Grinding machine for gear machining

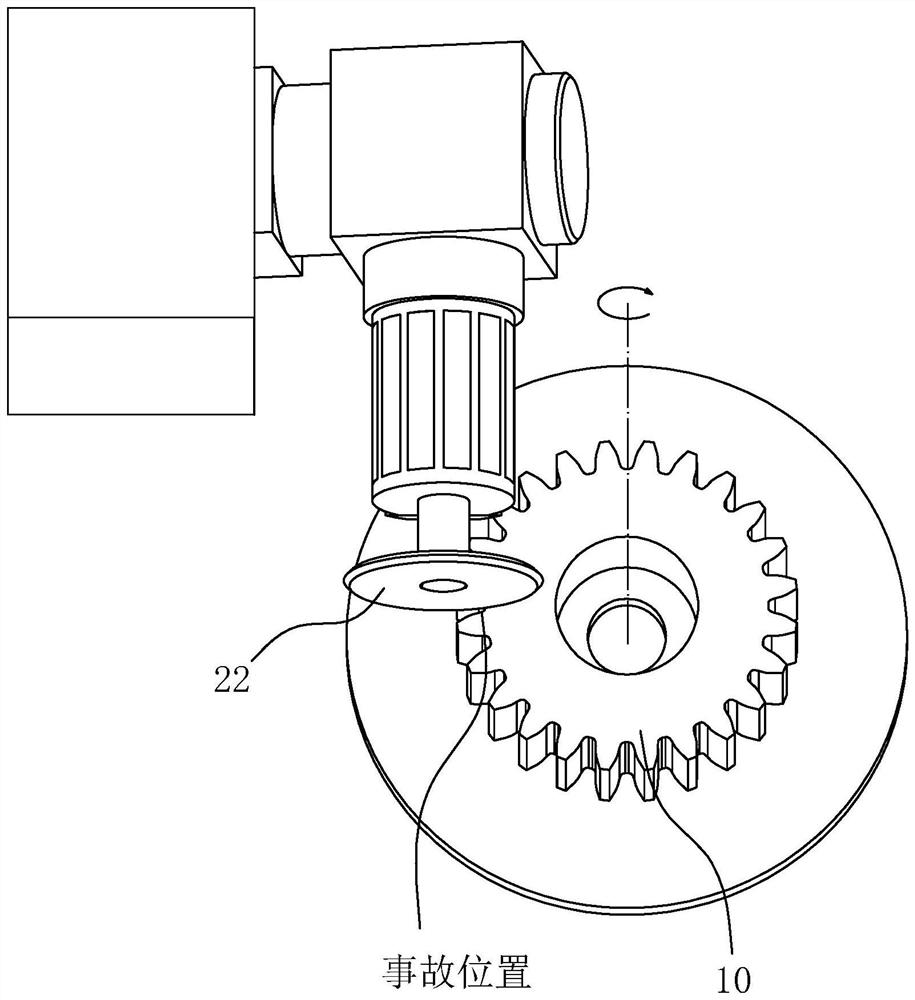

A technology for gears and grinding machines, applied in the field of gear processing, can solve the problems of grinding wheel 22 breaking and flying out, and achieve the effect of reducing accident probability, improving grinding efficiency, and reducing the accident probability of grinding wheel breaking or flying out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

