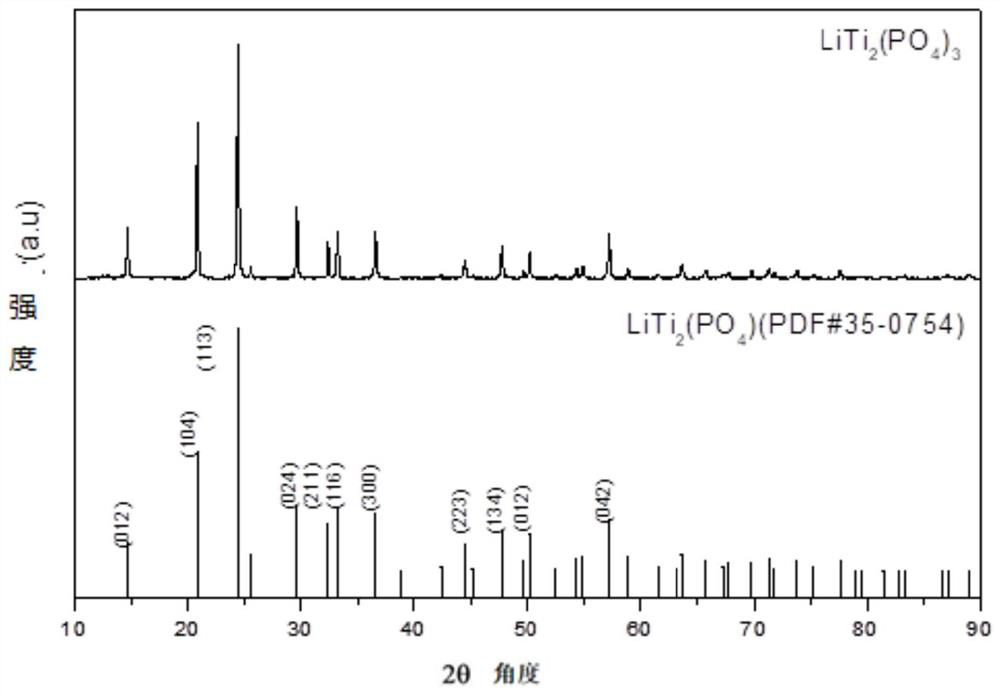

Titanium phosphate composite material and preparation method and application thereof

A composite material, titanium phosphate technology, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of material waste, air pollution, wall hanging, etc., and achieve simple process, easy operation, and convenient post-processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

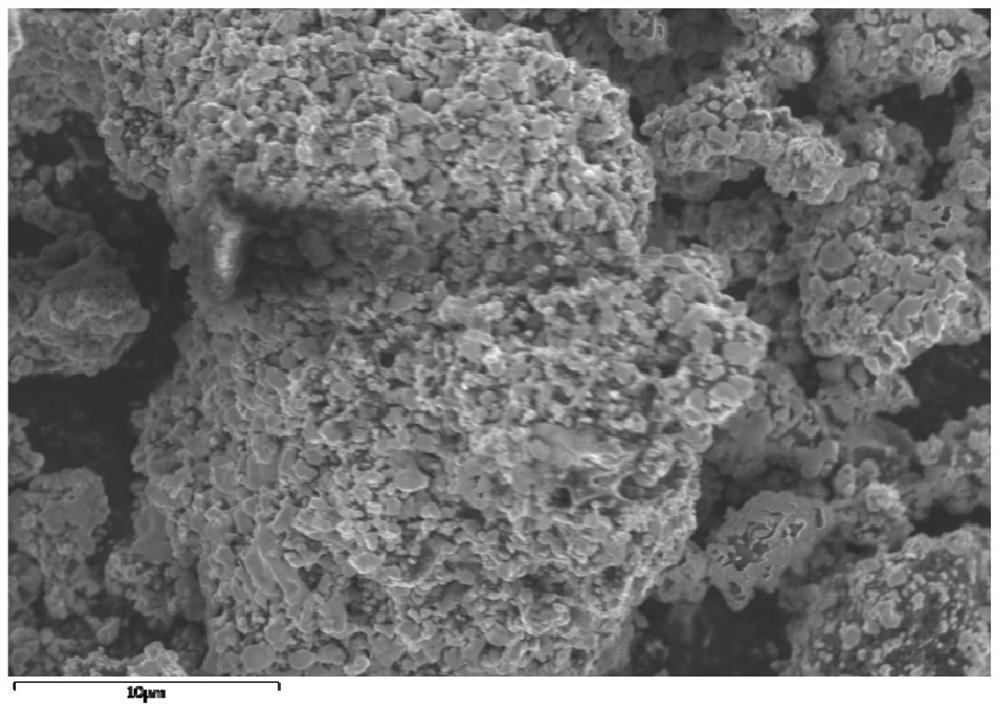

[0098] The preparation of embodiment 1 carbon / titanium phosphate composite material

[0099] Step A: After weighing the lithium source, titanium source, phosphorus source, and carbon source in proportion, place them in a ball mill tank for full ball milling, and obtain material A after ball milling and mixing;

[0100] Among them, the lithium source, titanium source, phosphorus source, carbon source and the amount used are: lithium carbonate 7.4g, titanium dioxide 32.0g, ammonium dihydrogen phosphate 69.0g, sucrose 22.0g;

[0101] The milling time is 3 hours, the rotation speed is 200r / min, and the ball-to-material ratio is 7:1.

