Glue solution spraying device special for pasting wall cloth

A technology of spraying device and glue, which is applied in the direction of construction and building structure, can solve the problems of low quality of roller coating, low efficiency of roller coating, low work efficiency, etc., and achieves short spraying time, improved work efficiency, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

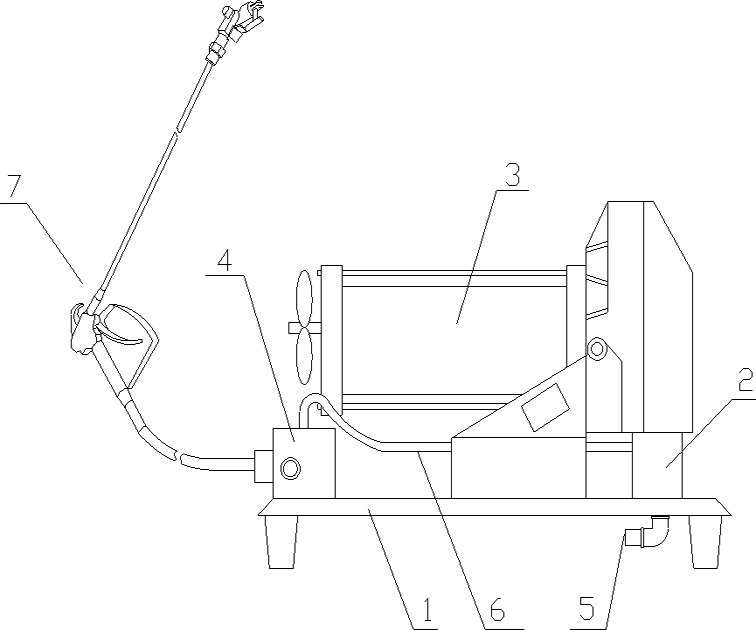

[0067] refer to figure 1 , a glue spraying device specially used for pasting wall coverings, including a base 1 and a pump body 2 arranged on the base 1, the pump body 2 is connected to a motor 3 through a reducer, and the motor 3 is connected to a pressure regulating mechanism 4. The inlet of the pump chamber of the pump body 2 is connected to the glue inlet through the rubber inlet pipe 5 , and the outlet of the pump chamber of the pump body 2 is connected to the spraying mechanism 7 through the rubber outlet pipe 6 .

[0068] Among them, the pump body 2 is a mechanical device for conveying rubber and pressurizing the rubber; the rubber in the present invention refers to water-soluble glue, especially water-soluble wall covering glue, for example: glutinous rice glue, this type of glue is water-soluble Good durability, environmental protection and stable performance, suitable for pasting various wallpapers, murals, wall coverings and heavy wallpapers, and can repair the edge...

Embodiment 2

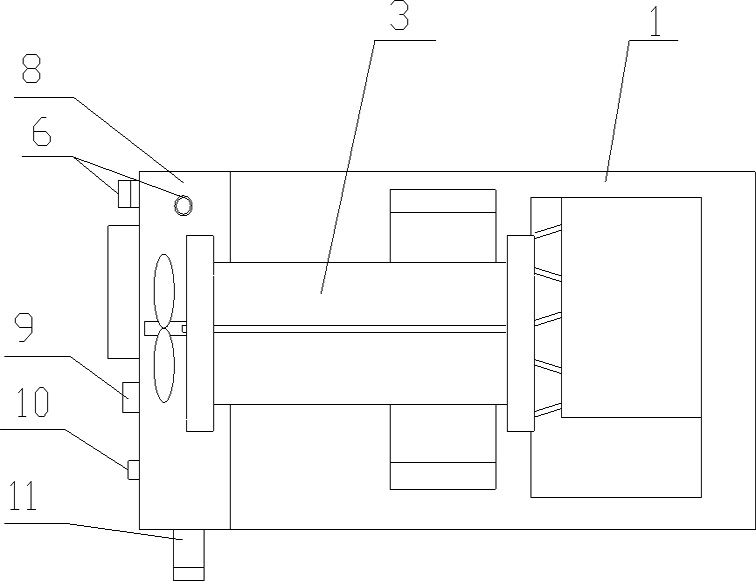

[0072] refer to Figure 1-3 , the glue spraying device specially used for pasting wall coverings described in this embodiment is different from the previous embodiments in that:

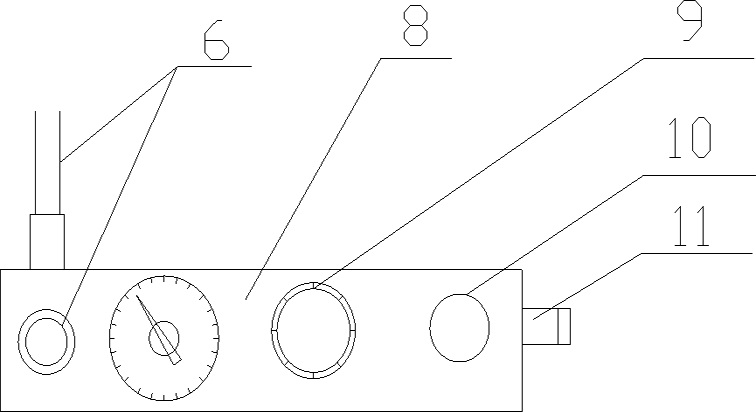

[0073] The pressure regulating mechanism 4 includes a pressure regulating pipe fitting 8. A pressure regulating valve 9, a pressure relief valve 10 and a pressure gauge are arranged on the pressure regulating pipe fitting 8. One end of the pressure regulating pipe fitting 8 communicates with the rubber outlet pipe 6, and the other A pressure relief port 11 is provided at one end.

[0074] The pressure regulating pipe fitting 8 is specifically: a cavity inside, the cavity communicates with the discharge pipe, and facilitates the pressure regulating valve 9, the pressure relief valve 10 and the pressure gauge to communicate with the cavity.

[0075] Pressure regulating valve 9, also known as pressure control valve, can adopt electric pressure regulating valve 9, manual pressure regulating valve 9, hyd...

Embodiment 3

[0080] refer to Figure 1-7 , the glue spraying device specially used for pasting wall coverings described in this embodiment is different from the previous embodiments in that:

[0081] The reducer includes a driving gear connected to the motor 3 shaft, and a driven gear connected to the driving gear, and the driven gear is connected to a plunger 34 through an eccentric wheel 33 .

[0082] This embodiment provides a specific connection mode of the reducer when the pump body 2 is specifically a plunger 34 pump. The speed reducer at least includes a driving gear and several driven gears connected with the driving gear.

[0083] The plunger 34 pump is usually used as an oil supply device and is often used in the lubrication system of the machine. In the present invention, the plunger 34 pump is used for conveying the water-soluble adhesive and provides pressurization for the water-soluble adhesive.

[0084] The plunger 34 pump comprises an upper cylinder body 35, a lower cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com