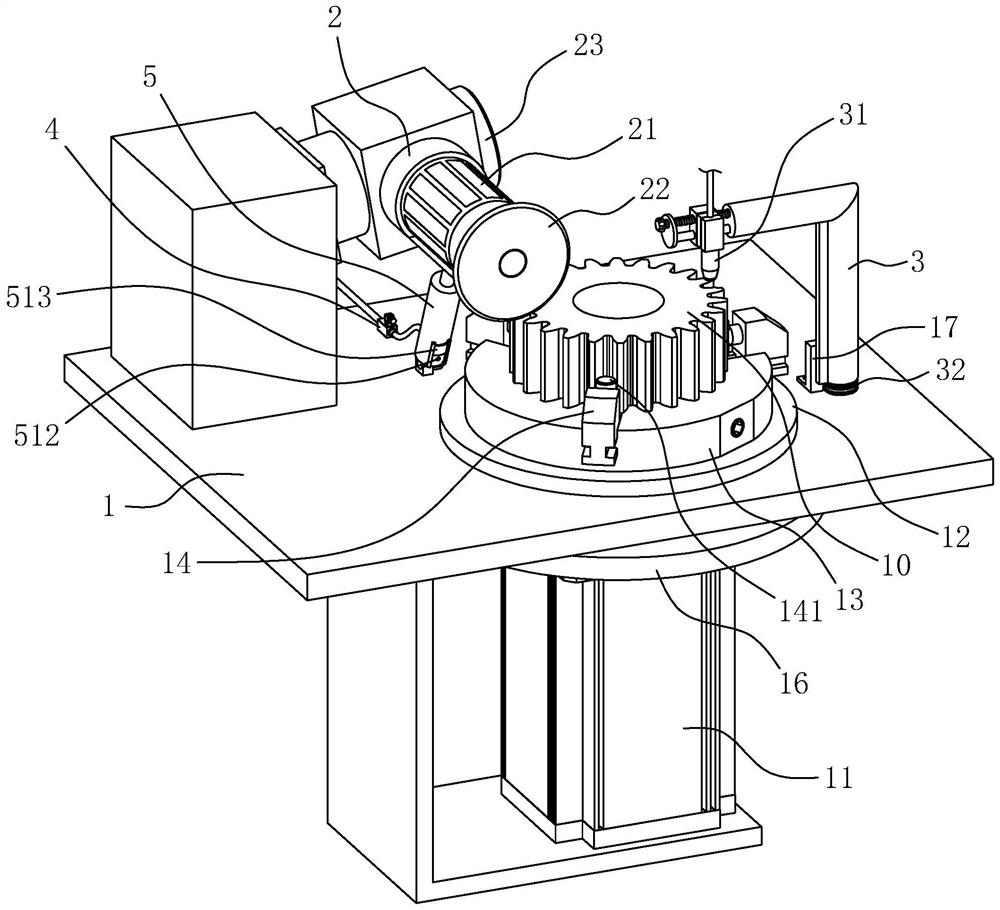

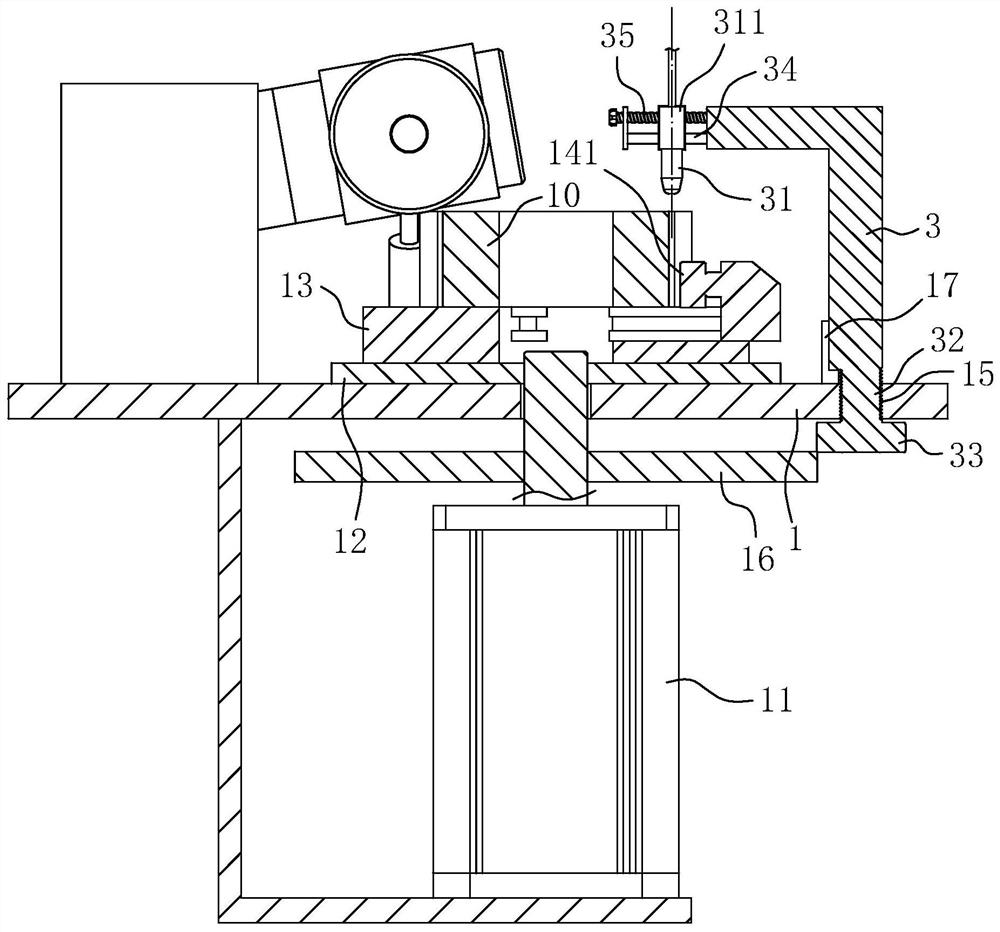

[0036] The following is attached Figure 2-6 The application is described in further detail.

[0037] The embodiment of the present application discloses a grinding machine for gear processing. refer to figure 2 and image 3 , the grinding machine for gear processing comprises a base 1, the base 1 is provided with a motor-11, a rotating seat 12 driven by the motor-11, and the rotation axis of the rotating seat 12 is along the vertical direction; the rotating seat 12 is fixed with a chuck 13, The chuck 13 is a common three-jaw chuck, and the rotation axis of the chuck 13 is the central axis. The chuck 13 includes three claws 14 distributed along the circumferential direction. Base 1 is also connected with swing arm 2 by hinge shaft one 23 rotation, swing arm 2 is provided with motor two 21, the grinding wheel 22 driven by motor two 21 to rotate, grinding wheel 22 is positioned at chuck 13 tops, and chuck 13 is installed After clamping the gear workpiece 10, the grinding whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com