Bionic nano fiber material as well as preparation method thereof and application thereof

A fiber material and biomimetic nanotechnology, applied in the field of medical biomaterials, can solve problems such as weak mechanical force and chemical toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the biomimetic nanofiber material provided in this embodiment includes: compounding the silk fibroin-chitosan nanofiber membrane and the liquid crystal collagen, so that a part of the liquid crystal collagen is filled into the silk fibroin-chitosan nanofiber membrane In the fiber pores, another part of the liquid crystal collagen covers the surface of the silk fibroin-chitosan nanofiber membrane.

[0044] Concrete preparation steps are:

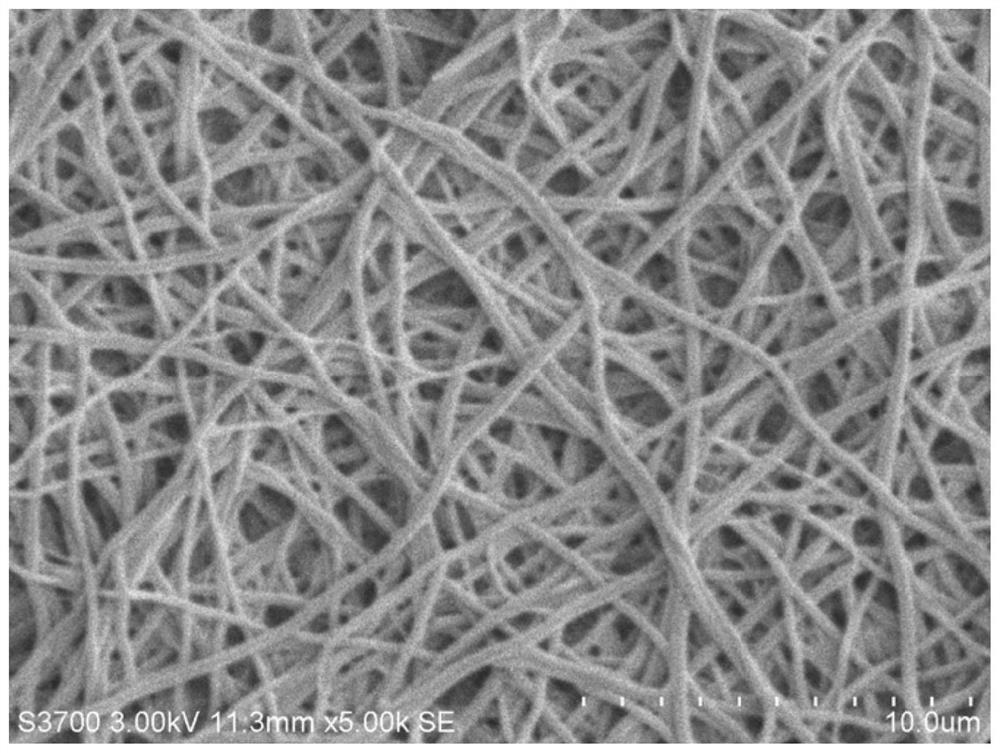

[0045] S1. Preparation of silk fibroin-chitosan nanofibers by electrospinning.

[0046] (1) Prepare a mixed electrospinning solution of silk fibroin and chitosan.

[0047] The mixture of chitosan and silk fibroin with a mass ratio of 0.23-0.25:1 is dissolved in a formic acid solution with a mass concentration of 80-98%, and stirred by magnetic force for 3-5 hours to obtain a uniformly dispersed mixed electrospinning solution. Preferably, the mass fraction of the obtained electrospinning solution is preferabl...

Embodiment 1

[0082] The preparation method of the biomimetic nanofiber material provided in this embodiment is specifically:

[0083] First prepare a high-concentration collagen solution:

[0084] The rat tail tendon was extracted, dissolved in 0.1% acetic acid solution for 48h, centrifuged at 4000rpm, 4°C for 30min, the supernatant was taken, and dialyzed for 7d. The dialysate was frozen overnight at -80°C, placed in a freeze dryer, and freeze-dried for 72 hours to obtain freeze-dried collagen. Dissolve freeze-dried collagen in 0.5mol / L acetic acid solution to prepare a 120mg / mL solution, stir magnetically at low temperature until dissolved, and use low-temperature interval ultrasonic method to disperse the collagen evenly. The collagen is dispersed evenly and then the spinning solution is prepared:

[0085] Extract regenerated silk fibroin: wash the cocoons and dissolve them in 0.5% Na 2 CO 3 Boil in aqueous solution to remove allergen sericin, dry and dissolve in CaCl 2 / C 2 h 5 ...

Embodiment 2

[0093] The preparation method of the biomimetic nanofiber material provided in this embodiment is specifically:

[0094] First prepare a high-concentration collagen solution:

[0095] The tail tendons of rats were extracted, dissolved in 0.1% acetic acid solution for 50 hours, centrifuged at 3800 rpm, 3°C for 25 minutes, and the supernatant was dialyzed for 7 days. The dialysate was frozen overnight at -85°C, placed in a freeze dryer, and freeze-dried for 76 hours to obtain freeze-dried collagen. Dissolve the freeze-dried collagen in 0.4mol / L acetic acid solution to prepare a 100mg / mL solution, stir magnetically at low temperature until dissolved, and use low-temperature interval ultrasonic method to disperse the collagen evenly. Collagen is dispersed evenly.

[0096] Next prepare the spinning solution:

[0097] Extract regenerated silk fibroin: wash the cocoons and dissolve them in 0.5% Na 2 CO 3 Boil in aqueous solution to remove allergen sericin, dry and dissolve in Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com