Sodium lauroyl sarcosinate-bacitracin compound and composite oil displacement agent

A technology of sodium lauroyl sarcosinate and composite oil displacement agent, which is applied in the direction of drilling compositions, peptides, hybrid peptides, etc., which can solve the problem of reducing the effect of microbial oil displacement, the inability to achieve microbial oil displacement, and the weakening of microbial motility and other problems, to achieve the effect of improving synergistic reaction efficiency, operability and applicability, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

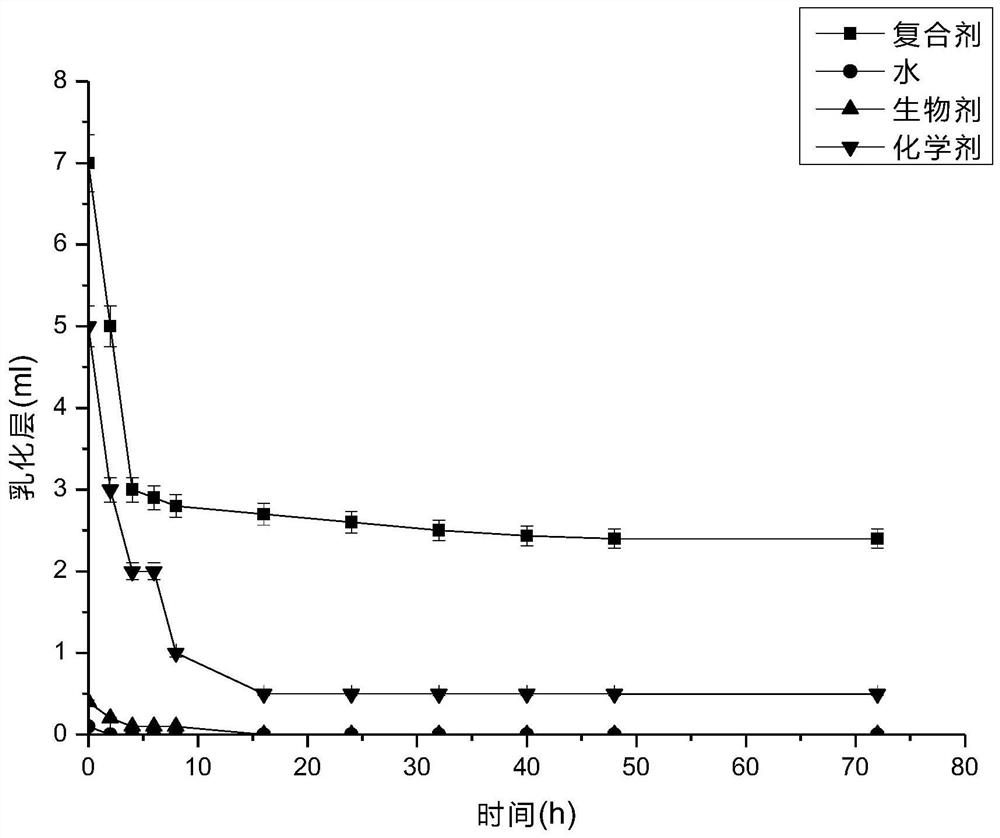

[0070] This embodiment provides a kind of microbial-chemical composite oil displacement agent, and it is prepared through the following steps:

[0071] (1) Add 200mL of the culture medium of the inoculated strain to a 500mL Erlenmeyer flask, place it in an air-bath shaker at 65°C and 170r / min for cultivation, and when the bacteria grow to the late logarithmic period, centrifuge at 8000r / min for 15min to collect the cells , washed with dilute sulfuric acid (pH value = 2) to remove impurities, and suspend the bacteria to make a suspension (1cm cuvette) with an absorbance value of 1 at a wavelength of 600nm. Centrifuge for 10 minutes to collect the lower layer of bacteria;

