Cold-formed thin-walled steel-concrete combined bridge deck continuous device and construction method

A technology of cold-formed thin-walled steel and combined bridge deck, which is applied to bridges, bridge parts, bridge materials, etc., and can solve problems such as poor construction, poor durability of unbonded materials, and impact on bridge durability and ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

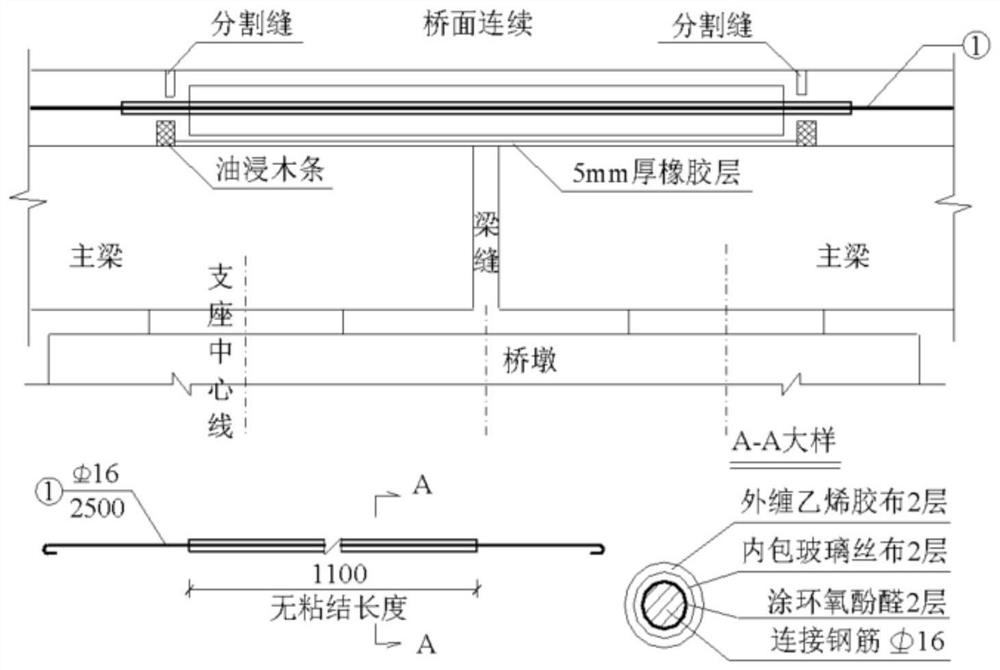

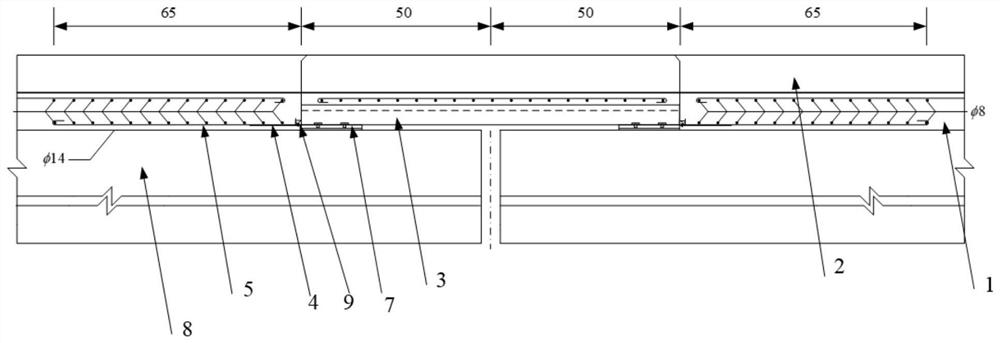

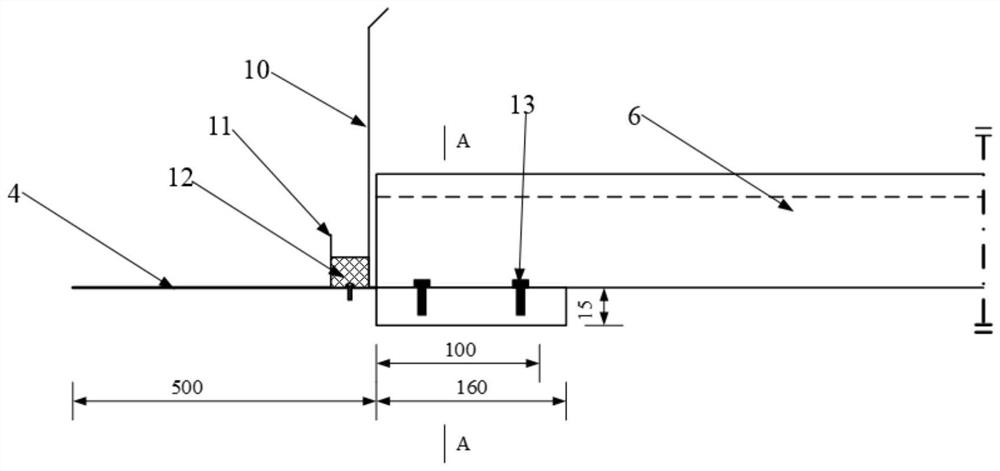

[0048] This embodiment provides a cold-formed thin-walled steel-concrete composite bridge deck continuous device applied to reinforced concrete simply supported girder bridges. Please refer to the attached Figure 2-4 .

[0049]The bridge deck continuous device is set on the reinforced concrete prefabricated T-beam 8, the upper layer of the prefabricated T-beam 8 is a 10cm thick C40 concrete pavement 1, and the top of the C40 concrete pavement 1 is a 10cm thick asphalt concrete pavement 2.

[0050] The bridge deck continuous device includes a steel standard section 3, the bottom of the steel plate standard section 3 is provided with an extended steel plate 4, and the extended steel plate 4 is connected with the concrete pavement layer 1, and the extended steel plate 4 is on the two sides of the steel plate standard section 3. End bottom transverse bridge direction welds a diameter 14mm, long 70cm longitudinal bridge direction connecting steel bar 5 every certain distance (for ...

Embodiment 2

[0061] This embodiment provides a continuous device and construction method for a cold-formed thin-walled steel-concrete composite bridge deck that can be quickly assembled without welding, including the following steps:

[0062] Step 1: Prefabricate steel standard sections and U-shaped drainage channels in the factory, including cutting C-shaped cold-formed thin-walled steel end limbs, specifically: C-shaped cold-formed thin-walled steel bottom plate at 200×50×15×3 Drill 4 bolt holes at each beam end, and at the same time drill four bolt holes at the corresponding positions on the support steel plate, then connect the C-shaped cold-formed thin-walled steel to the support steel plate with M14 hexagonal bolts, and connect the The steel standard section is assembled and spliced with self-tapping and self-drilling screws along the direction of the transverse bridge to form the required width, and then a 20mm thick foam glue is bonded on the outside of the support steel plate, wh...

Embodiment 3

[0070] Such as Figure 8-12 As shown, the finite element simulation model of the cold-formed thin-walled steel-concrete composite bridge deck continuous device is established, and the distribution of steel plates and material properties are simulated strictly according to the design conditions. By applying mid-span loads to the main girder, the results show that, Under the action of different mid-span loads, the maximum longitudinal stress of the surface concrete of the device of the present invention is about 1.5 MPa, indicating that the composite structure of the present invention has good vertical rigidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com