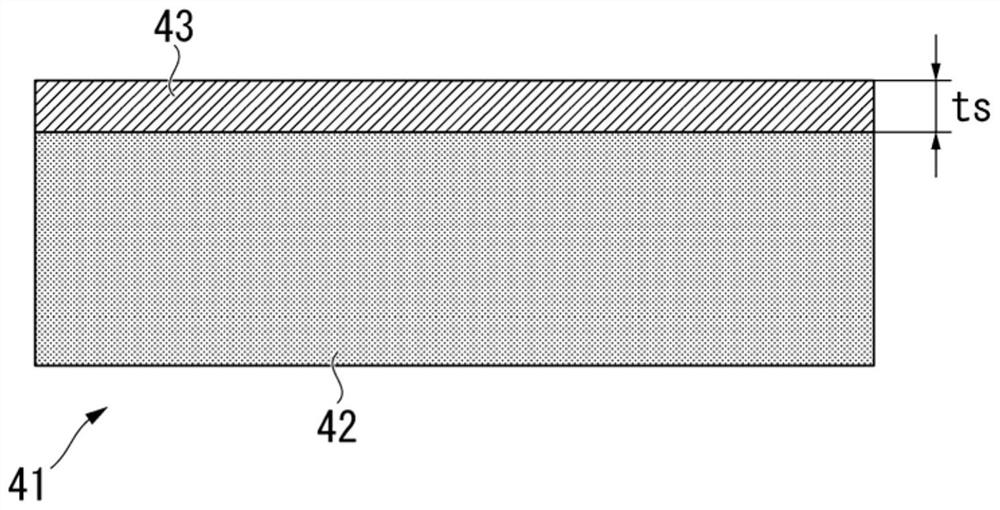

[0116] Then, the clad material having the structure shown in Table 1 was laminated on the surface of the aluminum plate serving as the metal layer on the opposite side to the ceramic substrate.

[0117] Then, heat treatment was performed according to the conditions shown in Table 1.

[0118] Then, a heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com