Electrolyte for Stable Lithium Metal Deposition and Its Application in Lithium Metal Batteries

A lithium metal battery and electrolyte technology, applied in non-aqueous electrolyte batteries, lithium batteries, secondary batteries, etc., can solve the problems of metal lithium anode dendrites and poor cycle performance, and achieve improved electrical performance, increased initial capacity and Cycling stability and the effect of improving lithium metal deposition stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Adopt the following method to configure electrolyte: in the glove box of argon atmosphere (H 2 O<0.1ppm), the organic solvent ethylene glycol dimethyl ether (DME): 1,3 dioxolane (DOL) (volume ratio) = 1:1 mixed with LiTFSI (1.0M), adding 1wt.% % anhydrous lithium nitrate and 1wt.% silicon nitride nanocrystals (the average particle size is 40nm), and fully stir evenly to obtain the lithium battery electrolyte of the present invention.

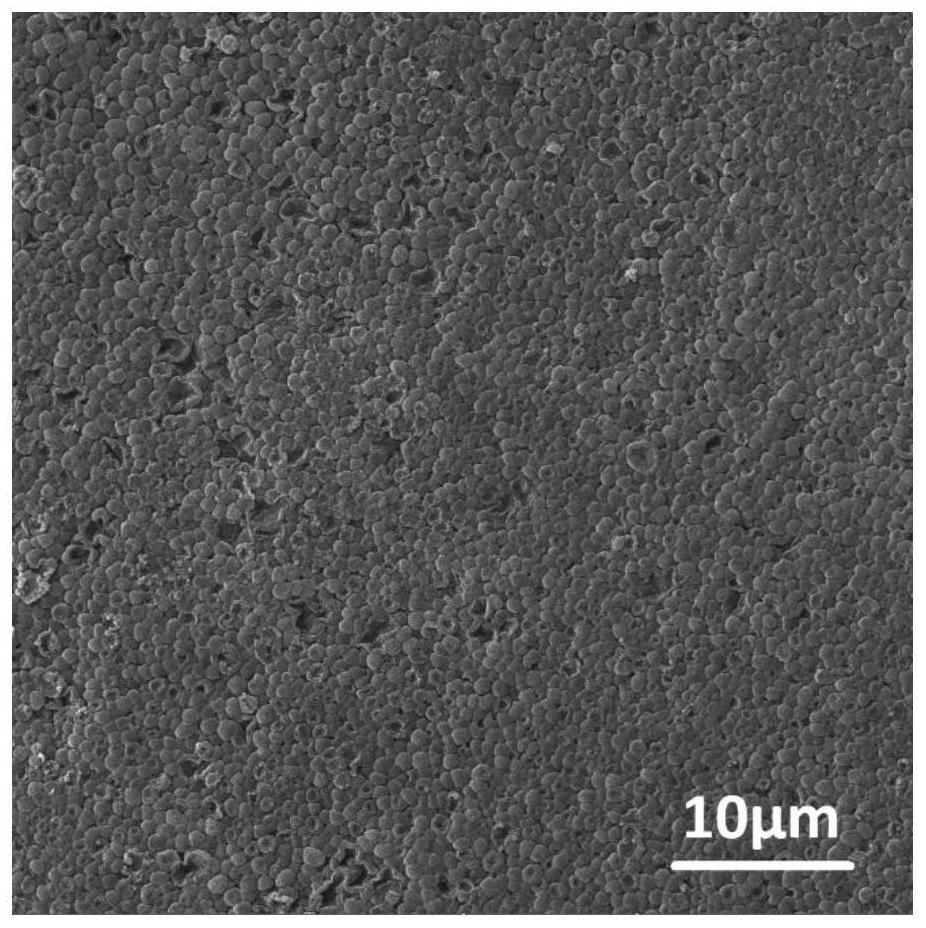

[0044] Battery assembly and testing: Copper foil is used as the positive electrode, lithium sheet is used as the negative electrode, Celgard2400 polypropylene separator is selected, and CR2025 button cells are assembled, and the prepared batteries are placed in a constant temperature room at 25°C for 12 hours, and then tested on the blue battery. The discharge test is carried out on the charge and discharge tester, and the test condition is 1mA / cm 2 , deposition for 120min. The surface morphology of lithium metal deposited on the curren...

Embodiment 2

[0062] Compared with Example 1, no auxiliary additives are added:

[0063] Adopt the following method to configure electrolyte: in the glove box of argon atmosphere (H 2 O<0.1ppm), the organic solvent ethylene glycol dimethyl ether (DME): 1,3 dioxolane (DOL) (volume ratio) = 1:1 mixed with LiTFSI (1.0M), adding 1wt.% Aluminum nitride nanocrystals (average particle size is 10nm), fully stirred evenly, used as electrolyte.

