An energy-saving chemical distillation tower for the production of hydroxypropyl methylcellulose

A hydroxypropyl methylcellulose, energy-saving technology, which is applied in the field of chemical distillation towers for energy-saving hydroxypropyl methylcellulose production, can solve the problem of reducing steam rising efficiency, reducing the distillation effect of chemical distillation towers, and not being able to Guarantee the protection of cages and other issues to achieve the effect of improving the lifting efficiency, improving the distillation effect, and preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

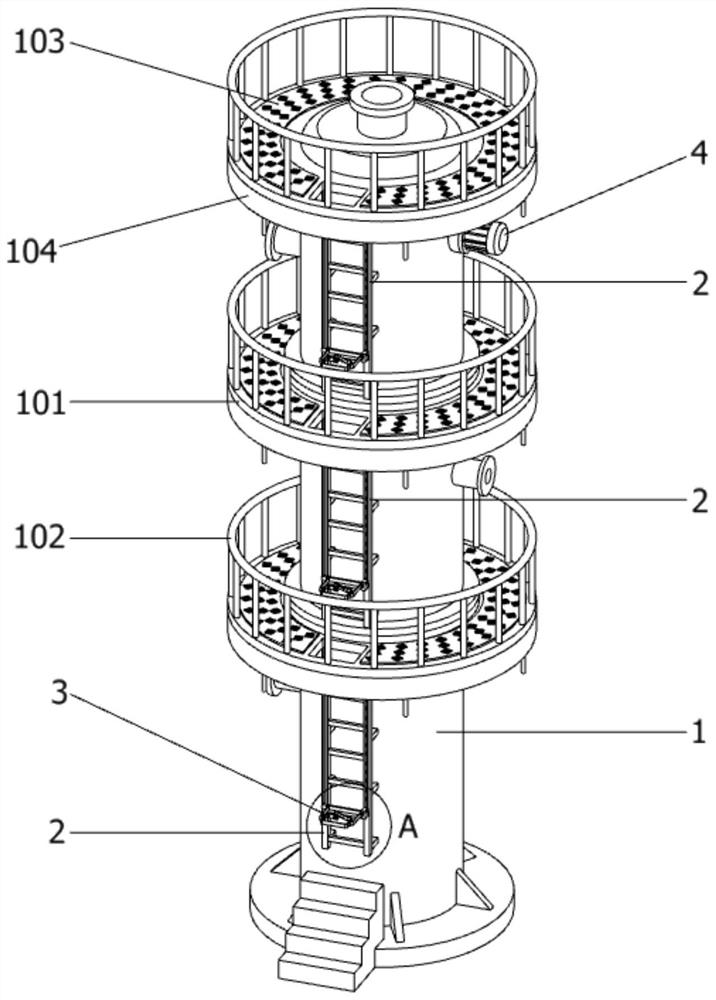

[0036] as attached figure 1 to attach Figure 11 Shown:

[0037] The invention provides an energy-saving chemical distillation tower for producing hydroxypropyl methylcellulose, which includes: a tower body 1, the upper and lower parts on the left side of the tower body 1 are respectively provided with a return pipe and a steam inlet, and the right side of the tower body 1 There is a liquid inlet in the middle. The tower body 1 includes a maintenance platform 101, an annular guardrail 102, an anti-skid rubber pad 103 and a drainage plate 104. There is a stepped structure at the bottom of the front side of the tower body 1. Each maintenance platform 101 is welded with an annular guardrail 102 at the edge of the upper end surface of each maintenance platform 101, and an anti-skid rubber pad 103 is pasted on the upper surface of each maintenance platform 101, and each maintenance platform 101 is equipped with a There is a diversion plate 104, the diversion plate 104 is a ring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com