Magnetic lubricating oil and preparation method thereof

A lubricating oil and magnetic technology, which is applied in the field of magnetic lubricating oil and its preparation, can solve problems such as leakage, device wear, and lubricating oil splashing, and achieve changes in oil viscosity, good viscosity-temperature performance, and good shear stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

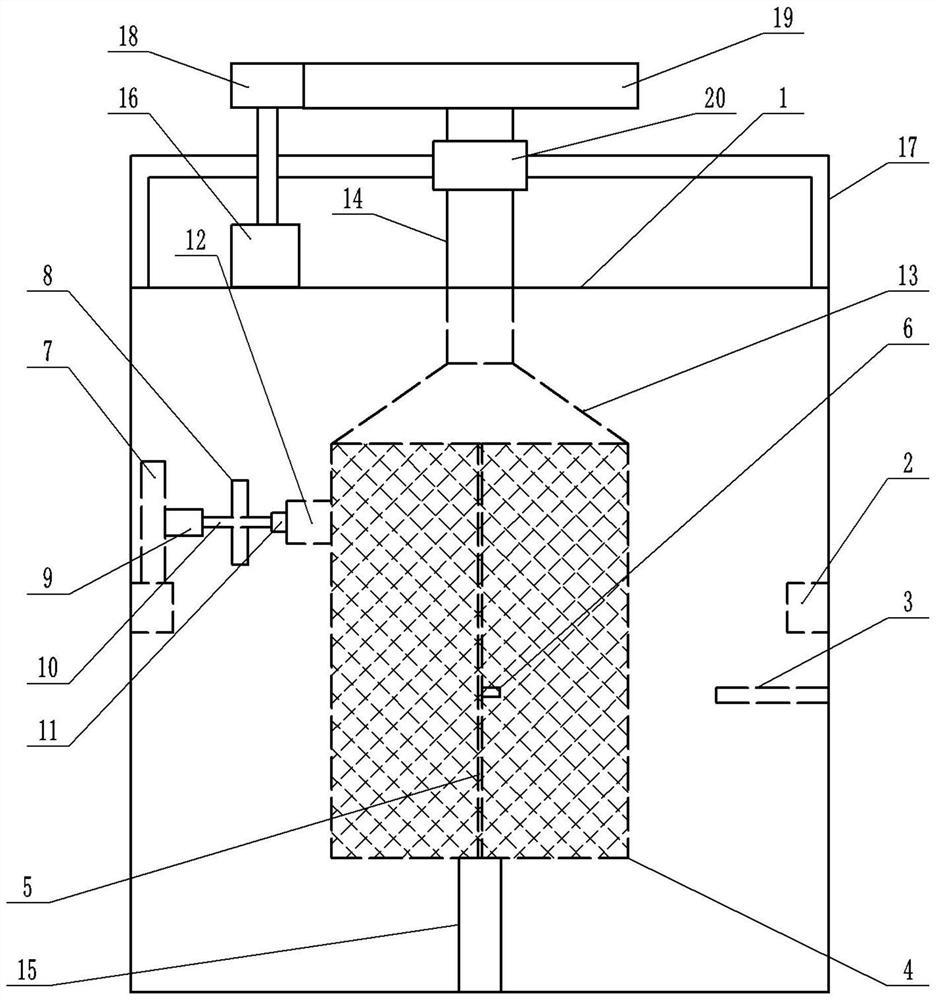

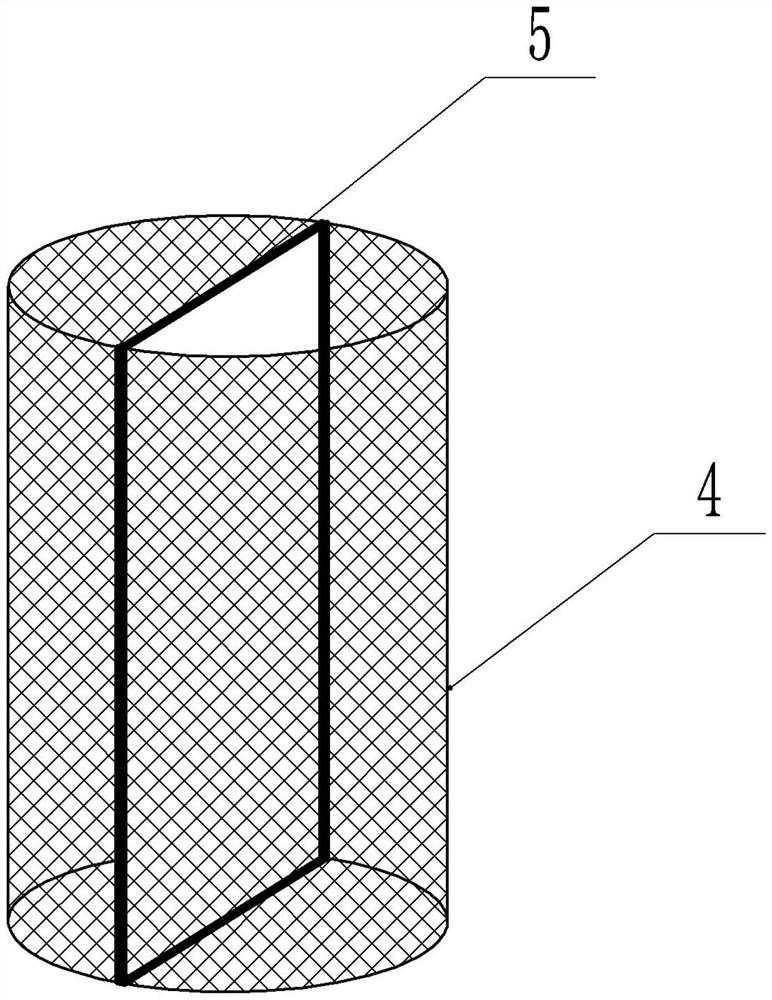

Method used

Image

Examples

Embodiment

[0030] A kind of magnetic lubricating oil, with 1kg as a part, including the following components: 40 parts of synthetic base oil, 46.2 parts of hydrogenated refined solvent oil, 12 parts of viscosity index improver, 0.5 part of pour point depressant, composite antioxidant and anticorrosion agent 0.3 parts, 0.5 parts of antioxidant, 0.5 parts of rust inhibitor, 0.002 parts of antifoaming agent, 1 part of magnetic particles.

[0031] Among them, synthetic base oil, hydrorefined solvent oil, viscosity index improver, pour point depressant, composite anti-oxidant and anti-corrosion agent, antioxidant, anti-rust agent, anti-foaming agent, and magnetic particles are polyalphaolefin PAO2, 40N respectively , Polymer polymethacrylate PAMA, low molecular polymethacrylate PAMA, bisoctyl zinc salt of sulfur phosphorus T204, 2,6-di-tert-butyl p-cresol T501, neutral dinonyl naphthalene sulfonate Barium acid T705A, silicon type and non-silicon type compound T901, carbonyl iron powder.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com