[0102] Step B: Add additive aqueous solution to material A, and then stir for a long time to make it fully mixed, and obtain pasty material B after mixing;

[0103] Wherein, the additive used is CMC, the mass concentration of its aqueous solution is 1%, the total mass of the aqueous solution is 30 g, and the stirring time is 3 hours.

[0104] Step ...

Embodiment 1

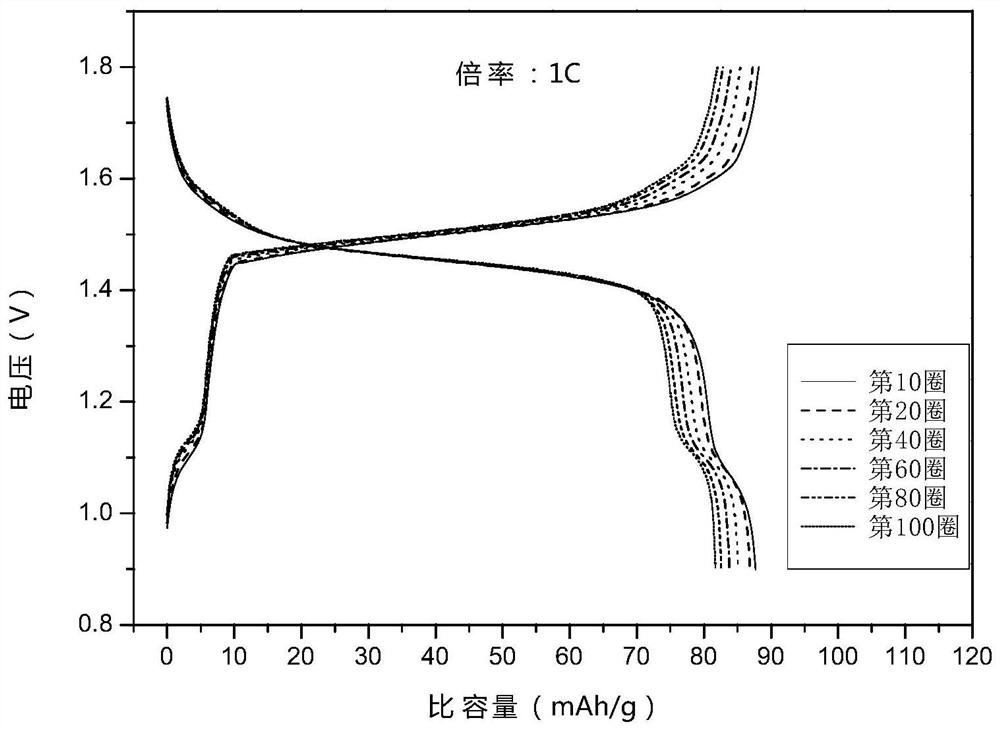

[0116] Embodiment 1 Half-cell assembly:

[0117] Half-cell structure composition

[0118] Electrolyte: 2M lithium sulfate (Li 2 SO 4 ) aqueous solution

[0119]Diaphragm: glass fiber filter paper (porosity below 1 micron, thickness about 260 microns)

[0120] Negative electrode: activated carbon cloth

[0121] Positive electrode: active material is carbon / titanium phosphate composite material

[0122] Positive electrode preparation process: Add the active material, conductive agent SP, and binder PTFE into the ethanol solution at a mass ratio of 7:2:1, mix and stir to form a slurry, coat it on the stainless steel mesh, and then dry it in vacuum. The electrode area is about 1.5cm 2 , the areal density of the active substance is about 1-2 mg cm -2 .

[0123] The battery used is a CR2032 button battery.

[0124] Wherein, the positive active material is denoted as half-cell 1 by the half-cell provided by embodiment I; the half-cell provided by embodiment II is denoted as ...

Embodiment 2

[0125] Example 2 full battery assembly:

[0126] Full battery structure

[0127] Electrolyte: lithium sulfate (Li 2 SO 4 ) saturated aqueous solution

[0128] Diaphragm: glass fiber filter paper (porosity below 1 micron, thickness about 260 microns)

[0129] Negative electrode active material: carbon / titanium phosphate composite material

[0130] Positive electrode active material: lithium manganate

[0131] The production process of the negative electrode sheet: the active material, the conductive agent SP, and the binder PTFE are mixed in an ethanol solution in a mass ratio of 7:2:1 to form a slurry, coated on a stainless steel mesh, and then vacuum-dried. The electrode area is about 1.5cm 2 , the areal density of the active substance is about 1-2 mg cm -2 .

[0132] The production process of the positive electrode sheet: the active material, the conductive agent SP, and the binder PTFE are mixed in an ethanol solution in a mass ratio of 8:1:1 to form a slurry, coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com