Steel plate for ship and segregation-preventing production method thereof

A production method and a technology for ships, which are applied in the production field of steel plates for ships and avoid segregation, can solve the problems of low pass rate of steel grades, impact samples, fracture separation, etc., achieve improvement of steel plate segregation, increase heating temperature, avoid The effect of segregation formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

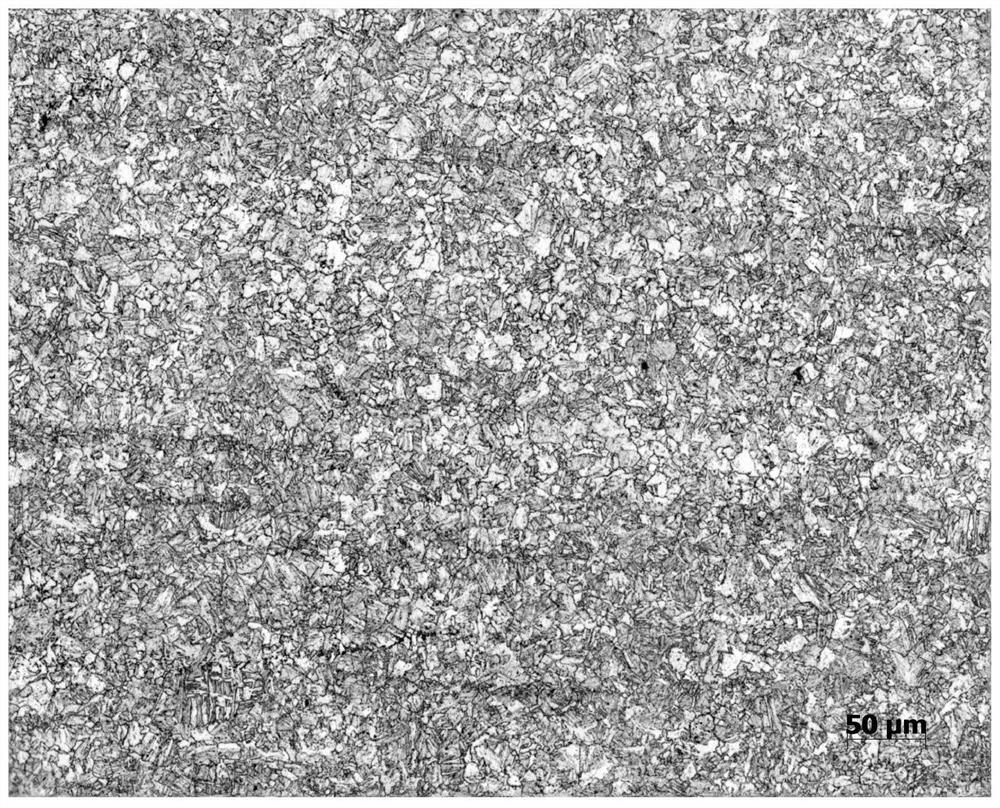

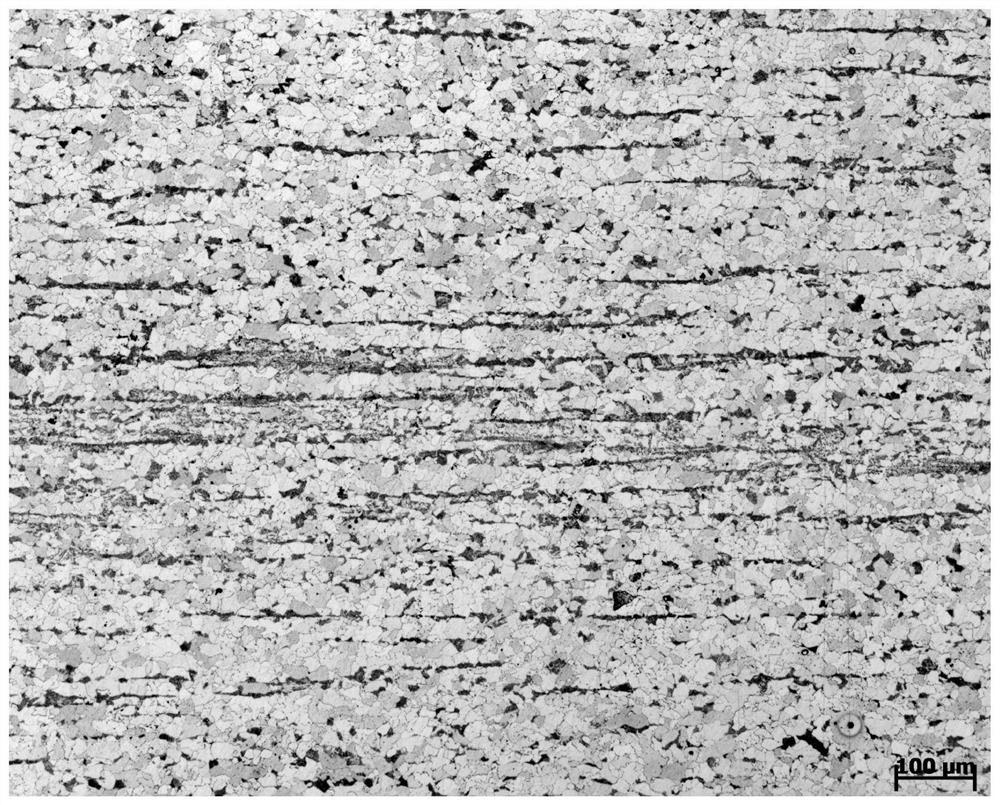

Image

Examples

Embodiment 1

[0024] Embodiment 1: After the billet continuous casting is cut, it is put into the heat preservation pit, and the temperature of the heat preservation pit is controlled at 650° C., and the heat preservation is carried out for 72 hours.

[0025] Put the 220mm thick continuous casting billet into the heating furnace for reheating, the heating temperature is 1200°C, the total time in the furnace is 352min, the soaking time is 73min, and rolled into a rolled piece of 12×2000×Lmm (thickness, width, length), and finally The rolling temperature is 900°C, and the redness temperature is 680°C. The steel plate is qualified by NB / T 47013 T1T1 flaw detection.

[0026] The 12×2000×8000mm steel plate was quenched and tempered at high temperature, the quenching heating temperature was 900°C, the total quenching time in the furnace was 30min, the tempering heating temperature was 665°C, and the total tempering time in the furnace was 90min.

[0027] The test results of mechanical properties...

Embodiment 2

[0028] Example 2: Similarly, after the continuous casting and cutting of the blank, it is put into the heat preservation pit, and the temperature of the heat preservation pit is controlled at 650° C., and the heat preservation is carried out for 80 hours.