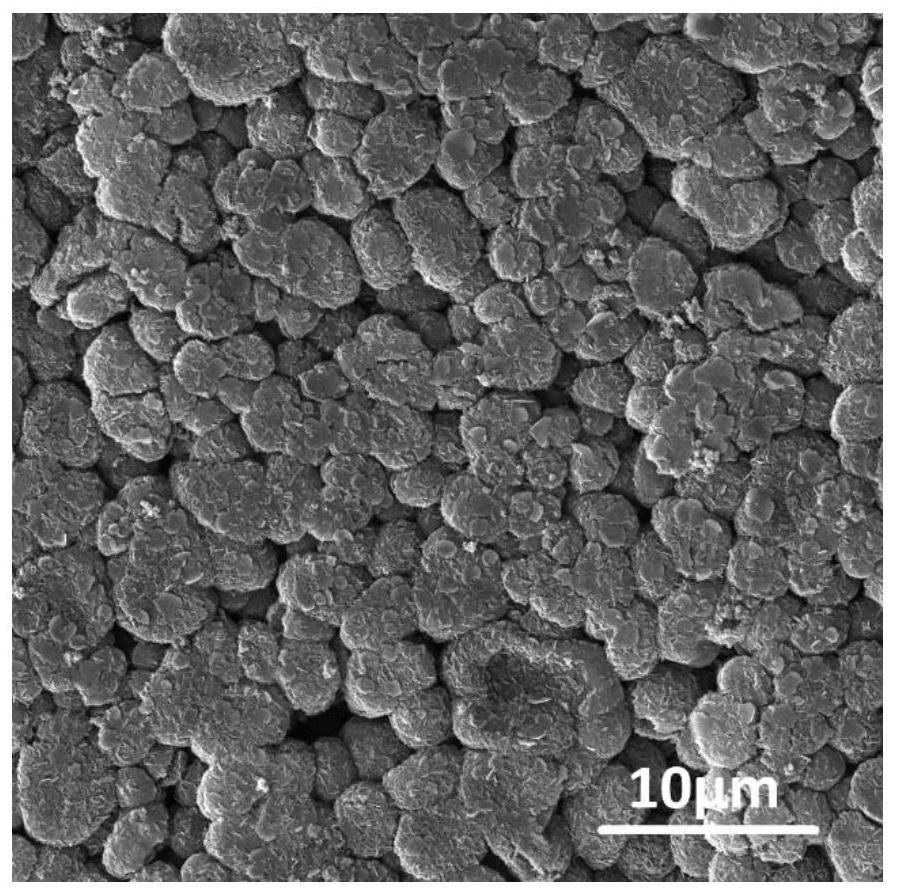

[0064] Battery assembly and testing: Copper foil is used as the positive electrode, lithium sheet is used as the negative electrode, Celgard2400 polypropylene separator is selected, and CR2025 button cells are assembled, and the prepared batteries are placed in a constant temperature room at 25°C for 12 hours, and then tested on the blue battery. The discharge test is carried out on the charge and discharge tester, and the test condition is 1mA / cm 2 , deposition for 120min. The surface morphology of lithium metal deposited on the current collector is as f...

Embodiment 3

[0070] Adopt the following method to configure electrolyte: in the glove box of argon atmosphere (H 2 (0<0.1ppm), mix the organic solvent lithium hexafluorophosphate and LiFSI (2.0M), add 2wt.% anhydrous lithium nitrate and 2wt.% aluminum nitride nanowires (diameter 5nm, wire length 200nm), fully stir , the lithium battery electrolyte of the present invention can be obtained.

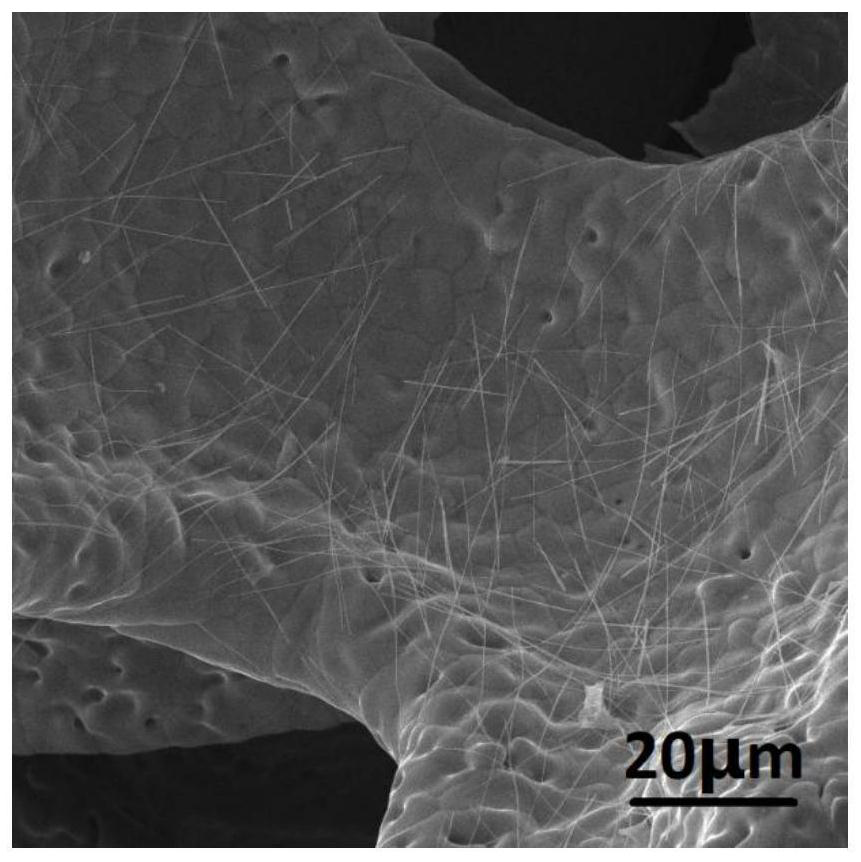

[0071] Battery assembly and testing: use copper foam as the positive electrode, lithium sheet as the negative electrode, and use glass fiber separators to assemble CR2032 button batteries. After the prepared batteries are placed in a constant temperature room at 25°C for 12 hours, one of them is disassembled. Battery, image 3 It is a scanning electron microscope picture of a copper foam collector, and a charge-discharge test cycle is performed on a blue electric test charge-discharge tester, and the test condition is 5mA / cm 2 , deposition for 30min. The obtained results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com