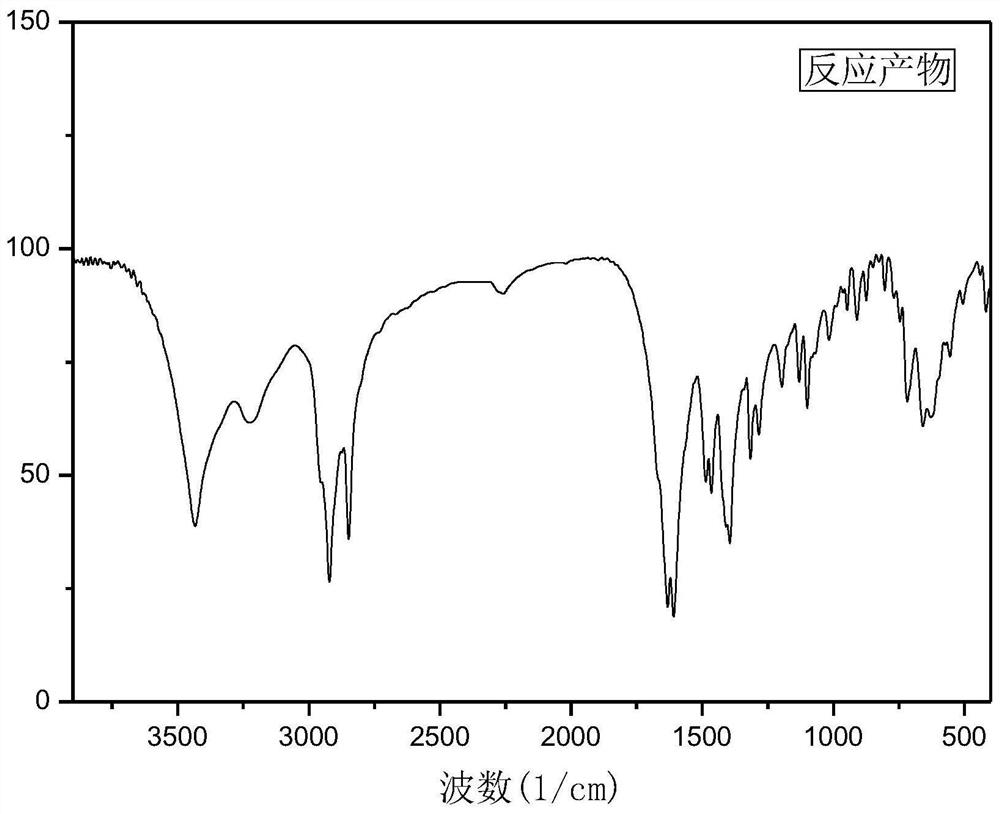

[0072] (2) Bacteria were eluted with water at 40°C for 12 hours, centrifuged, and the upper capsule solution was taken for chromatographic separation and purification to obtain the bacitracin compound (during the chromatographic separation, the retention time of the upper capsule solution was determined accor...

Embodiment 2

[0079] This embodiment provides a kind of microbial-chemical composite oil displacement agent, and it is prepared through the following steps:

[0080] (1) Add 200mL of the culture medium of the inoculated strain to a 500mL Erlenmeyer flask, place it in an air-bath shaker at 65°C and 170r / min for cultivation, and when the bacteria grow to the late logarithmic period, centrifuge at 8000r / min for 15min to collect the cells , washed with dilute sulfuric acid (pH value = 2) to remove impurities, and suspend the bacteria to make a suspension (1cm cuvette) with an absorbance value of 1 at a wavelength of 600nm. Centrifuge for 10 minutes to collect the lower layer of bacteria;

[0081] (2) Bacteria were eluted with water at 40°C for 12 hours, centrifuged, and the upper capsule solution was taken for chromatographic separation and purification to obtain the bacitracin compound (during the chromatographic separation, the retention time of the upper capsule solution was determined accor...

Embodiment 3

[0085] This embodiment provides a kind of microbial-chemical composite oil displacement agent, and it is prepared through the following steps:

[0086] (1) Add 200mL of the culture medium of the inoculated strain to a 500mL Erlenmeyer flask, place it in an air-bath shaker at 65°C and 170r / min for cultivation, and when the bacteria grow to the late logarithmic period, centrifuge at 8000r / min for 15min to collect the cells , washed with dilute sulfuric acid (pH value = 2) to remove impurities, and suspend the bacteria to make a suspension (1cm cuvette) with an absorbance value of 1 at a wavelength of 600nm. Centrifuge for 10 minutes to collect the lower layer of bacteria;

[0087](2) Bacteria were eluted with water at 40°C for 12 hours, centrifuged, and the upper capsule solution was taken for chromatographic separation and purification to obtain the bacitracin compound (during the chromatographic separation, the retention time of the upper capsule solution was determined accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com