[0029] Put the 220mm thick continuous casting billet into the heating furnace for reheating, the heating temperature is 1240°C, the total time in the furnace is 385min, the soaking time is 83min, and rolled into a rolled piece of 15×2000×Lmm (thickness, width and length). The rolling temperature is 920°C, and the redness temperature is 675°C. The steel plate is qualified by NB / T 47013 T1T1 flaw detection.

[0030] The 15×2000×8000mm steel plate was quenched and tempered at high temperature, the quenching heating temperature was 920°C, the total quenching time in the furnace was 35min, the tempering heating temperature was 673°C, and the total tempering time in the furnace was 106min.

[0031] The test results of mechanical...

Embodiment 3

[0032] Embodiment 3: After the billet continuous casting is cut, it is put into the heat preservation pit, and the temperature of the heat preservation pit is controlled at 660° C., and the heat preservation is carried out for 83 hours.

[0033] Put the 220mm thick continuous casting billet into the heating furnace for reheating, the heating temperature is 1230°C, the total time in the furnace is 390min, the soaking time is 60min, and rolled into a rolled piece of 16×2000×Lmm (thickness, width, length). The rolling temperature is 910°C, and the redness temperature is 670°C. The steel plate is qualified by NB / T 47013 T1T1 flaw detection.

[0034] The 16×2000×8000mm steel plate was quenched and tempered at high temperature, the quenching heating temperature was 910°C, the total quenching time in the furnace was 20min, the tempering heating temperature was 660°C, and the total tempering time in the furnace was 110min.

[0035] The test results of mechanical properties are: yield...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com