Reinforced concrete block, wall formed by masonry and masonry method

A reinforced, block technology, applied in the direction of walls, buildings, building materials, etc., can solve the problems of inability to take into account thermal insulation performance and strength performance, thermal insulation holes cannot be covered, and the masonry process is troublesome. High toughness and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

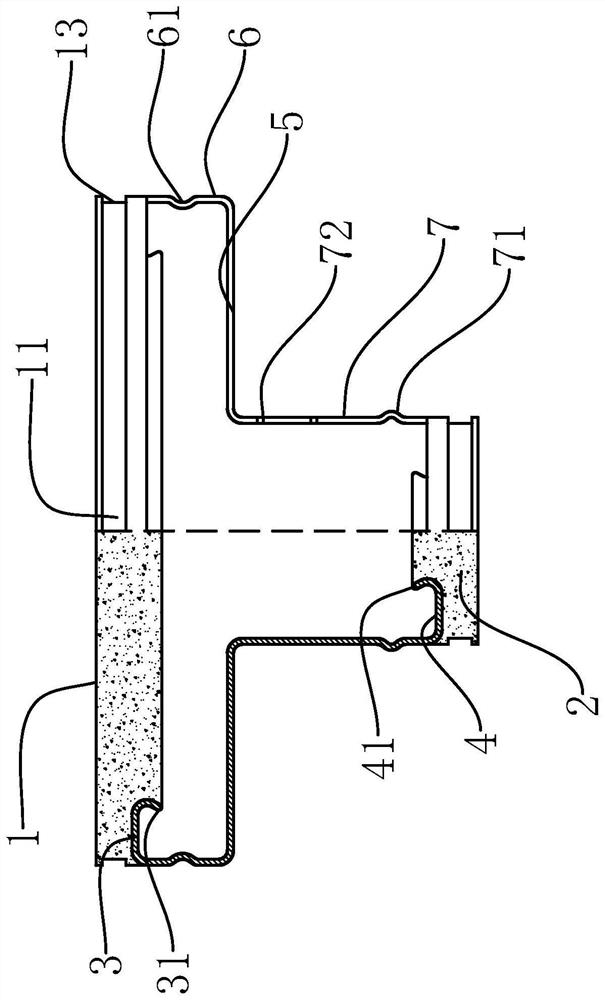

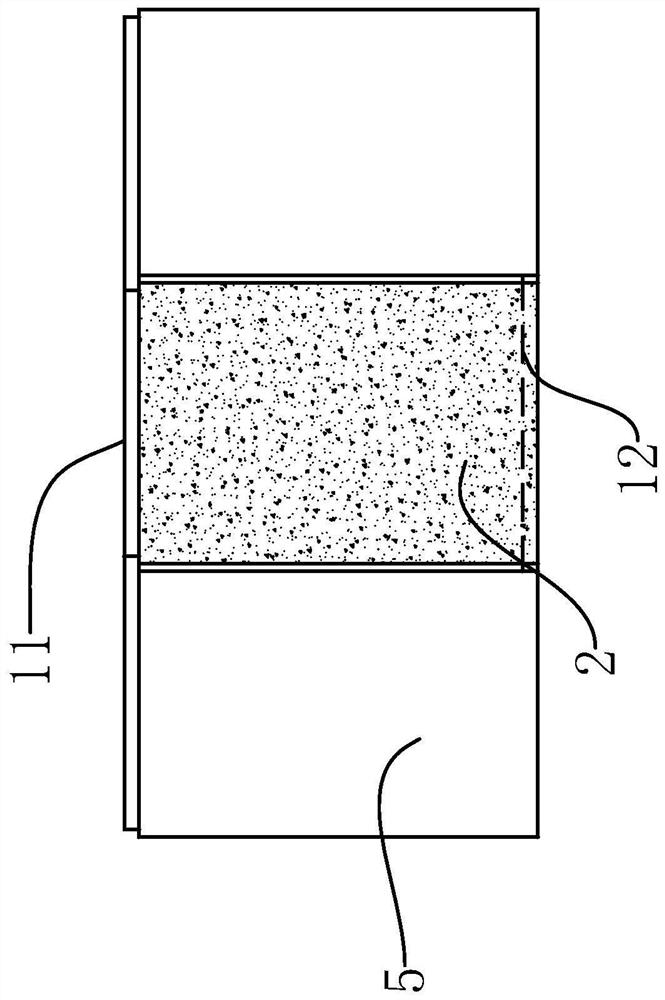

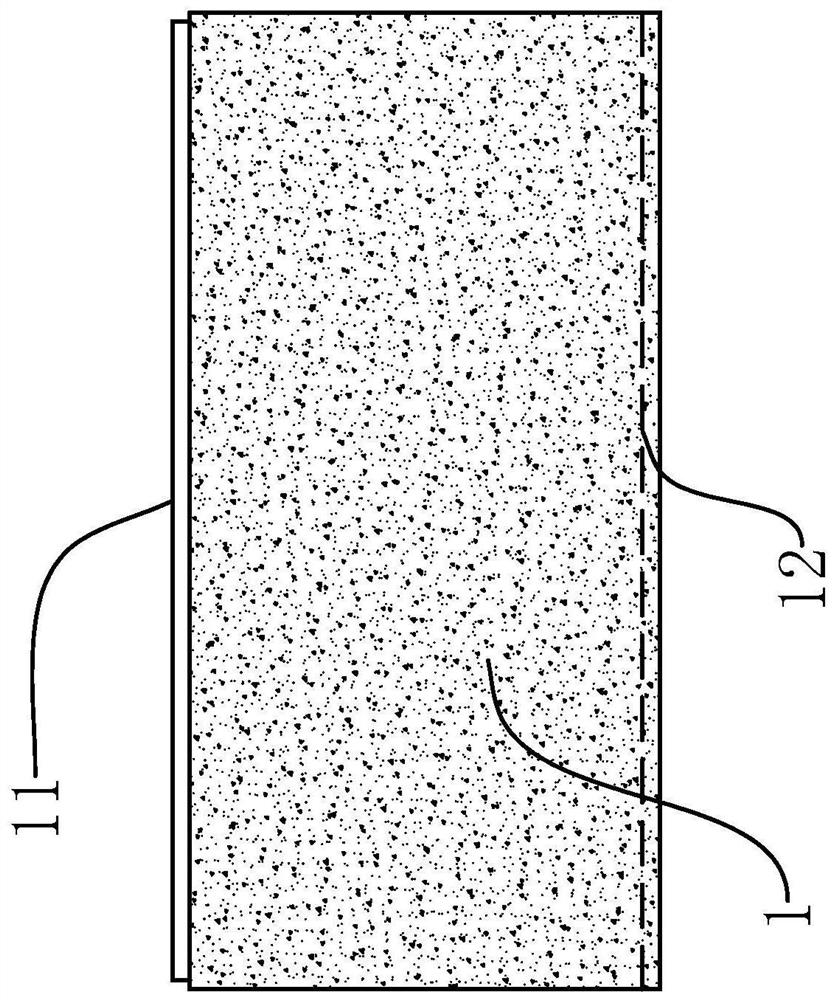

[0049] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0050] Such as Figure 1-6 As shown, a reinforced block of the present invention includes a main wall panel 1 and an auxiliary wall panel 2 made of concrete material and a rectangular plate structure, the outer side of the main wall panel 1 and the outer side of the auxiliary wall panel 2 are parallel to each other, A skeleton of steel structure is provided between the main wall panel 1 and the auxiliary wall panel 2. The skeleton is a hollow frame structure with a T-shaped cross section, and the vertical height of the skeleton perpendicular to the cross section of the skeleton, the vertical height of the main wall panel 1 and The auxiliary wall plates 2 have the same vertical height, and the skeleton includes the main fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com